Preparation method and application of self-assembled core-shell structure positive electrode material

A core-shell structure and cathode material technology, applied in the field of nanomaterials, can solve the problems of overheating of cathode materials, material decomposition out of control, battery fire, etc., to achieve the effects of sufficient reaction, high yield and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

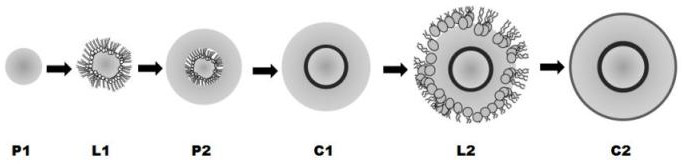

[0068] A method for preparing a self-assembled core-shell structure positive electrode material, comprising the steps of:

[0069] (1) Preparation of doped nickel-cobalt-manganese core precursor P1:

[0070] Add nickel salt, cobalt salt, manganese salt and other metal salts into the aqueous solution, pass in protective gas, then stir and adjust the pH value of the solution, filter and dry the solution after the reaction, and obtain the doped nickel-cobalt-manganese core precursor P1 ;

[0071] (2) Preparation of P1 surface-modified self-assembled monolayer core precursor L1:

[0072] Add the doped nickel-cobalt-manganese core precursor P1 obtained in step (1) into the mixed solution, add polar amphiphilic molecules into the mixed solution, then stir and adjust the pH value of the solution, and filter and dry the solution after the reaction , and sieve to obtain the P1 surface-modified self-installed single-layer membrane core precursor L1;

[0073] (3) Preparation of doped ...

Embodiment 1

[0082] A method for preparing a self-assembled core-shell structure positive electrode material, comprising the steps of:

[0083] (1) Preparation of doped nickel-cobalt-manganese core precursor P1:

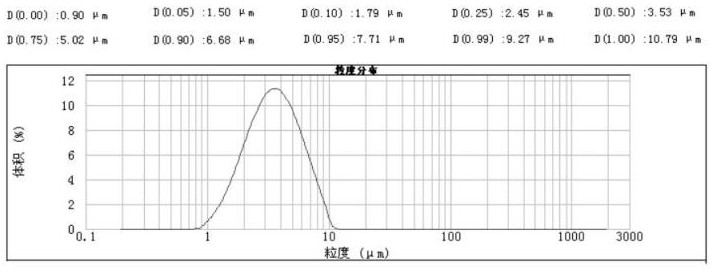

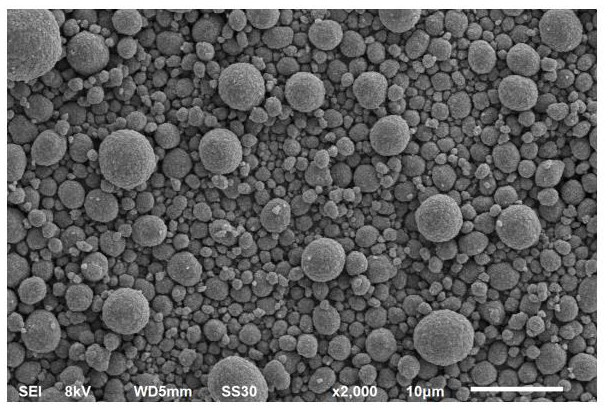

[0084] Nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate prepare mixed salt solution (1.5mol / L) in molar ratio 65:7:18:0.03, mix solution with 4mol / L NaOH solution and the ammoniacal solution of certain concentration (12wt% ) into the reactor in parallel flow, filled with nitrogen in the reactor, controlling the temperature in the reactor to be 42°C, controlling the pH value in the reactor at 10.0-13.0, starting the stirring device in the reactor, the stirring device The stirring speed is 1000rpm / min, and the reaction product obtained by the reaction is aged for 5 hours, press-filtered, washed, and dried to obtain the product P1 with a D50 of 3.53 microns, and the particle size distribution of P1 is as follows figure 2 As shown, the SEM image of P1 is as ...

Embodiment 2

[0101] The difference from Example 1 is: in the step (2), the colorless liquid hydrophilic ionic liquid is 1-butyl-3-methylimidazole dinitrile amine salt (C 10 h 15 N 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com