Bidirectional silicon-controlled rectifier

A silicon controlled rectifier, N-type technology, applied in the direction of semiconductor devices, electric solid state devices, electrical components, etc., to achieve the effects of low parasitic capacitance, optimized device performance, and low trigger voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

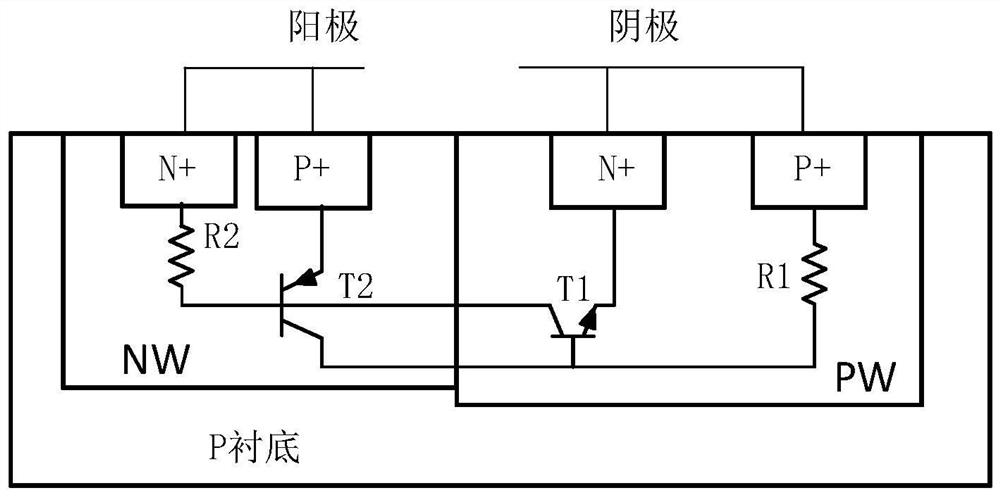

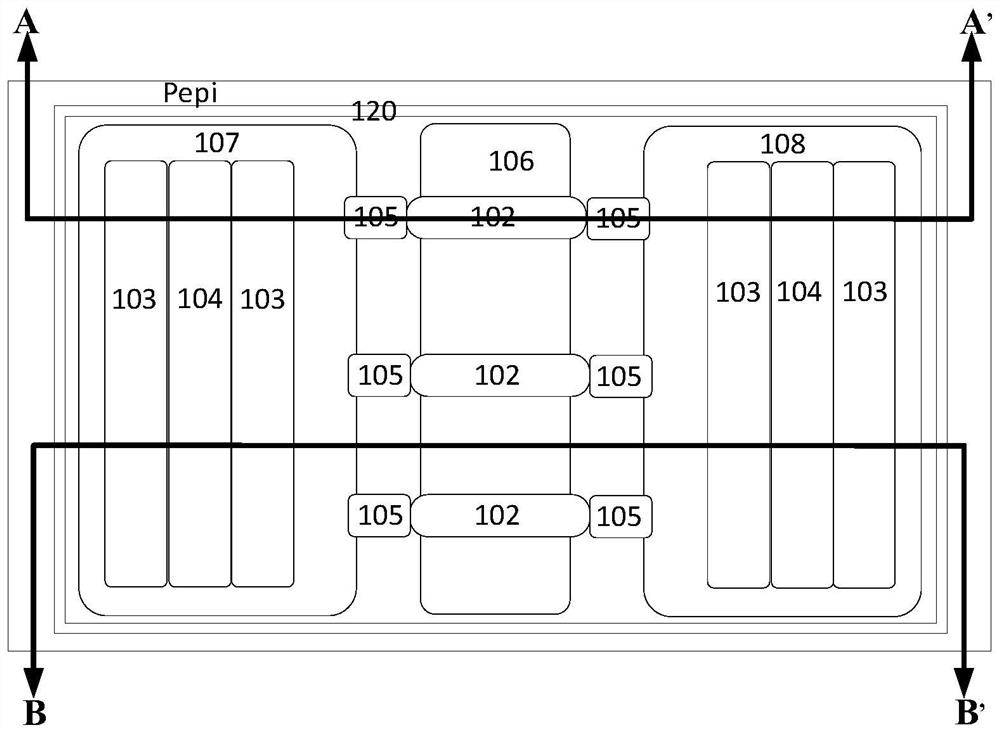

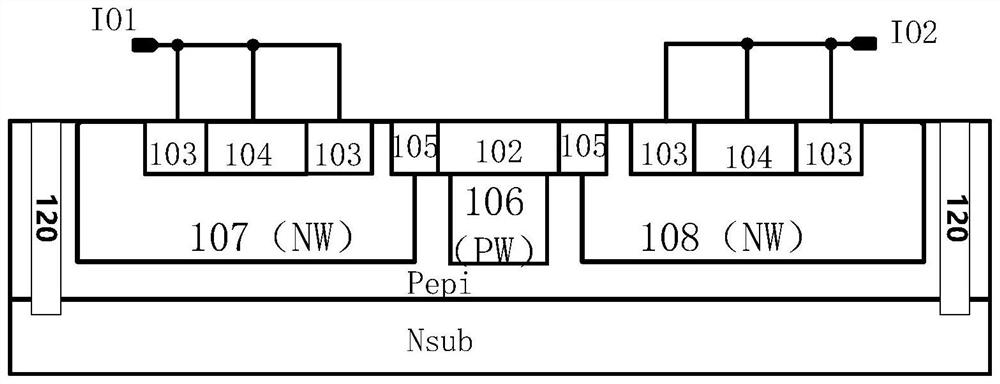

[0048] Such as Figure 2 ~ Figure 4 , the bidirectional silicon-controlled rectifier proposed in the present invention includes a substrate epitaxial crystal, specifically, the substrate epitaxial crystal is an N-type conductive substrate and a P-type conductive epitaxy; it also includes a silicon-controlled rectifier region formed in the substrate epitaxial crystal, The silicon controlled rectifier region includes a first N-type well region 107 , a second N-type well region 108 , and a first P-type well region 106 . The first P-type well region 106 is located between the first N-type well region 107 and the second N-type well region 108; the first N-type well region 107 includes an N-type heavily doped region 103 and a P-type heavily doped region 104 , the N-type heavily doped region 103 and the P-type heavily doped region 104 are connected through metal and connected to the input port IO1; the second N-type well region 108 includes the N-type heavily doped region 103 and the...

Embodiment 2

[0055] Such as Figure 5 As shown, the difference from Implementation Example 1 is that the trigger region process is different. The N-type doped region 105 is no longer located on the surface, but symmetrically located under the P-type doped region 102. This solution can be