Paper diaper antibacterial plastic packaging bag and preparation method thereof

A technology of antibacterial plastics and diapers, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor antibacterial ability and easy breeding of bacteria, and achieve the effect of improving structural stability and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

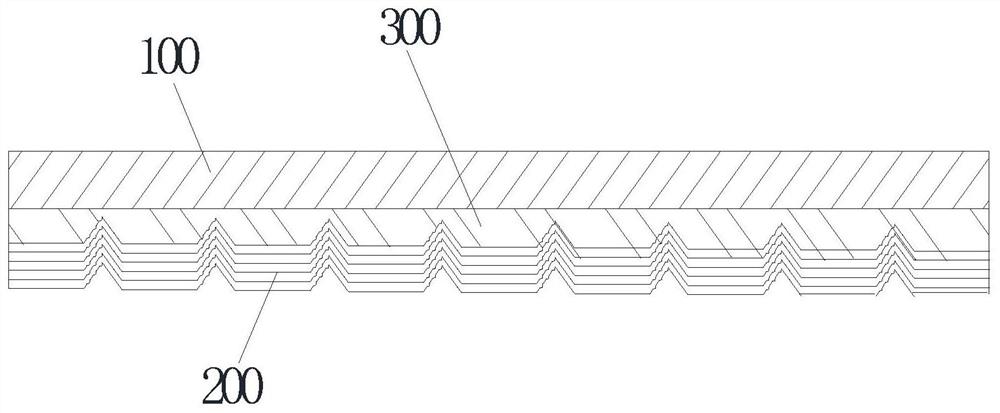

[0041] This embodiment discloses an antibacterial plastic packaging bag for diapers, comprising a plastic film layer 100 and an antibacterial nonwoven layer 200, wherein the antibacterial nonwoven layer 200 includes the following materials in parts by weight:

[0042]

[0043]

[0044] The antibacterial non-woven fabric layer is provided with a stretchable structure along its length direction to cooperate with the deformation of the plastic film layer by external force.

[0045] In this embodiment, the antibacterial nonwoven layer is bonded on the surface of the plastic film layer by acrylic resin; wherein, the thickness of BOPP is 35 μm, the thickness of acrylic resin is 10 μm, and the thickness of the antibacterial nonwoven layer is 20 μm, wherein the nonwoven The protruding part of the V-shaped fiber protrudes into the acrylic resin layer 300 .

