Engine suspension packing cup rubber material, preparation method thereof and engine suspension

A technology for engine mounts and leather cups, which is applied to engine mount rubber materials, the preparation of the above-mentioned engine mount rubber materials, and the field of engine mounts, which can solve the problems that are difficult to meet the requirements of automobile life, air tightness and long-term Liquid resistance, high temperature resistance, poor weather resistance, fatigue strength, poor bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

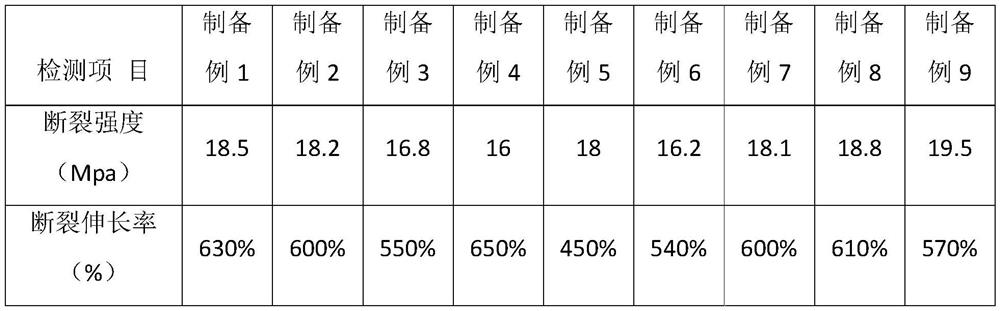

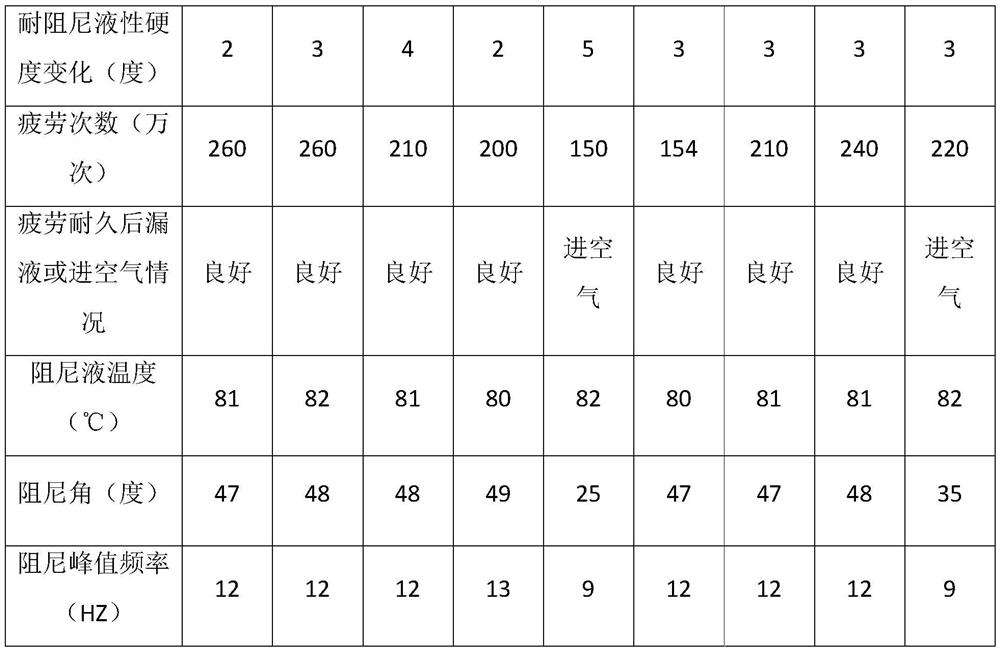

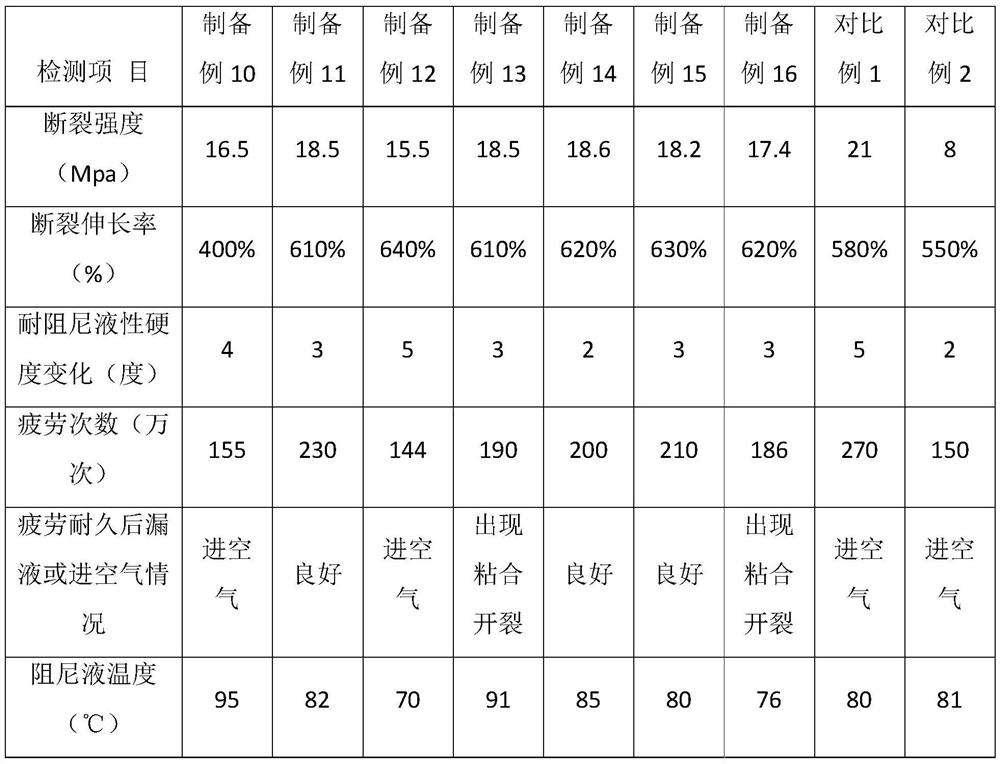

Examples

Embodiment 1

[0028] This embodiment relates to an engine suspension rubber material, which is made of the following components in parts by weight in terms of overall design: polyisoprene rubber: 65-75 parts, isobutylene and p-methylstyrene copolymerized Compound: 35-25 parts, rubber leveling agent 40msf: 4.5-5.5 parts, hydrated aluminum silicate: 15-20 parts, aminosilane coupling agent: 1.5-2.5 parts, iron oxide: 4.5-5.5 parts, zinc oxide: 3.0 -5.0 parts, stearic acid: 1.0-2.0 parts, carbon black: 20-30 parts, naphthenic oil: 5-15 parts, antioxidant: 3.8-8 parts, sulfur: 0.75-0.85 parts, accelerator: 3.70- 4.35 parts, anti-scorch agent: 0.2-0.3 parts.

[0029] Among them, polyisoprene rubber is an organic substance composed of cis-1,4-polyisoprene, and is generally mainly used for manufacturing tires, molded products, and the like. Isobutylene and p-methylstyrene copolymer is a rubber product with excellent properties. It not only has the good air tightness and high damping properties of ...

preparation example 1

