Incineration waste gas treatment device for solid waste treatment

A waste gas treatment device and waste gas treatment technology, applied in combined devices, incinerators, combustion methods, etc., can solve the problems of non-harmful treatment of fly ash, formation of acid rain, harm to the safety of the atmosphere, soil and water sources, and increase efficiency , increase agitation efficiency, increase the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

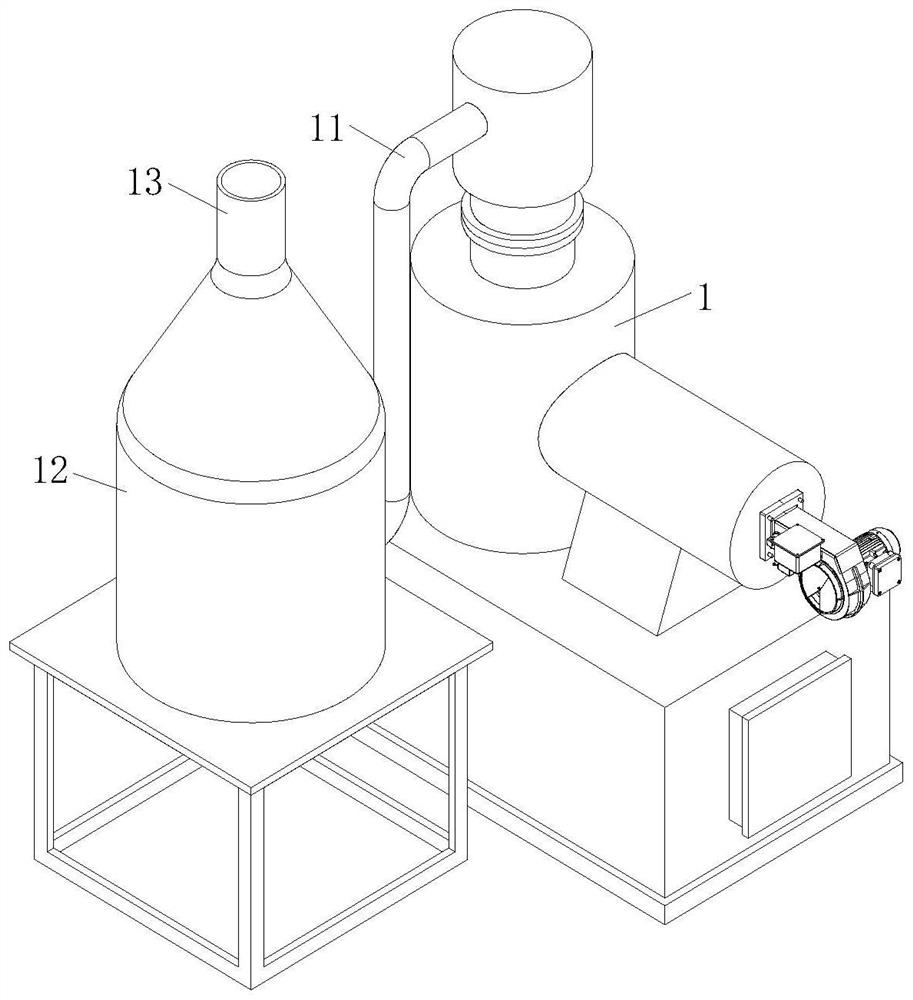

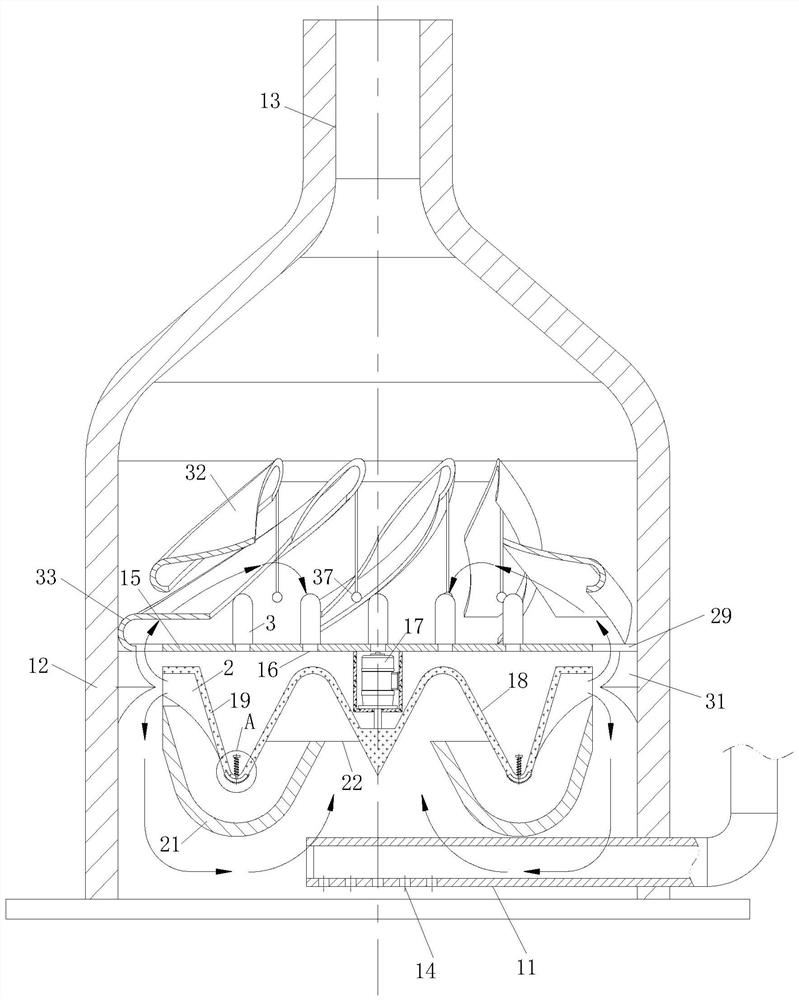

[0032] Such as Figure 1 to Figure 4 As shown, a kind of incineration waste gas treatment device for solid waste treatment according to the present invention includes an incinerator 1 and an exhaust pipe 11, the end of the exhaust pipe 11 is connected with a waste gas treatment cylinder 12, and the top of the waste gas treatment cylinder 12 is provided with a tail Trachea 13; calcium hydroxide solution is housed in the exhaust gas treatment cylinder 12, and the exhaust pipe 11 runs through the exhaust gas treatment cylinder 12 and extends to the middle of the exhaust gas treatment cylinder 12; the exhaust pipe 11 is closed at one end of the exhaust gas treatment cylinder 12, And the exhaust pipe 11 is located in the middle of the exhaust gas treatment cylinder 