Positioning device for hydraulic piston cylinder body punching

A technology of hydraulic piston and positioning device, which is applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of increasing the labor burden of staff and difficult to clean debris, and achieves the effect of reducing burns and improving the collection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

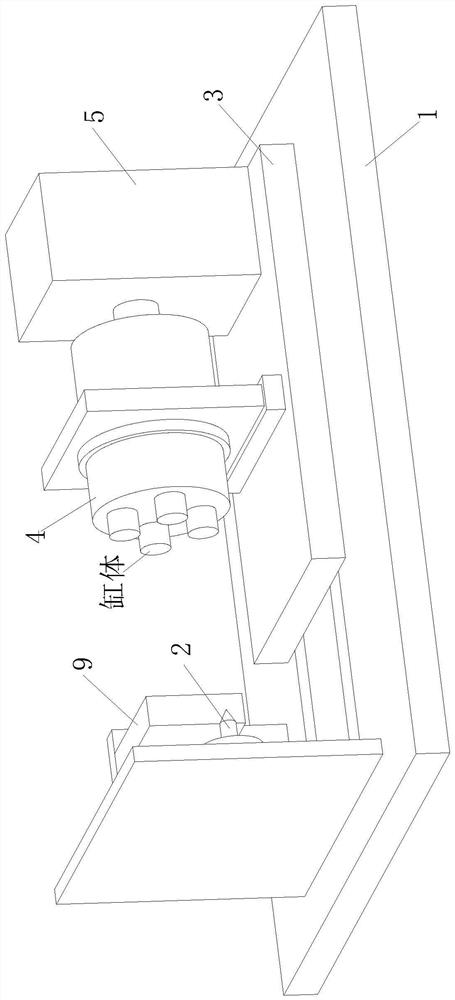

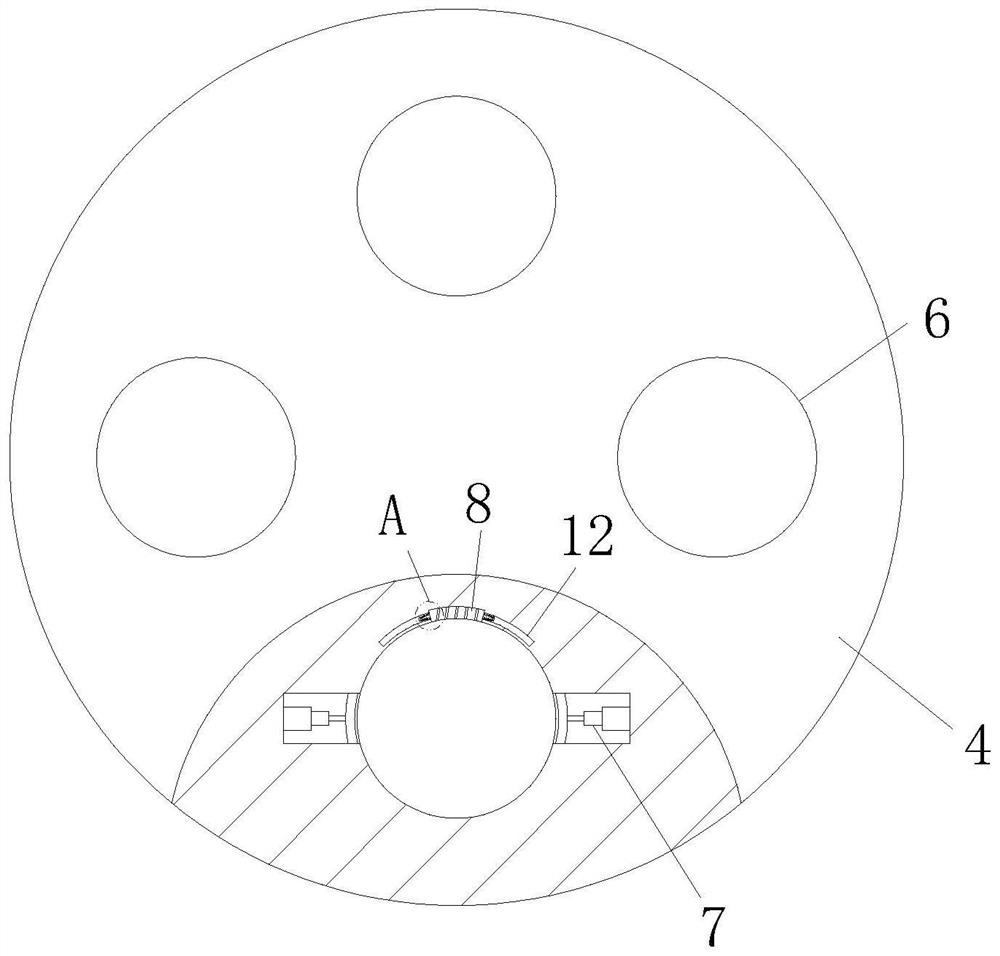

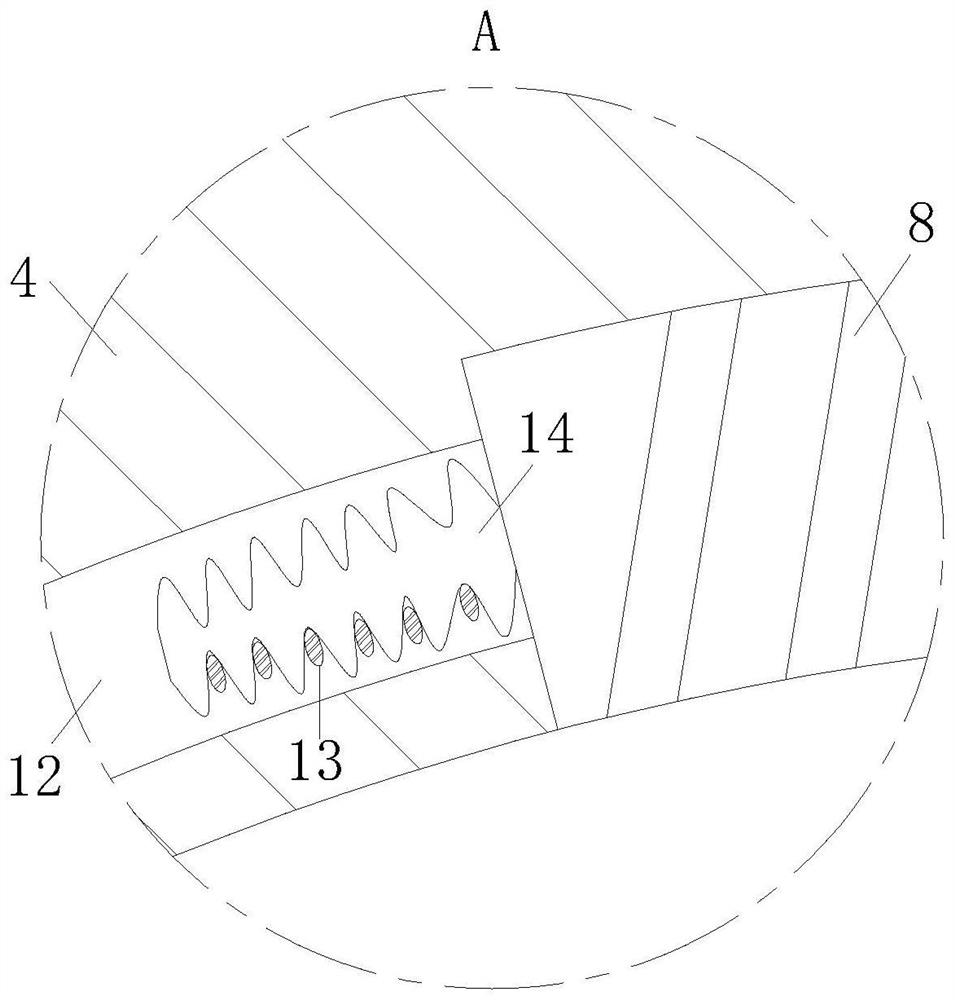

[0032] see Figure 1-Figure 5 As shown, a positioning device for punching a hydraulic piston cylinder according to an embodiment of the present invention includes a support base 1; a drill press 2 is provided on one side of the top surface of the support base 1; The slide table 3 is slidably connected with the drive assembly, and the top of the slide table 3 is connected with the positioning column 4 in rotation, and the side of the slide table 3 away from the drilling machine 2 is provided with a power assembly 5 that drives the positioning column 4 to rotate, and the positioning A group of positioning cavities 6 are provided on the end surface of the column 4 close to the drilling machine 2, and a clamping assembly 7 is arranged inside the positioning cavity 6, and a No. One end of 2 is connected with a blocking plate 9, and the side of the blocking plate 9 close to the positioning column 4 is provided with a negative pressure chamber 10 matched with the cylinder body, and t...

Embodiment 2

[0041] Such as Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is as follows: a set of chute is provided on the side wall where the scraper 20 and the filter screen 15 are attached, and the inside of the chute is slidably connected with a magnetic The sliding block 29 made of material, the elastic member 30 is connected between the sliding block 29 and the inner end of the chute, and the positions corresponding to the filter screen 15 and the chute are inlaid with several groups of ring-shaped and evenly distributed magnetic blocks 31 , the slider 29 can repel it when it moves to the magnetic block 31; when the scraper 20 rotates slowly on the filter screen 15, the slider 29 can slide back and forth in the chute under the action of the magnetic block 31, and The impact on the filter screen 15 promotes the falling of the iron filings adhered to the surface of the filter screen 15, further improving the cleaning effect of the iron filings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com