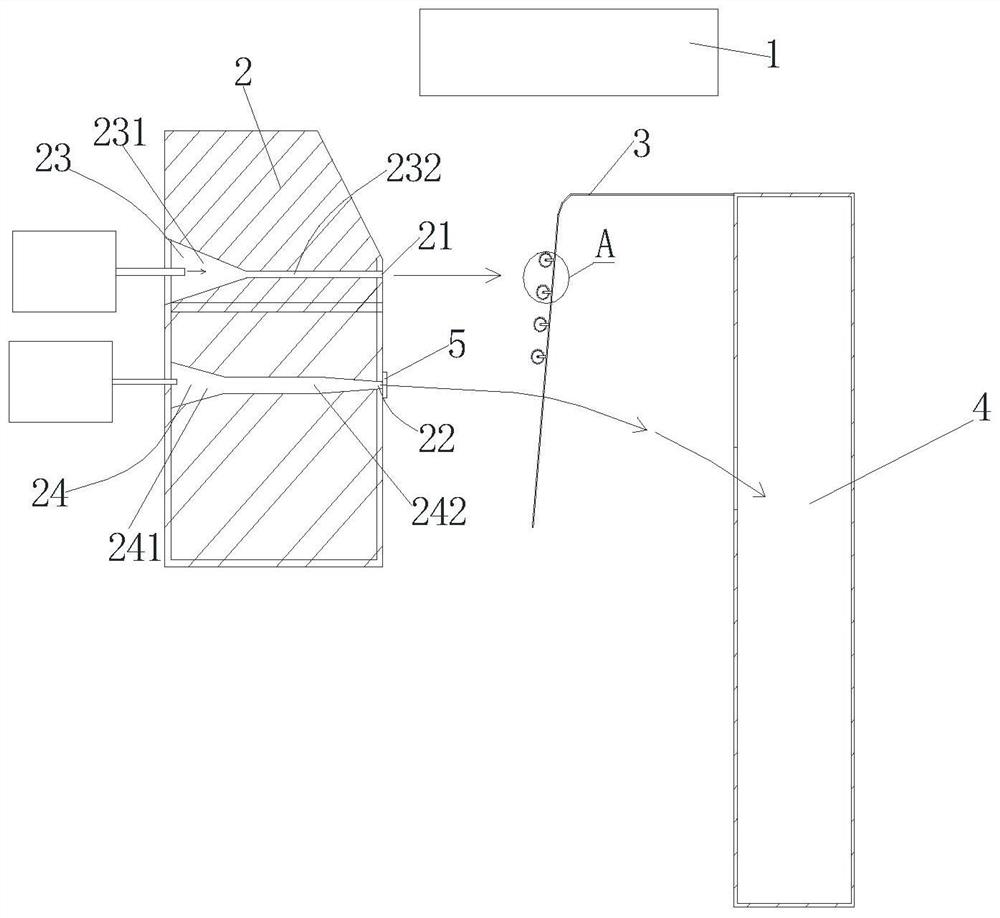

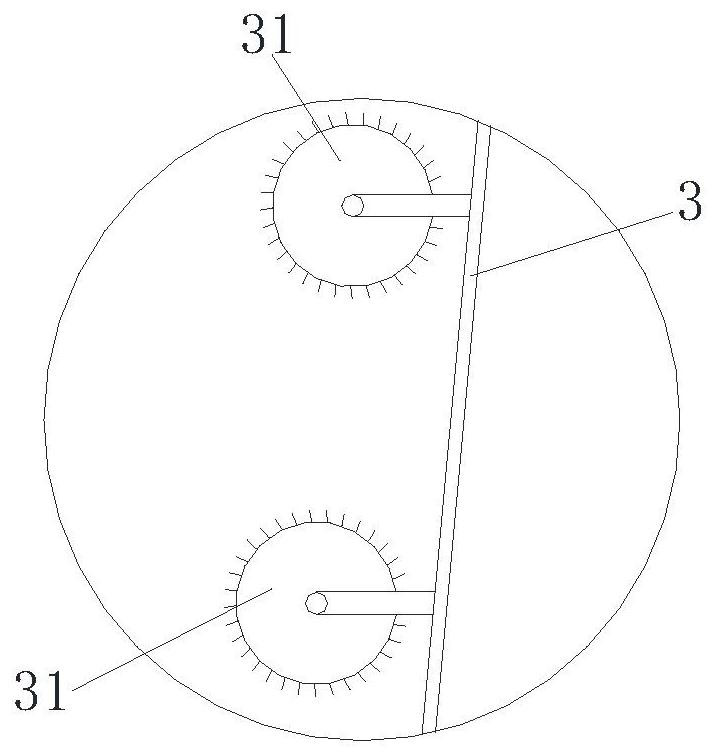

[0046] Antibacterial non-woven fabric is prepared through the following steps in the present embodiment:

[0047] Step 1, ...

Embodiment 2

[0065] The main difference between this embodiment and embodiment 1 is:

[0066] In the present embodiment, the antibacterial non-woven fabric layer 200 comprises the following materials in parts by weight:

[0067]

Embodiment 3

[0069] The main difference between this embodiment and embodiment 1 is:

[0070] In the present embodiment, the antibacterial non-woven fabric layer 200 comprises the following materials in parts by weight:

[0071]

[0072] The comparative example adopts the same BOPP film as in Example 1.

[0073] The moisture evaporative transmission rate and tensile strength of the packaging bags prepared in Examples 1 to 3 are shown in Table 1.

[0074] Table 1 embodiment 1 to 3 gained packaging bag and the performance contrast of comparative example

[0075] project comparative example Example 1 Example 2 Example 3 Moisture evaporation transmission rate (g / 100in 2 *day)

0.32 0.19 0.17 0.20 Tensile strength (MPa) 93 87 89 86 elongation at break 201% 176% 182% 177%

[0076] The water vapor transmission rate in Table 1 refers to the percentage of water reaching the other side of the film layer through adsorption, dissolution, and dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com