12, and a group of downward air injection ports 14 are evenly distributed; when working, the volume of solid waste in the prior art can be greatly reduced through combustion treatment, reducing the waste during solid wast...

Embodiment 2

[0041] Such as Figure 5 to Figure 7 Shown, comparative example one, wherein another kind of implementation mode of the present invention is:

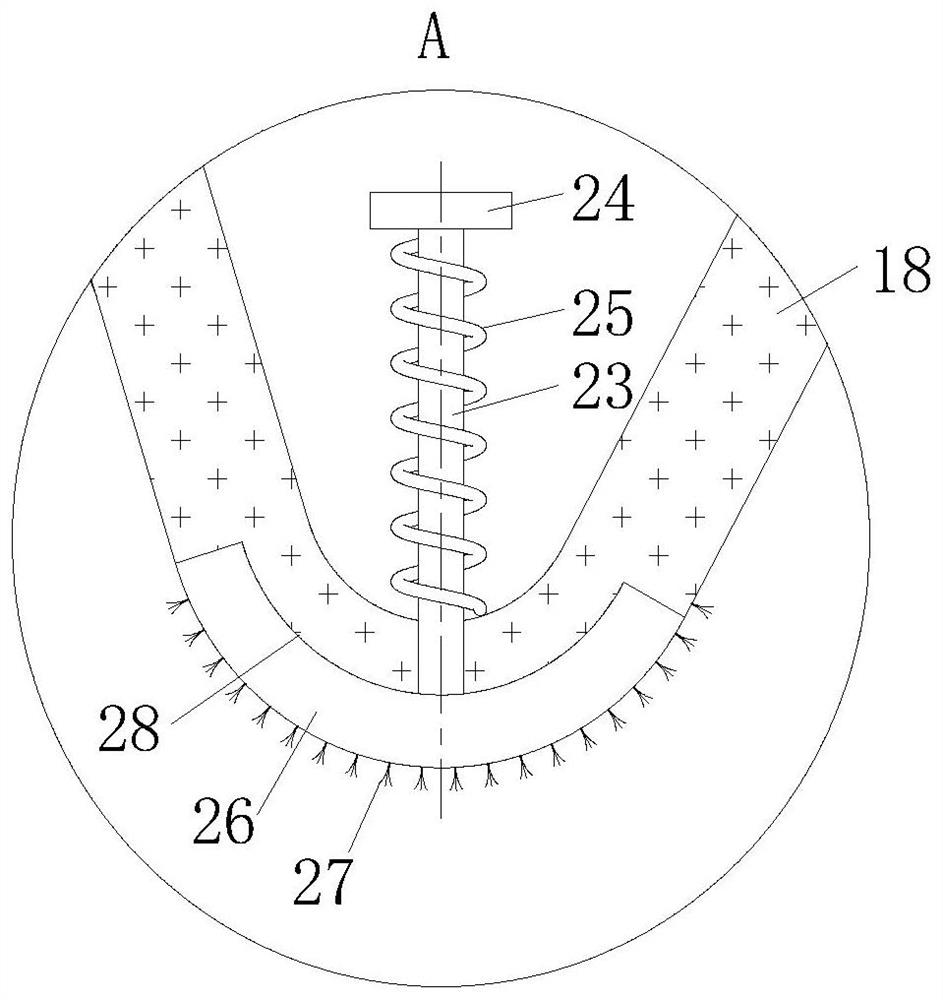

[0042] The top of the cloth bag 3 is provided with a No. 2 spring 38, and the inner diameter of the No. 2 spring 38 is greater than the outer diameter of the cloth bag 3; the top of the No. 2 spring 38 is fixedly connected with the No. 4 spring 4 and the No. 4. The top is fixedly connected with the deflector 32; after the cloth bag 3 is cyclically inflated, it continuously expands and blows upward, so that the top of the expanded cloth bag 3 touches the second spring 38 and inserts it into the second spring 38, and then relies on the magnet 36 to attract the second spring At 38 o'clock, the No. 2 spring 38 extrudes and rubs the outer periphery of the cloth bag 3 to further increase the crushing efficiency of the adhering impurities in the cloth bag 3. At the same time, when the top of the cloth bag 3 enters the conical No. 3 spring 39,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap