Preparation method of water-based ceramic slurry for coating and battery diaphragm

A ceramic slurry, water-based technology, applied in the direction of non-aqueous electrolyte batteries, lithium batteries, battery pack parts, etc., to achieve the effect of preventing more fractures, convenient adjustment, and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

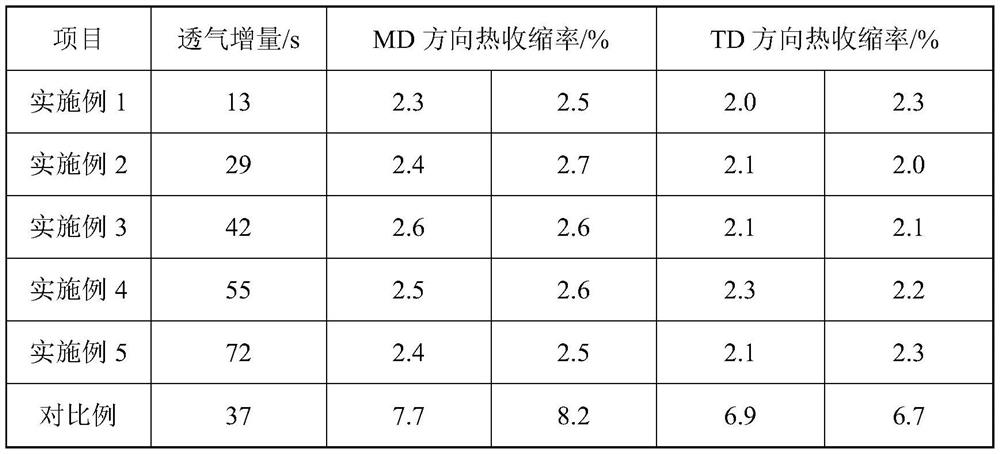

Embodiment 1

[0038] S1: Dissolve 83 parts of ceramic powder in 93 parts of deionized water, stir evenly, add 0.1245 parts of CMC and 0.1245 parts of dispersant to it in turn, and stir evenly to obtain the first mixture;

