Double-groove framing type photovoltaic and photo-thermal integrated assembly

A photovoltaic and photothermal technology, which is applied in the comprehensive application field of solar photovoltaic photothermal, can solve the problems that affect the power generation function and service life of photovoltaic cells, hidden cracks in cells, and large deformation of heat collecting substrates, etc., so as to improve the efficiency of photovoltaic power generation and heating efficiency, improve the utilization rate of heat energy, and facilitate the effect of heat conduction and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. structure, so it only shows the configuration related to the present invention, and it should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

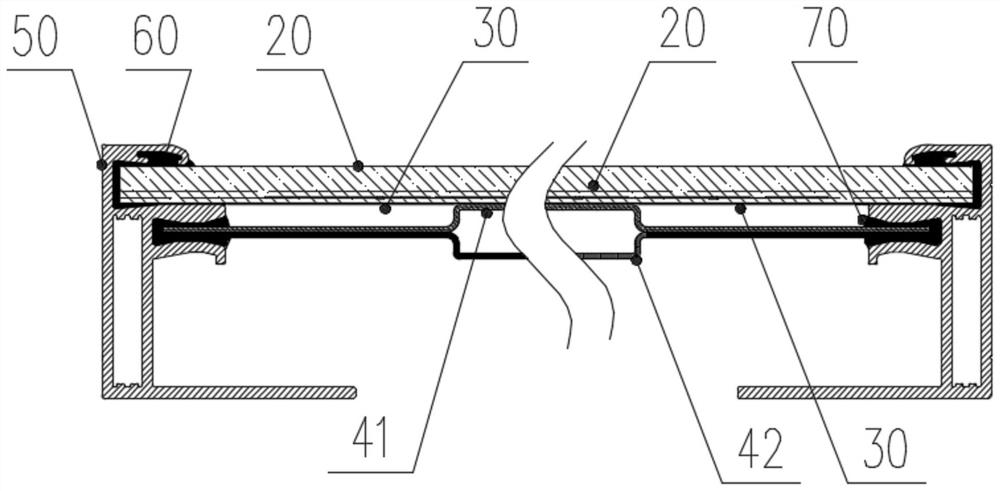

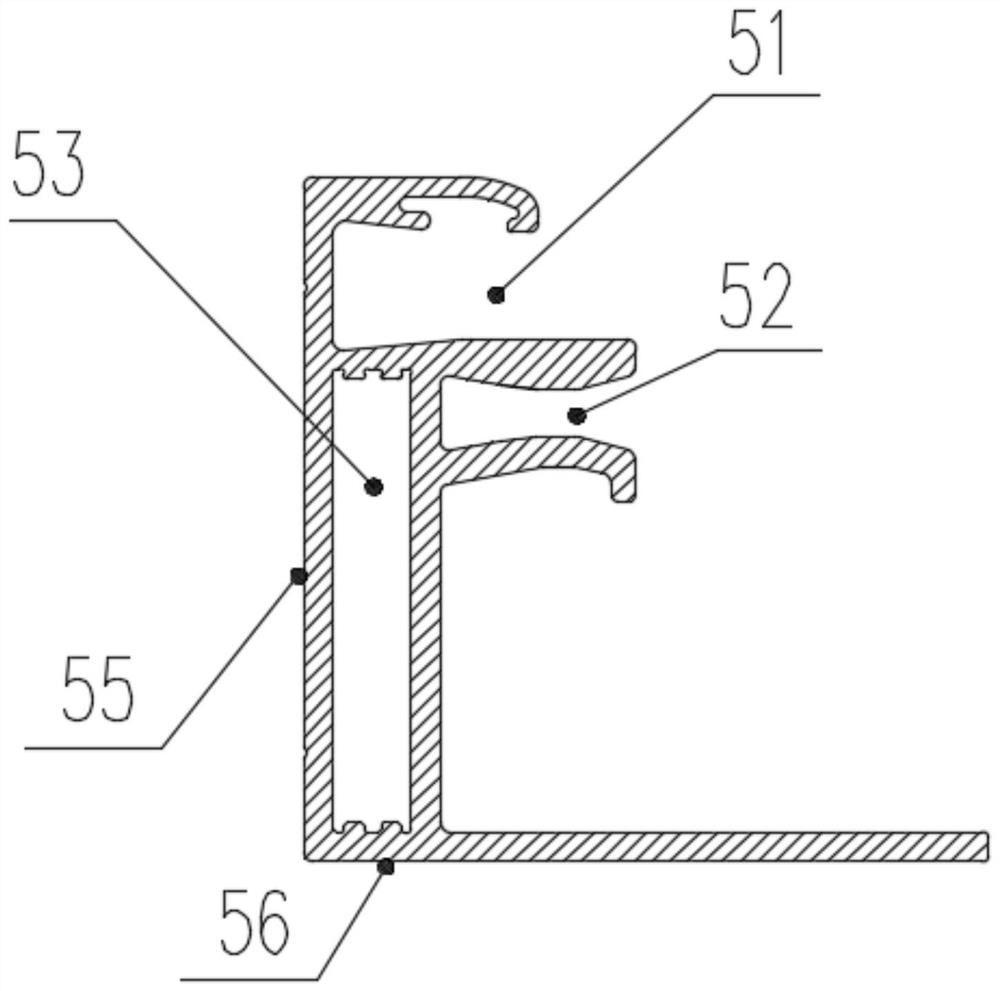

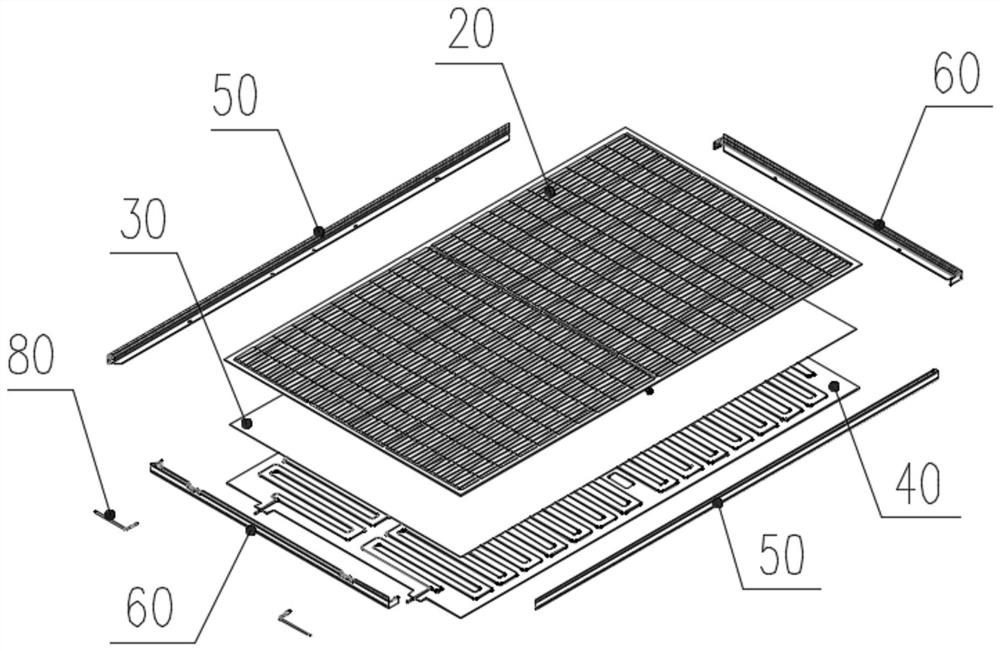

[0046] Please refer to Figure 1-11 , this embodiment mainly introduces a double-slot framed photovoltaic photothermal integrated assembly. The hot plate 40 is detachably installed in the assembly frame;

[0047] The middle part of the photovoltaic panel 20 is provided with a junction box and a lead wire, and the middle part of the heat collecting plate 40 is provided with a through hole corresponding to the junction box. The photovoltaic panel 20 absorbs light energy for photovoltaic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com