Ferritic stainless steel sheet for current collectors for sulfide-based solid-state batteries, and method for manufacturing same

A stainless steel plate and solid battery technology, applied in secondary batteries, manufacturing tools, battery electrodes, etc., can solve the problems of battery performance, safety reduction, current collector corrosion, etc., and achieve the effect of excellent sulfuration resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

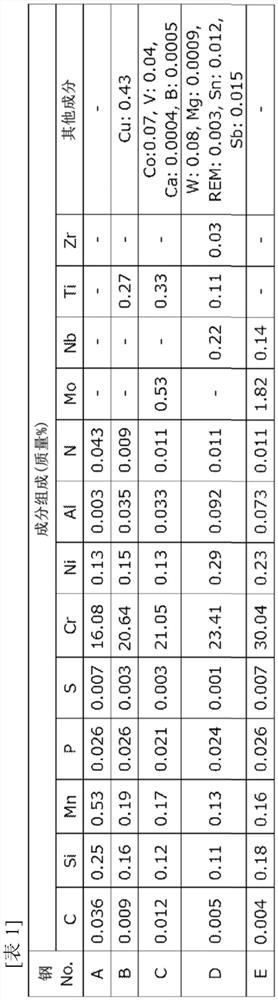

[0224] A stainless steel plate (raw material ferritic stainless steel plate) having a plate thickness of 10 μm having the composition described in Table 1 below (the balance being Fe and unavoidable impurities) was prepared.

[0225] With regard to the prepared stainless steel plates, under the conditions shown in the following Table 2, removal of the oxide film, etching treatment, immersion treatment or electrolytic treatment were performed (sample No. 4 to No. 9).

[0226] A sample that was not subjected to any of the above treatments was designated as sample No. 1, a sample that was only subjected to immersion treatment was designated as sample No. 2, and a sample that was subjected to only removal of the oxide film and etching treatment The sample was set as sample No.3. "-" in the production conditions in Table 2 below indicates that the treatment was not performed.

[0227] The current density in Table 2 below is a value obtained by dividing the current flowing between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com