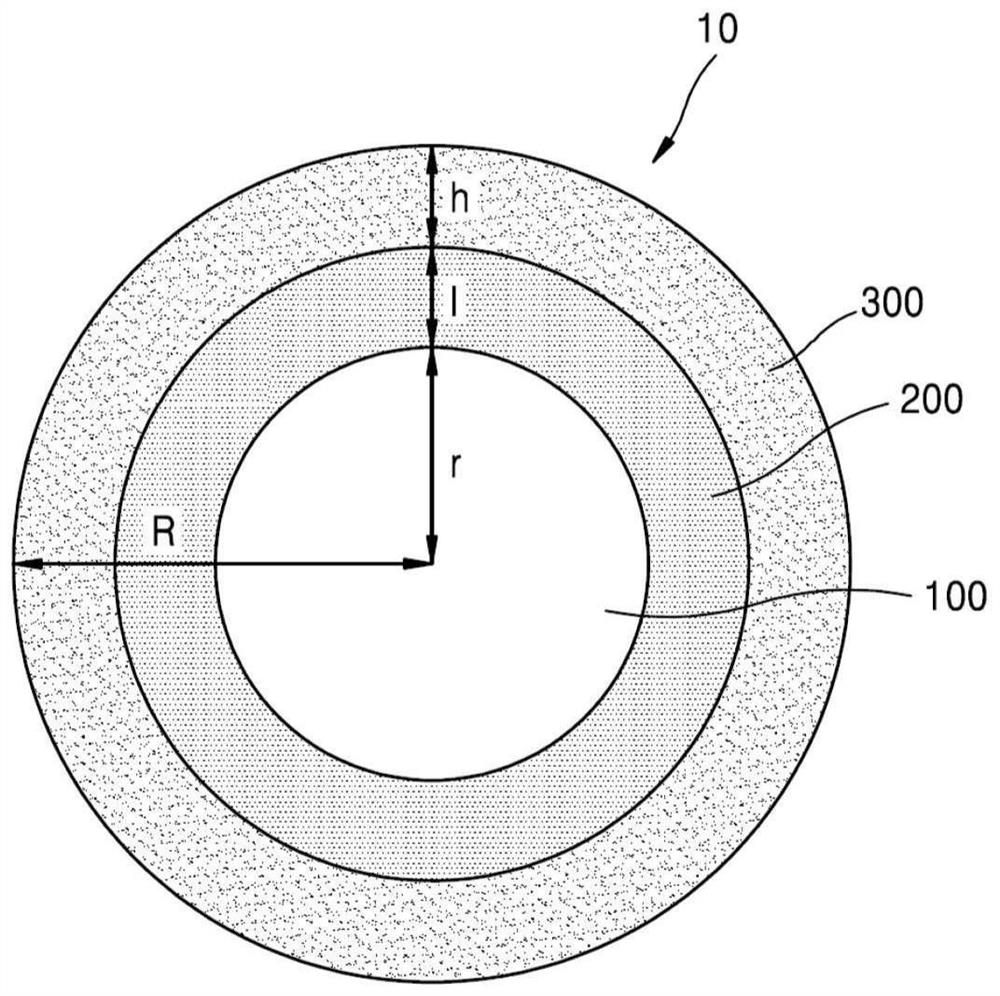

Semiconductor nanoparticles, color conversion member including same, and electronic device

A nanoparticle and electronic device technology, applied in the manufacture of semiconductor devices, organic semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of low light efficiency and achieve high blue light absorption rate, excellent light efficiency, and high color purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

