Condensation heat recovery system and method

A heat recovery and cold water technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as effective treatment and impact on environmental quality, and achieve the effects of increasing absorption rate, increasing contact area, and improving heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

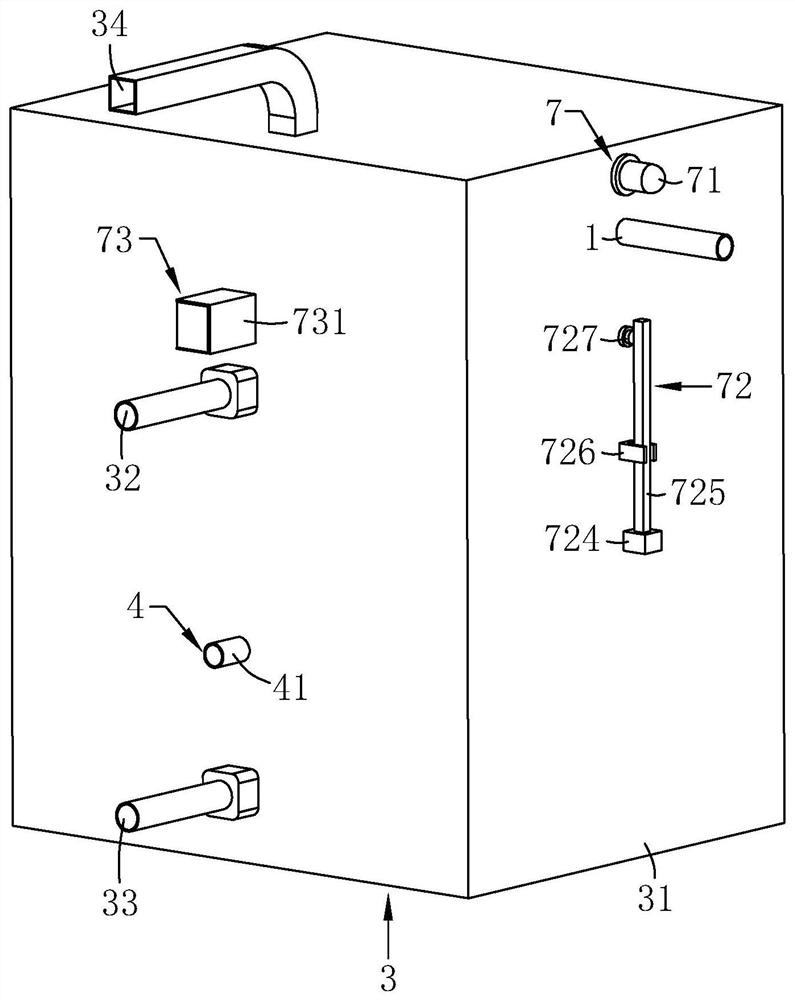

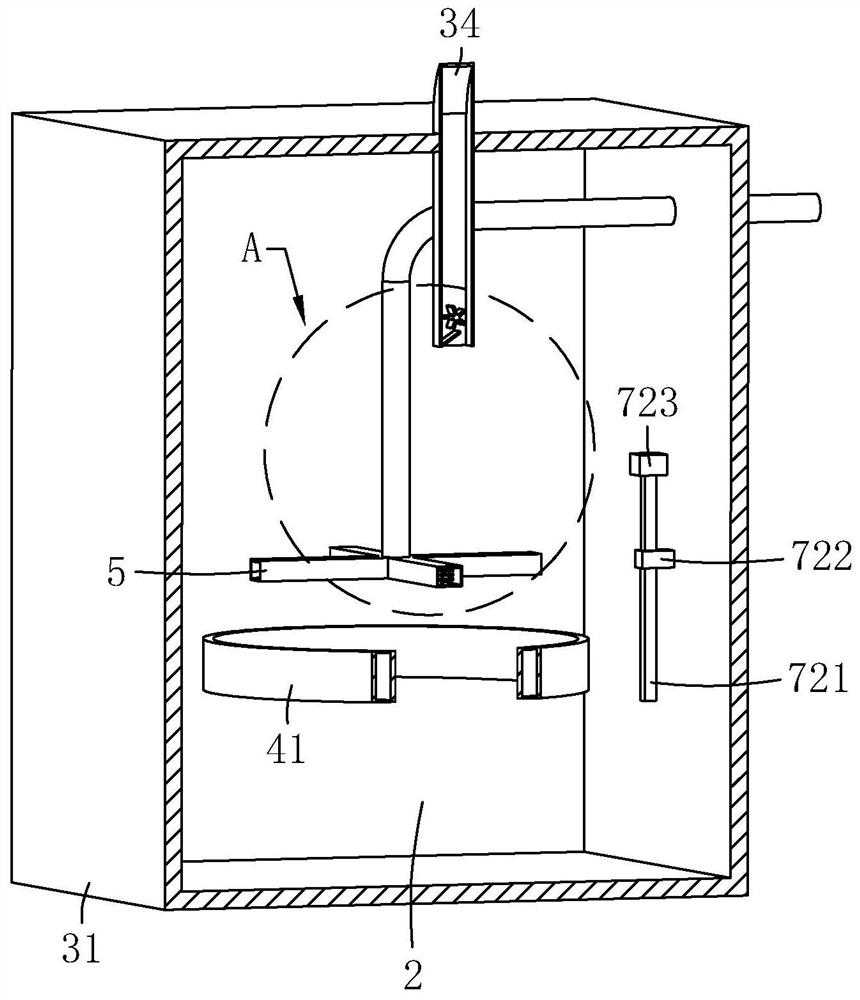

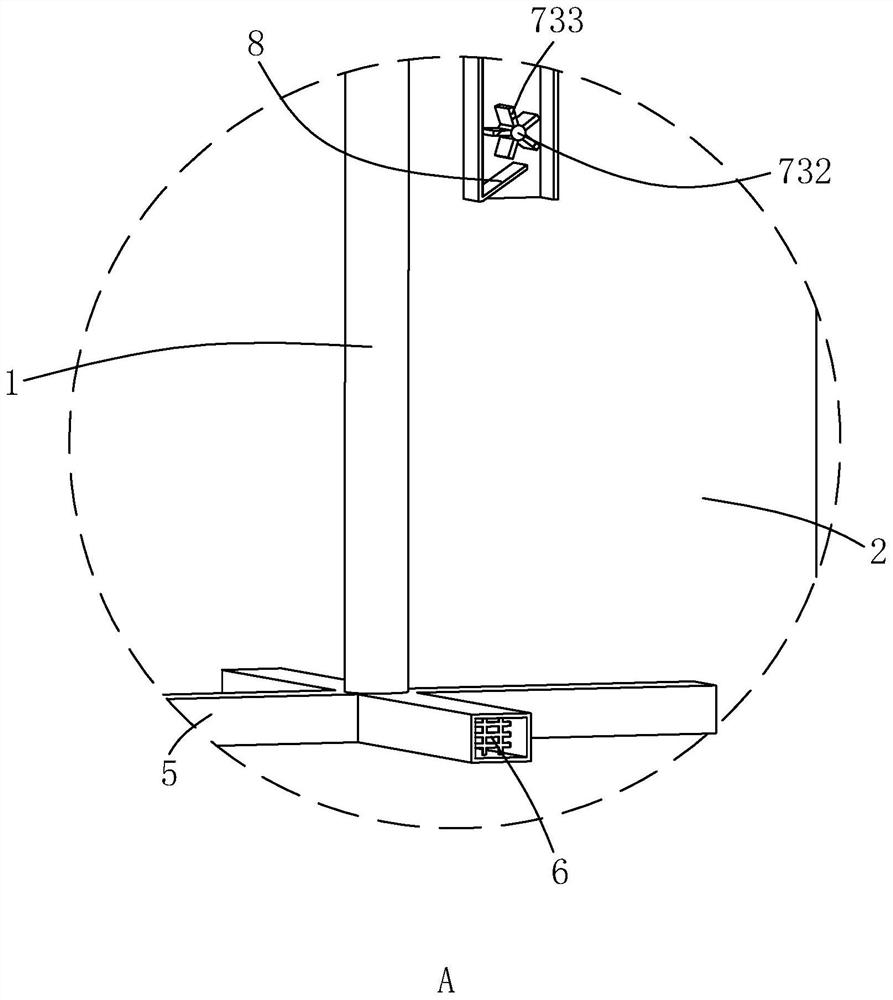

[0062] The following is attached Figure 1-3 The application is described in further detail.

[0063] In the first aspect, the embodiment of the present application discloses a condensation heat recovery system.

[0064] refer to figure 1 and figure 2 , a condensation heat recovery system comprising an air intake pipe 1, a heat exchange fluid 2, a housing mechanism 3 for accommodating the heat exchange fluid 2, a heat recovery mechanism 4, and a prompt mechanism 7, one end of the air intake pipe 1 is connected to the outlet end of a constant temperature and humidity machine Through flange connection, the other end of the intake pipe 1 is immersed in the heat exchange liquid 2; the heat recovery mechanism 4 is connected with the accommodation mechanism 3, and the heat-absorbing part of the heat recovery mechanism 4 is immersed in the heat exchange fluid 2, and the prompting mechanism 7 and the accommodation mechanism 3 connection; the heat exchange fluid 2 in this applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com