Biodegradable sheet and preparation method thereof

A biodegradable and sheet technology, applied in the field of biodegradable sheet and its preparation, can solve the problems of reduced environmental protection strength, long degradation period, cumbersome preparation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

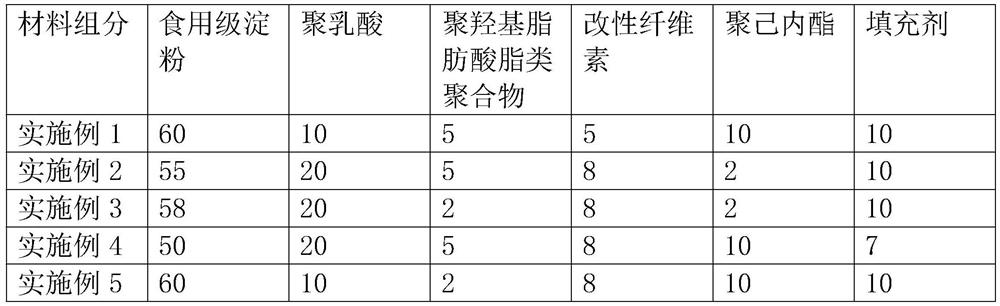

Embodiment 1

[0060] Embodiment 1: On the basis of the percentage content of 100%, the food grade starch content is 60%, polylactic acid 10%, polyhydroxy fatty acid lipid polymer 5%, modified fiber 5%, polycaprolactone 10%, Filling agent 10%, make the chemical reaction between food-grade starch and each raw material more fully, increase its own degradable strength;

Embodiment 2

[0061] Embodiment 2: On the basis of percentage content 100%, edible grade starch content is 55%, polylactic acid 20%, polyhydroxy fatty acid lipid polymer 5%, modified fiber 8%, polycaprolactone 2%, Filling agent 10%, on the basis of Example 1, reduce the proportion of food-grade starch and polycaprolactone content, increase the proportion of polylactic acid and modified cellulose content, further improve the reaction rate of food-grade starch, and its formed sheet The degradable strength of the material;

Embodiment 3

[0062] Embodiment 3: On the basis of percentage content 100%, edible grade starch content is 58%, polylactic acid 20%, polyhydroxy fatty acid lipid polymer 2%, modified fiber 8%, polycaprolactone 2%, The filling agent is 10%, and on the basis of Example 1, the proportion of food-grade starch, polyhydroxy fatty acid lipid polymer and polycaprolactone is reduced, so as to reduce the amount of single preparation and ensure the overall degradable strength of the sheet .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com