realized by using a larger implant energy . The advantage is that the internal area is fully utilized, the surface area of the device is reduced, and the influence of overlay deviation can be avoided in small-scale processes. The N-type doped region 105 partially overlaps the N-type well region 107 , but the N-type doped region 105 in the N-type well region 107 and the N-type well region 108 cannot connect across the P-type well region 106 . In the second implementation example, the trigger voltage of the bidirectional silicon controlled rectifier is still controlled by the diode formed by the N-type doped region 105 and the P-type doped region 102 in the trigger region. Preferably, the P-type doped reg...

Embodiment 3

[0057] Such as Figure 6 As shown, the difference from Implementation Example 1 is that it is fabricated on a P-type substrate and an N-type epitaxial crystal, and the corresponding silicon-controlled rectifier area and trigger area are changed:

[0058] The silicon controlled rectifier region includes a first P-type well region 109 , a second P-type well region 110 , and a first N-type well region 111 . The first N-type well region 111 is located between the first P-type well region 109 and the second P-type well region 110; the first P-type well region 109 includes an N-type heavily doped region 103 and a P-type heavily doped region 104 , the N-type heavily doped region 103 and the P-type heavily doped region 104 are connected through metal and connected to the input port IO1; the second P-type well region 110 includes the N-type heavily doped region 103 and the P-type heavily doped region 104, the N-type heavily doped region 103 and the P-type heavily doped region 104 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com