Method for preparing silicon carbide crystal by taking single gas as source gas

A silicon carbide and source gas technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as high cracking temperature, low gas stability and easy spontaneous combustion, and achieve the effect of risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, methylsilane is selected as the source gas, and helium is used as the carrier gas.

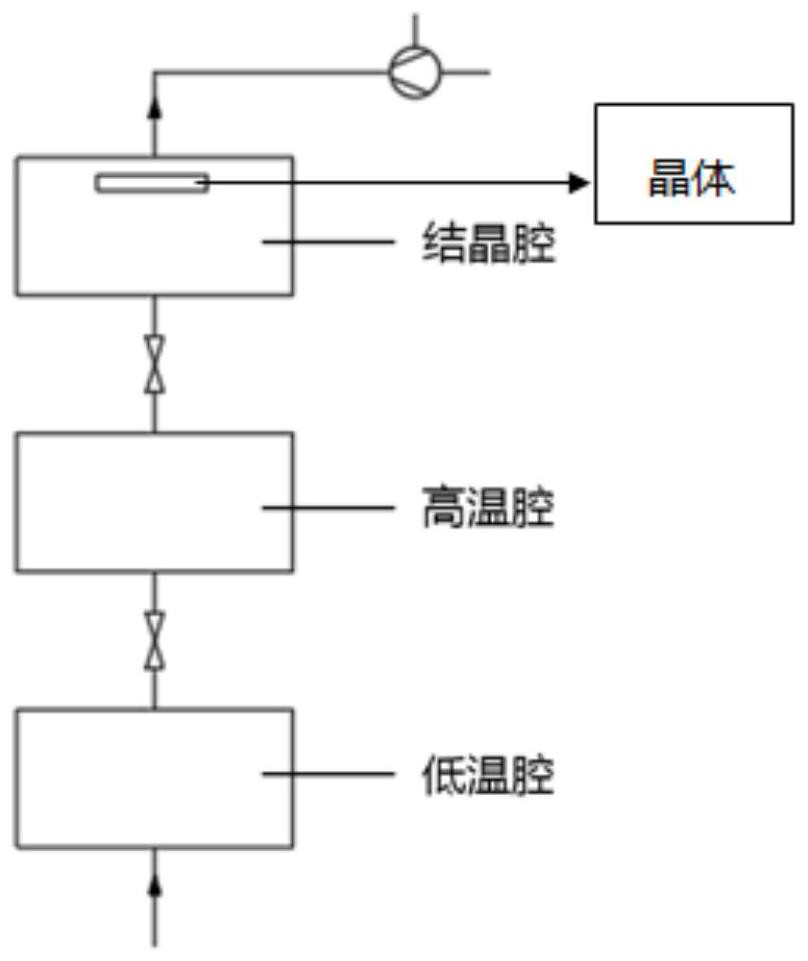

[0032] Place the prepared seed crystal, crucible and heat preservation material in the furnace cavity. Start the crystal growth program, wash the furnace, check for leaks, and repeat 2 times. Pass methylsilane into the low-temperature chamber in the furnace, set the flow rate to 1slm, and adjust the flow rate of He to 6slm. Open the pressure control butterfly valve to keep the pressure in the equipment at 100mbar. By ramping up the temperature, the temperature of the low-temperature chamber is 550°C, the temperature of the high-temperature chamber is 2250°C, and the temperature of the crystallization chamber is 2200°C. By controlling the reaction gas valve, adjust the flow rate of the reaction gas to 100 sccm. During the crystal growth process, maintain this parameter for crystal growth for 50h. After the crystal growth program is completed, start the cooling pro...

Embodiment 2

[0034] In this embodiment, trimethylchlorosilane is selected as the source gas, and argon is used as the carrier gas.

[0035]Place the prepared seed crystal, crucible and heat preservation material in the furnace cavity. Start the crystal growth program, wash the furnace, check for leaks, and repeat 2 times. Pass trimethylchlorosilane into the low-temperature chamber in the furnace, set the flow rate to 10slm, and adjust the flow rate of Ar to 10slm. Open the pressure control butterfly valve to keep the pressure in the equipment at 500mbar. The temperature of the low temperature chamber is 620°C, the temperature of the high temperature chamber is 2450°C, and the temperature of the crystallization chamber is 2100°C. By controlling the reaction gas valve, adjust the flow rate of the reaction gas to 500 sccm. During the crystal growth process, maintain this parameter for crystal growth for 20h. After the crystal growth program is completed, start the cooling program, inflate...

Embodiment 3

[0037] In this embodiment, hexamethyldisilane is selected as the source gas, and hydrogen and argon are used as the carrier gas.

[0038] Place the prepared seed crystal, crucible and heat preservation material in the furnace cavity. Start the crystal growth program, wash the furnace, check for leaks, and repeat 3 times. Pass hexamethyldisilane into the low-temperature chamber in the furnace, set the flow rate to 35 slm, and adjust the flow rate of Ar to 50 slm. Open the pressure control butterfly valve to keep the pressure in the equipment at 1000mbar. The temperature of the low temperature chamber is 1000°C, the temperature of the high temperature chamber is 2300°C, and the temperature of the crystallization chamber is 2000°C. By controlling the reaction gas valve, adjust the flow rate of the reaction gas to 10 sccm. During the crystal growth process, maintain this parameter for crystal growth for 35h. After the crystal growth program is completed, start the cooling prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com