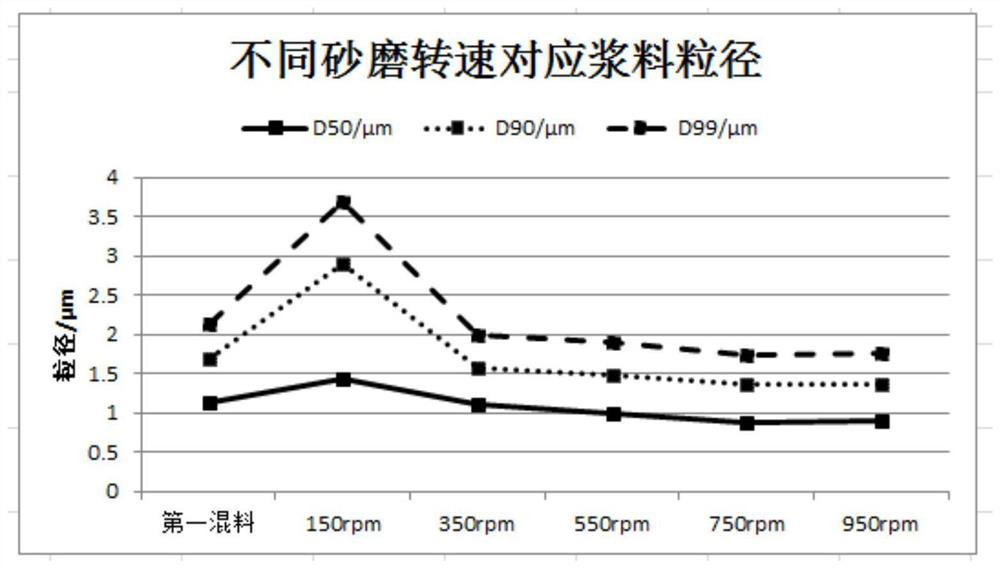

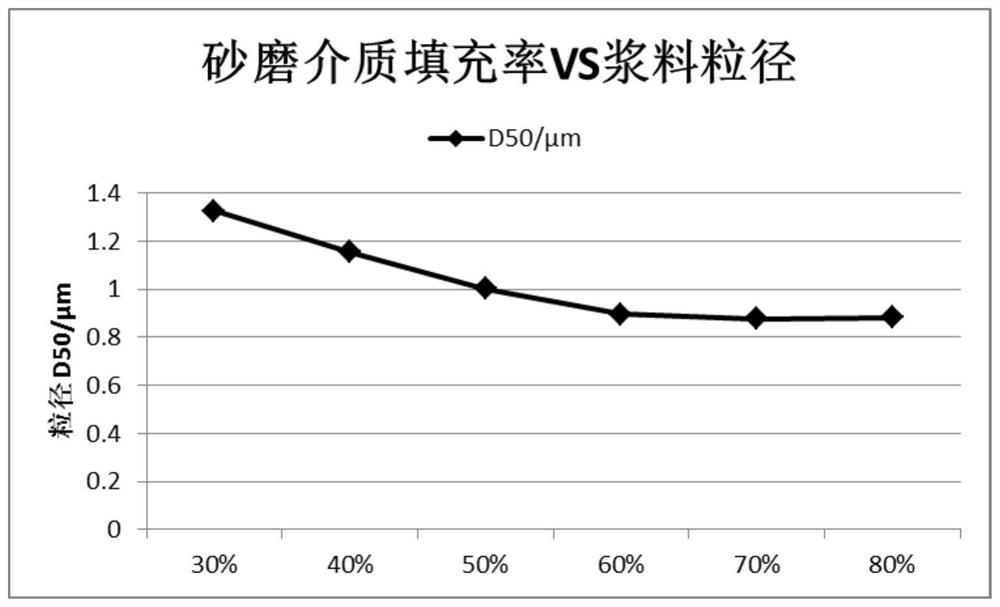

[0039] S2: After adding the first mixed material into the sand mill for sand grinding, add 0.54 parts of CMC again and stir evenly to obtain the second mixed material; the sand mill flow rate is 1200L / h, the sand mill speed is 750rpm, and the sand mill medium is oxidized Zirconia beads, the filling amount is 60% of the sanding chamber, and the size of the zirconia beads is 0.6-0.8mm.

[0040] S3: Add 0.0295 parts of polyacrylate adhesive and 0.57 parts of wetting agent to the second mixture in turn, and stir evenly to obtain a third mixture;

[0041] S4: performing foreign matter filtration and magnetic separation on the third mixed material to obtain ceramic slurry.

[0042] S5: The ceramic slurry is uniformly coated on one side surface of a PE microporous diaphragm wit...

Embodiment 2

[0044] S1: Dissolve 83 parts of ceramic powder in 93 parts of deionized water, stir evenly, add 0.1245 parts of thickener and 0.1245 parts of dispersant to it in turn, and stir evenly to obtain the first mixture;

[0045] S2: After adding the first mixed material into the sand mill for sand grinding, add 0.54 parts of CMC again and stir evenly to obtain the second mixed material; the sand mill flow rate is 1200L / h, the sand mill speed is 750rpm, and the sand mill medium is oxidized Zirconia beads, the filling amount is 60% of the sanding chamber, and the size of the zirconia beads is 0.6-0.8mm.

[0046] S3: Add 0.0376 parts of polyacrylate adhesive and 0.57 parts of wetting agent to the second mixture in turn, and stir evenly to obtain a third mixture;

[0047] S4: performing foreign matter filtration and magnetic separation on the third mixed material to obtain ceramic slurry.

[0048] S5: The ceramic slurry is uniformly coated on one side surface of a PE microporous diaphragm...

Embodiment 3

[0050] S1: Dissolve 83 parts of ceramic powder in 93 parts of deionized water, stir evenly, add 0.1245 parts of CMC and 0.1245 parts of dispersant to it in turn, and stir evenly to obtain the first mixture;

[0051] S2: After adding the first mixed material into the sand mill for sand grinding, add 0.54 parts of CMC again and stir evenly to obtain the second mixed material; the sand mill flow rate is 1200L / h, the sand mill speed is 750rpm, and the sand mill medium is oxidized Zirconia beads, the filling amount is 60% of the sanding chamber, and the size of the zirconia beads is 0.6-0.8mm.

[0052] S3: Add 0.054 parts of polyacrylate adhesive and 0.57 parts of wetting agent to the second mixture in turn, and stir evenly to obtain a third mixture;

[0053] S4: performing foreign matter filtration and magnetic separation on the third mixed material to obtain ceramic slurry.

[0054] S5: The ceramic slurry is uniformly coated on one side surface of a PE microporous diaphragm with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com