Core-shell structure carbon-based copper azide composite energetic material and preparation method thereof

A core-shell structure, copper nitride technology, applied in metal azide composition, carbon preparation/purification, azide acid/azide/halide azide, etc., can solve the problem of low content, composite energy The problem of low energy density of materials, etc., achieves the effect of reducing sensitivity, high energy insensitivity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

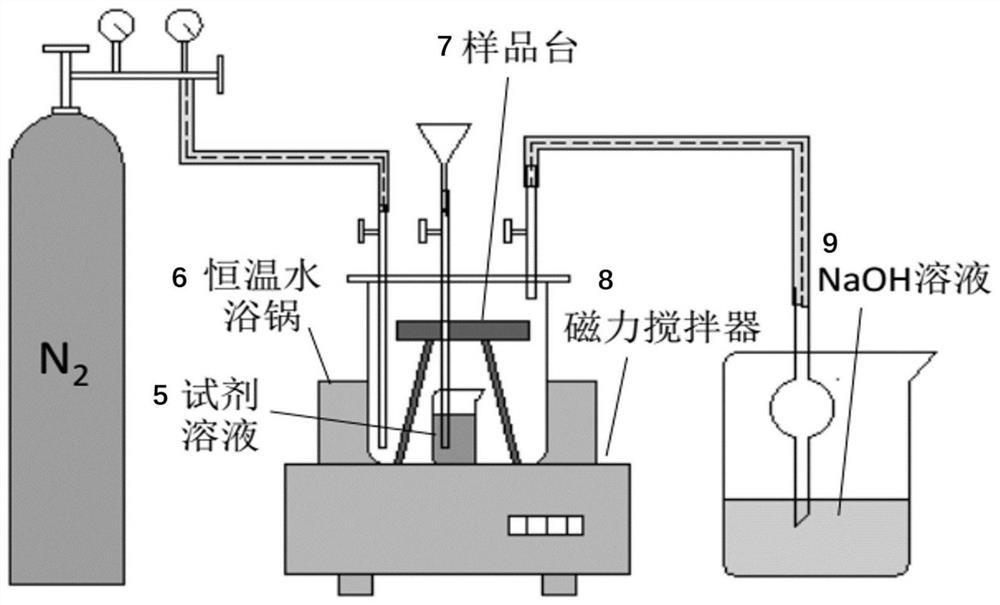

[0029] Preparation of core-shell carbon-based copper azide composite energetic materials:

[0030] In step 1, copper acetate (15 mmol), glucose (100 mmol) and polyvinylpyrrolidone (22.5 mmol) were respectively dissolved in 50 mL of diethylene glycol. After mixing the three solutions, the oil bath was heated to 100° C., magnetically stirred for 2 h, and the obtained product was washed and centrifuged to obtain cuprous oxide nanoparticles. Dissolve cuprous oxide nanoparticles (2.5 mmol) in 200 mL of benzyl alcohol to obtain a benzyl alcohol solution of cuprous oxide nanoparticles; 3 BTC (3.35 mmol) was dissolved in ethanol to give H 3 Ethanol solution of BTC. The benzyl alcohol solution of cuprous oxide nanoparticles was heated to 80 °C in a water bath, and the H 3 The ethanol solution of BTC was poured into the benzyl alcohol solution of cuprous oxide nanoparticles, and the solution was magnetically stirred for 2.5 h. The resulting Cu 2 The O@MOF hybrids were centrifuged a...

Embodiment 2

[0040] Preparation of core-shell carbon-based copper azide composite energetic materials:

[0041] In step 1, copper acetate (15 mmol), glucose (100 mmol) and polyvinylpyrrolidone (22.5 mmol) were respectively dissolved in 50 mL of diethylene glycol. The three solutions were mixed in an oil bath and heated to 100 °C, and magnetically stirred for 2 h. The resulting product was washed and centrifuged. The cuprous oxide nanoparticles were obtained; cuprous oxide (3 mmol) was dissolved in 200 mL of benzyl alcohol; the H 3 BTC (4 mmol) was dissolved in ethanol. The benzyl alcohol solution of cuprous oxide was heated to 80°C in a water bath, and the H 3 The ethanol solution of BTC was poured into the benzyl alcohol solution of cuprous oxide, and the solution was magnetically stirred for 2.5 h. The product is centrifuged and dried;

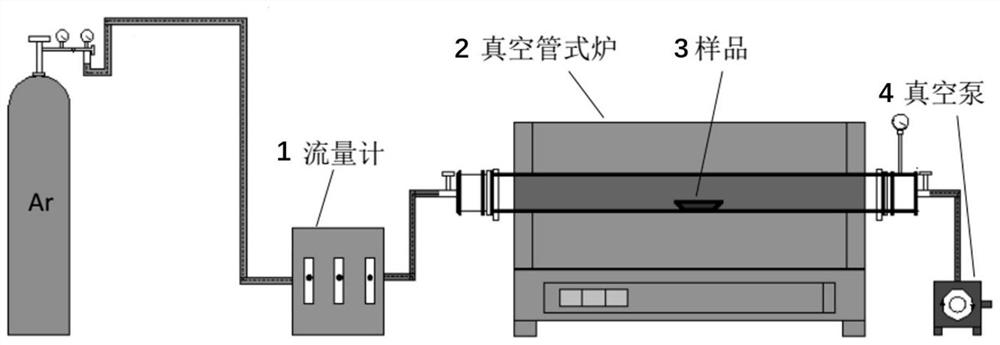

[0042] Step 2, put the sample into the middle of the corundum tube of the vacuum tube furnace, while heating, pass argon gas and turn on the vacuum...

Embodiment 3

[0045] Preparation of core-shell carbon-based copper azide composite energetic materials:

[0046] In step 1, copper acetate (15 mmol), glucose (100 mmol) and polyvinylpyrrolidone (22.5 mmol) were respectively dissolved in 50 mL of diethylene glycol. The three solutions were mixed in an oil bath and heated to 100 °C, and magnetically stirred for 2 h. The resulting product was washed and centrifuged. Cuprous oxide nanoparticles were obtained; cuprous oxide (2.8 mmol) was dissolved in 200 mL of benzyl alcohol; H 3 BTC (3.75 mmol) was dissolved in ethanol. The benzyl alcohol solution of cuprous oxide was heated to 80°C in a water bath, and the H 3 The ethanol solution of BTC was poured into the benzyl alcohol solution of cuprous oxide, and the solution was magnetically stirred for 2.5 h. The product is centrifuged and dried;

[0047] Step 2, put the sample into the middle of the corundum tube of the vacuum tube furnace, while heating, pass argon gas and turn on the vacuum pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com