High-capacity and high-cycle lithium battery negative electrode material and preparation method thereof

A negative electrode material and lithium battery technology, applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve the problems of poor cycle performance of negative electrode materials, and achieve high conductivity, stable performance, and tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a high-capacity and high-cycle lithium battery negative electrode material, comprising the steps of:

[0042] (1) Mixing: GeO 2 The powder and the Si powder with a particle size of 7 μm are mixed according to the molar ratio of 1:3, and the planetary ball is milled for 3 hours to obtain the mixed powder SGO3; the particle size D10 of the mixed powder SGO3 is 2.13 μm, D50 is 31.58 μm, and the BET ratio Surface area is 3.85m 2 / g;

[0043] (2) Heat treatment: The mixed powder obtained in step (1) was reacted at a high temperature of 750°C for 3 hours under a nitrogen atmosphere to prepare a high-capacity and high-cycle lithium battery anode material SG2.

[0044] The high-capacity and high-cycle lithium battery negative electrode material prepared above has a three-layer coating structure, including Si core, composite intermediate layer and GeO 2 The outer layer, the composite middle layer is Ge and SiO 2 of composite materials.

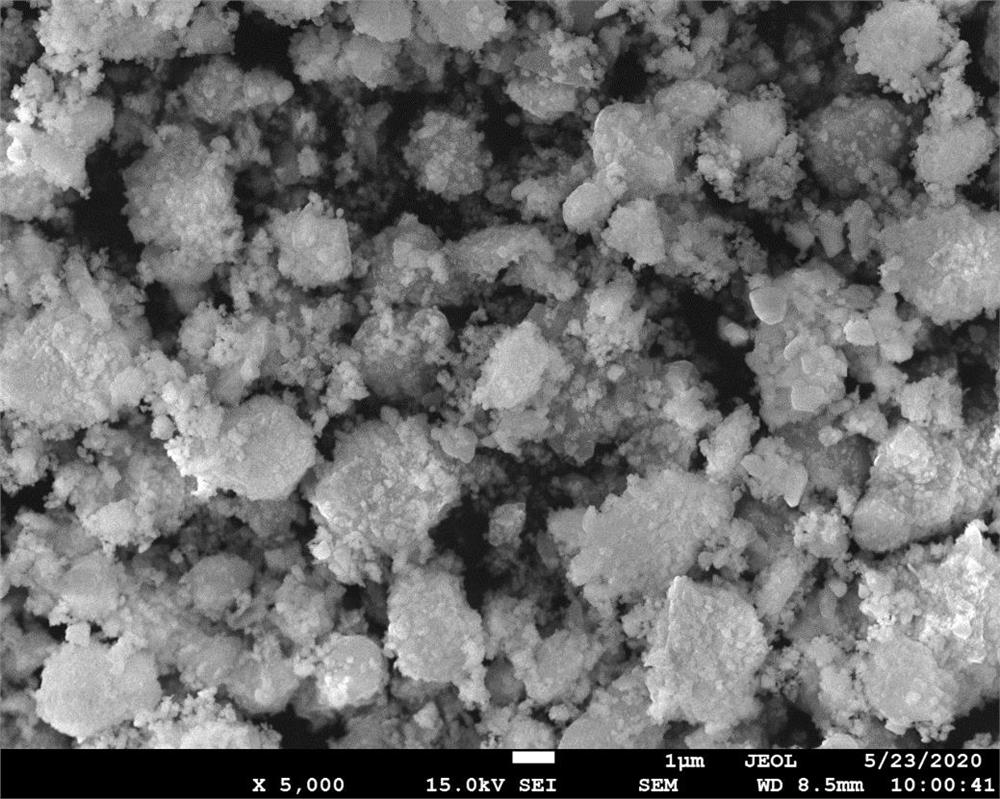

[0045] See a...

Embodiment 2

[0047] A preparation method of a high-capacity and high-cycle lithium battery negative electrode material, comprising the steps of:

[0048] (1) Mixing: GeO 2 The powder and the Si powder with a particle size of 7 μm are mixed according to the molar ratio of 1:5, and the planetary ball is milled for 3 hours to obtain the mixed powder SGO5; the particle size D10 of the mixed powder SGO5 is 1.41 μm, D50 is 29.58 μm, and the BET ratio Surface area is 7.06m 2 / g;

[0049] (2) Heat treatment: react the mixed powder obtained in step (1) under a nitrogen atmosphere at a high temperature of 750°C for 3 hours to prepare a high-capacity and high-cycle lithium battery anode material SG4.

[0050] The high-capacity and high-cycle lithium battery negative electrode material prepared above has a three-layer coating structure, including Si core, composite intermediate layer and GeO 2 The outer layer, the composite middle layer is Ge and SiO 2 of composite materials.