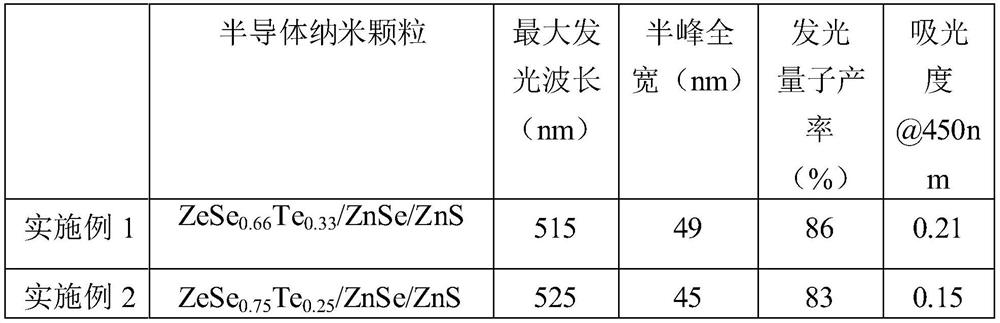

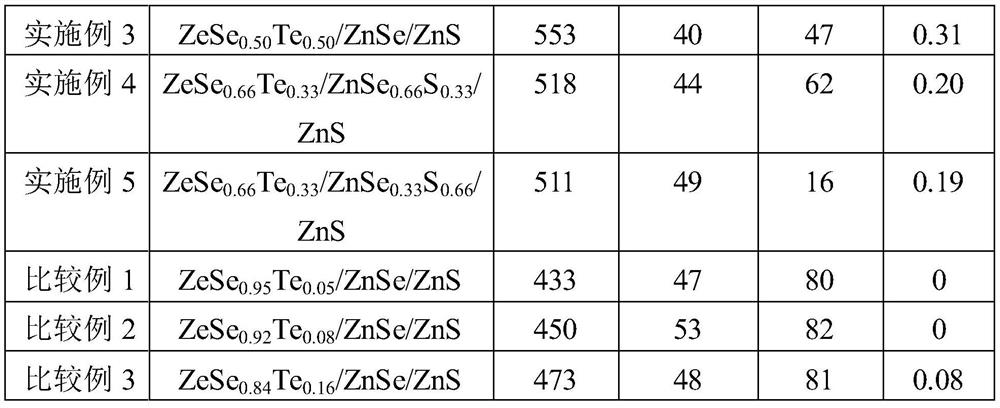

[0087] Example 1: ZeSe 0.66 Te 0.33 Synthesis of / ZnSe / ZnS Semiconductor Nanoparticles

[0088] 0.6 mmol of zinc oleate (Zinc Oleate) and 10 mL of 1-octadecene (1-octadecene) were added to the three-necked flask, and a vacuum state was maintained at 110° C. for 1 hour. Then, after releasing the vacuum and filling with an inert gas, the temperature was raised to 230°C. 0.2 mmol of diphenylphosphine selenide was added at 230° C., and then 0.1 mmol of trioctylphosphine telluride was added and reacted for 30 minutes, after which the temperature was raised to 300° C. and reacted for 15 minutes.

[0089] Next, 1 mmol of zinc oleate (Zinc Oleate) and 1 mmol of trioctylphosphine selenide (trioctylphosphine selenide) were added, followed by a reaction for 1 hour to form a zinc selenide (Zinc selenide) shell.

[0090] Thereafter, 2 mmol of zinc oleate (Zinc Oleate) and 2 mmol of trioctylphosphinesulfide (trioctylphosphinesulfide) were added, followed by a reaction for 1 hour to fo...

Embodiment 2

[0091] Example 2: ZeSe 0.75 Te 0.25 Synthesis of / ZnSe / ZnS Semiconductor Nanoparticles

[0092] 0.6 mmol of zinc oleate (Zinc Oleate) and 10 mL of 1-octadecene (1-octadecene) were added to the three-necked flask, and a vacuum state was maintained at 110° C. for 1 hour. Then, after releasing the vacuum and filling with an inert gas, the temperature was raised to 230°C. 0.225 mmol of diphenylphosphine selenide was added at 230°C, and then 0.075 mmol of trioctylphosphine telluride was added and reacted for 30 minutes, then the temperature was raised to 300°C and reacted for 15 minutes. In the subsequent process, the zinc selenide (Zinc selenide) shell and the zinc sulfide (Zinc Sulfide) shell were sequentially formed by the same method as in Example 1, thereby obtaining the semiconductor nanoparticles of Example 2.

Embodiment 3

[0093] Example 3: ZeSe 0.5 Te 0.5 Synthesis of / ZnSe / ZnS Semiconductor Nanoparticles

[0094] 0.6 mmol of zinc oleate (Zinc Oleate) and 10 mL of 1-octadecene (1-octadecene) were added to the three-necked flask, and a vacuum state was maintained at 110° C. for 1 hour. Then, after releasing the vacuum and filling with an inert gas, the temperature was raised to 230°C. 0.15 mmol of diphenylphosphine selenide was added at 230° C., and then 0.15 mmol of trioctylphosphine telluride was added and reacted for 30 minutes, after which the temperature was raised to 300° C. and reacted for 15 minutes. In the subsequent process, the zinc selenide (Zinc selenide) shell and the zinc sulfide (Zinc Sulfide) shell were sequentially formed by the same method as in Example 1, thereby obtaining the semiconductor nanoparticles of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com