Method for removing iron ions on titanium surface before heat treatment of titanium clad steel plate device

A composite steel plate and iron ion technology, which is applied in the coating process of metal materials, etc., can solve the problems of secondary pollution, large manpower consumption, time-consuming material resources, and difficult dust removal, so as to avoid erosion and damage and reduce enterprise costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

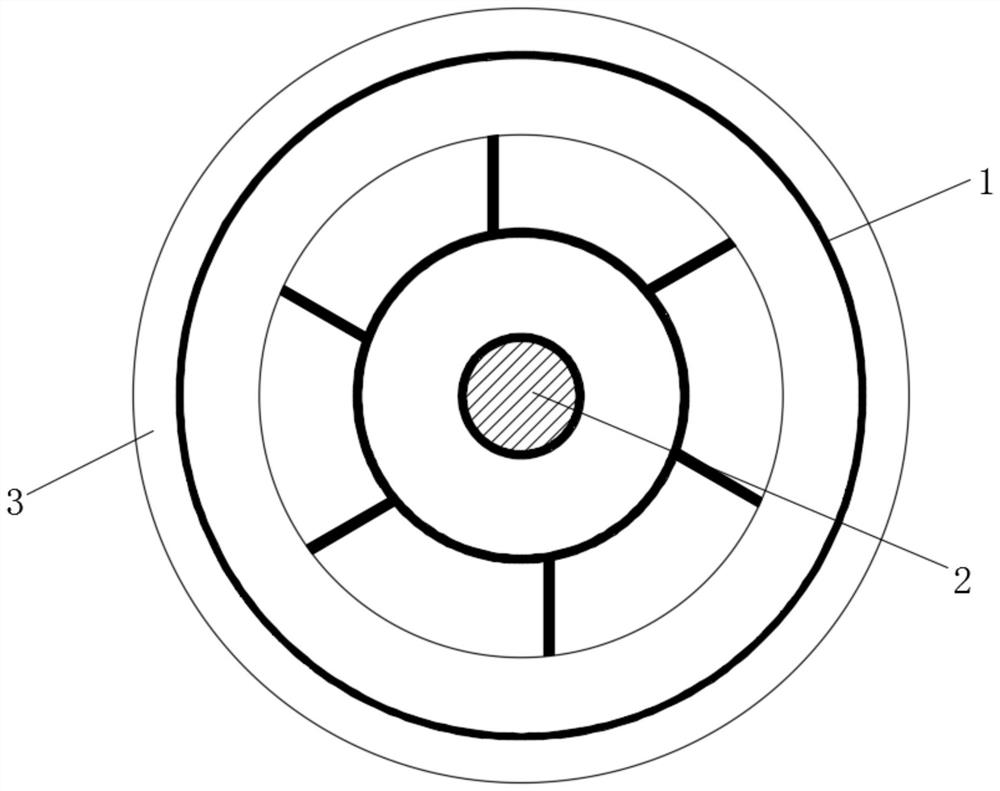

[0031] See attached figure 1 As shown, a method for removing iron ions on the titanium surface before the heat treatment of a titanium clad steel plate equipment in this embodiment includes the following steps:

[0032] S1: Preparations before pickling the titanium clad steel plate equipment body:

[0033] 1) Grind and smooth the inner side of the longitudinal girth weld on the titanium composite steel plate equipment body, and remove the iron ash dust after grinding, and clean the surface;

[0034] 2) Remove the heat-resistant tapes on both sides of the longitudinal girth weld, grind away the solder spots splashed on the titanium-clad steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com