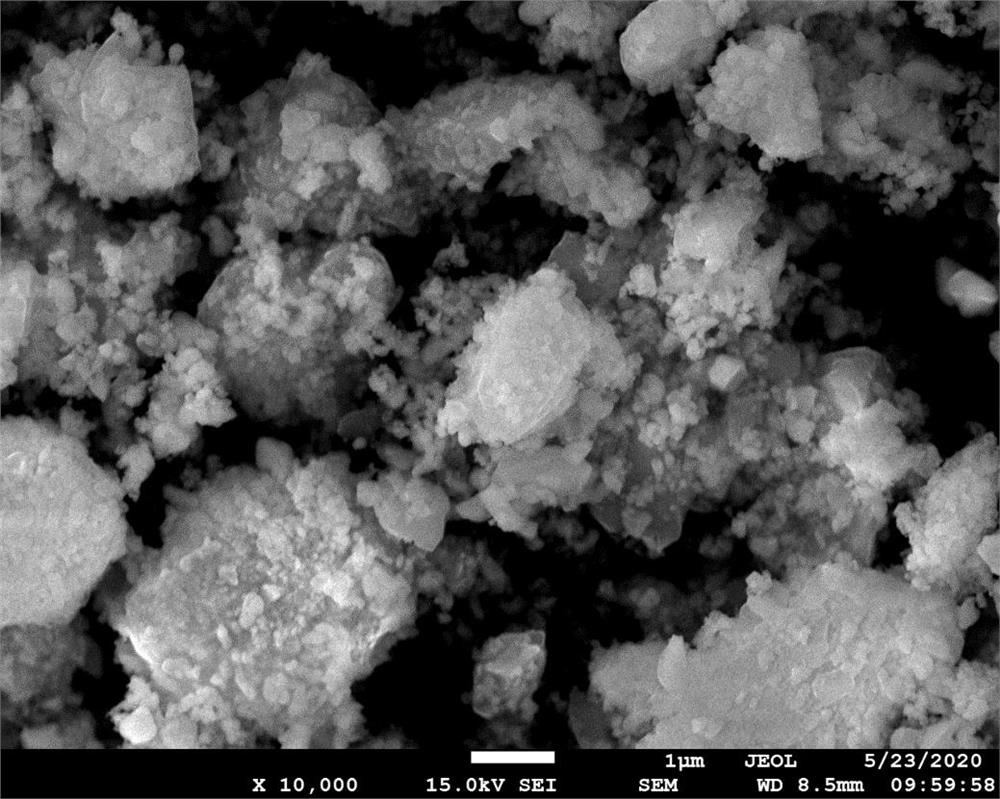

[0051] See attache...

Embodiment 3

[0053] A preparation method of a high-capacity and high-cycle lithium battery negative electrode material, comprising the steps of:

[0054] (1) Mixing: GeO 2 The powder and the Si powder with a particle size of 7 μm are mixed according to the molar ratio of 1:9, and the planetary ball is milled for 3 hours to obtain the mixed powder SGO9; the particle size D10 of the mixed powder SGO9 is 0.802 μm, D50 is 4.24 μm, and the BET ratio Surface area is 5.42m 2 / g;

[0055] (2) Heat treatment: The mixed powder obtained in step (1) was reacted at a high temperature of 750°C for 3 hours in a nitrogen atmosphere to prepare a high-capacity and high-cycle lithium battery anode material SG8.

[0056] The high-capacity and high-cycle lithium battery negative electrode material prepared above has a three-layer coating structure, including Si core, composite intermediate layer and GeO 2 The outer layer, the composite middle layer is Ge and SiO 2 of composite materials.

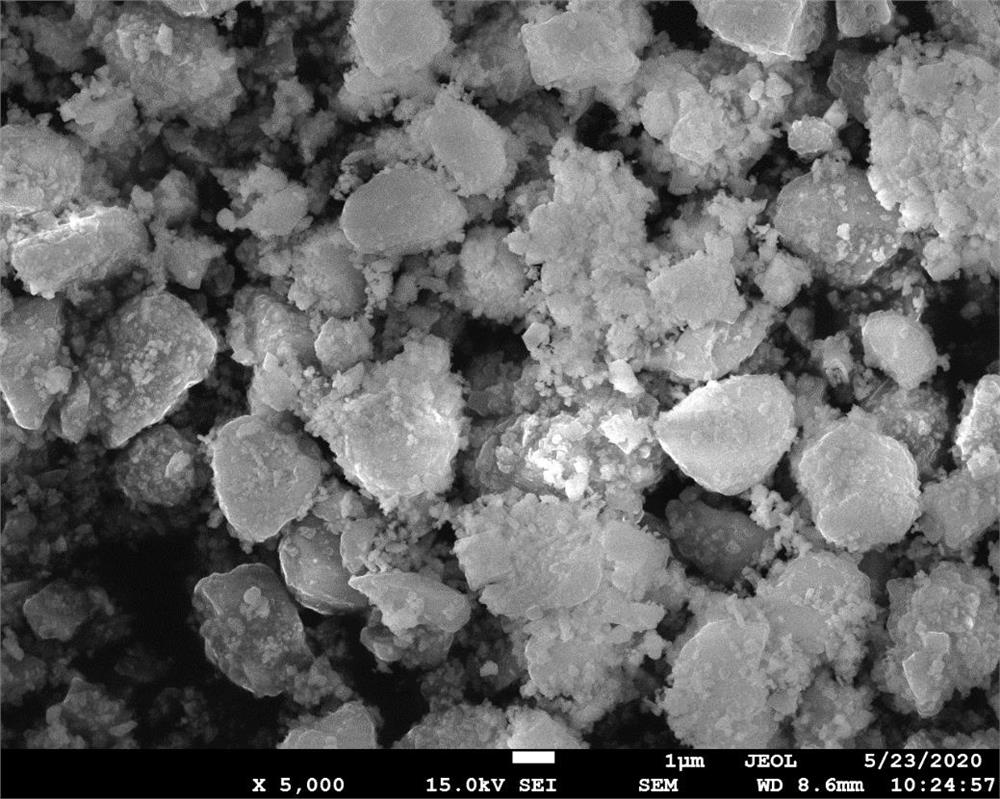

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com