[0044] In this preparation example 1, the engine mount rubber material is made of the following components in parts by weight: polyisoprene rubber: 70 parts, isobutylene and p-methylstyrene copolymer: 30 parts, and the rubber is uniform Agent 40msf: 5 parts, hydrated aluminum silicate: 20 parts, γ-aminopropylmethyldiethoxysilane: 2 parts, iron oxide: 5 parts, zinc oxide: 5 parts, stearic acid: 1 part, charcoal Black N550: 20 parts, naphthenic oil: 5 parts, antioxidant TMQ: 1.5 parts, antioxidant 4010NA: 1.5 parts, antioxidant 4020: 1.5 parts, antioxidant MB: 1.5 parts, sulfur: 0.8 parts, dimethyl disulfide Diphenylthiuram: 1.5 parts, N-oxydiethylenethiocarbamoyl-N'-oxydiethylenesulfenamide: 1.65 parts, 2-mercaptobenzothiazole zinc Salt: 1.0 parts, anti-scorch agent: 0.2 parts.

[0045] For the preparation method of the rubber material for the engine mount cup in Preparation Example 1, refer to the preparation method described above.

preparation example 2

[0047] In this preparation example 2, the engine mount rubber material is made of the following components in parts by weight: polyisoprene rubber: 70 parts, isobutylene and p-methylstyrene copolymer: 30 parts, and the rubber is uniform Agent 40msf: 5.5 parts, hydrated aluminum silicate: 20 parts, γ-aminopropylmethyldiethoxysilane: 2 parts, iron oxide: 5 parts, zinc oxide: 5 parts, stearic acid: 1 part, charcoal Black N550: 20 parts, naphthenic oil: 5 parts, antioxidant TMQ: 1.5 parts, antioxidant 4010NA: 1.5 parts, antioxidant 4020: 1.5 parts, antioxidant MB: 1.5 parts, sulfur: 0.8 parts, dimethyl disulfide Diphenylthiuram: 1.5 parts, N-oxydiethylenethiocarbamoyl-N'-oxydiethylenesulfenamide: 1.65 parts, 2-mercaptobenzothiazole zinc Salt: 1.0 parts, anti-scorch agent: 0.2 parts.

[0048] For the preparation method of the rubber material for the engine mount cup in Preparation Example 2, refer to the preparation method described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com