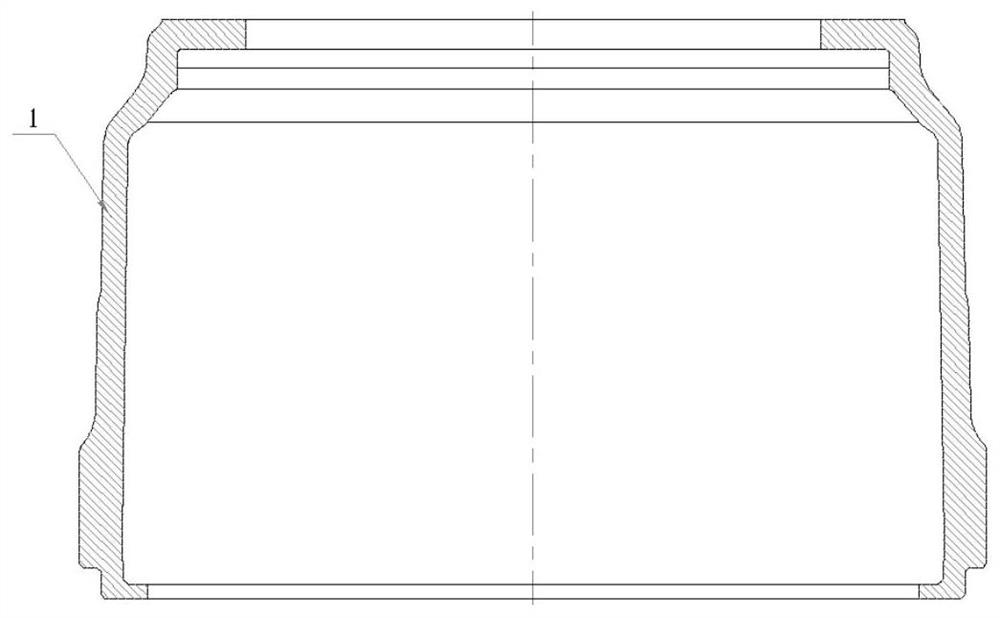

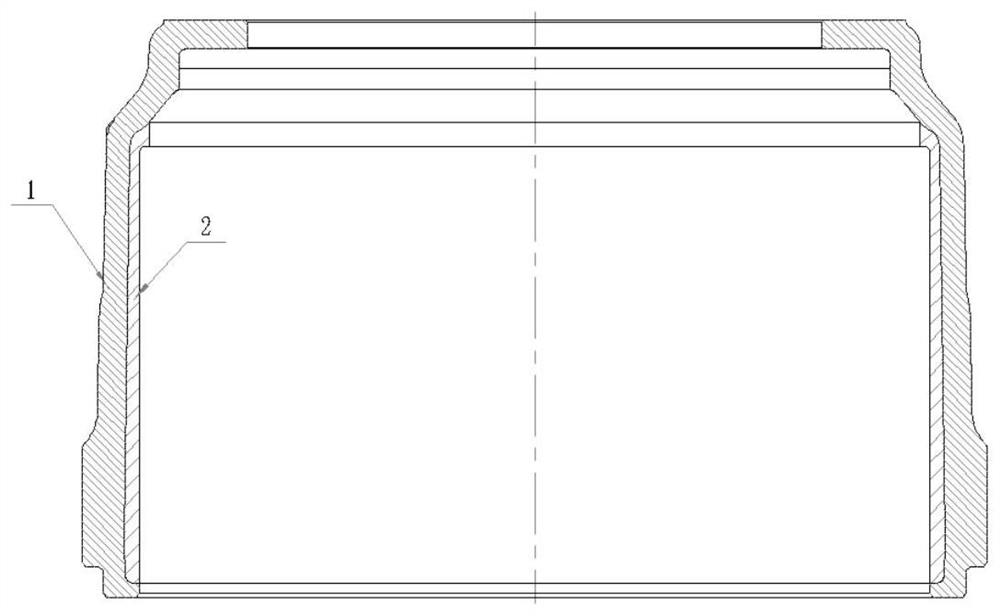

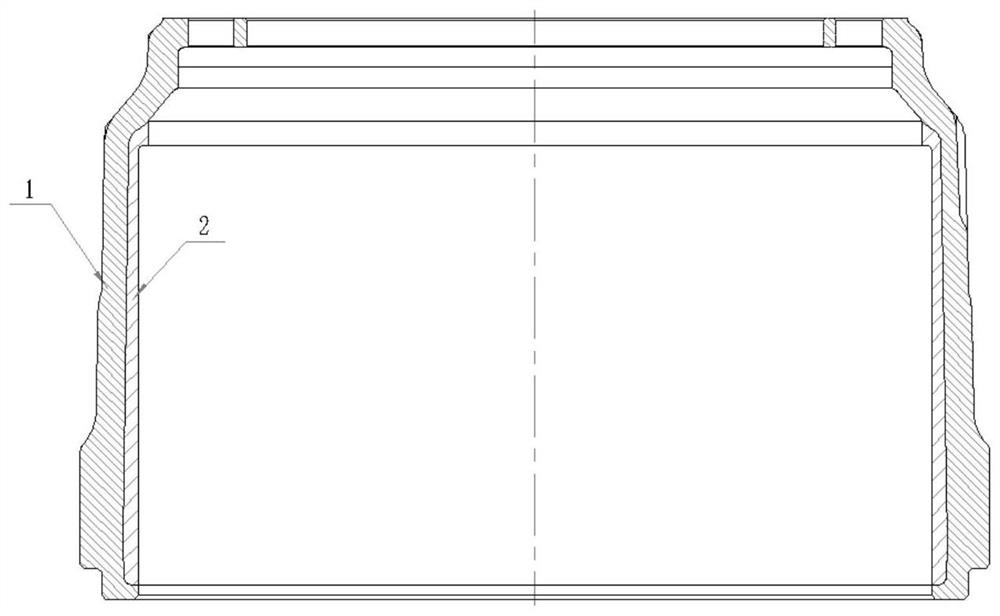

Bimetal centrifugal composite brake drum and preparation method thereof

A centrifugal composite and brake drum technology, applied in the field of automobile manufacturing, can solve the problems of inability to use high-strength medium-carbon low-alloy steel, complex composite brake drum technology, increased brake drum weight, etc., and achieves high production efficiency and weight. Lightening, high material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A bimetallic centrifugal composite brake drum and a preparation method thereof, and the outer layer is made of high-strength carbon low alloy steel, first use centrifugal casting methods to produce medium carbon low alloy steel steel cylinders, and use die forging into composite brakes The tumpet steel shell 1 is then poured on the centrifuge, and the bimetallic centrifugation is obtained, and the specific preparation process step is as follows:

[0028] 1 First in the medium-frequency induction electric furnace, the carbon low alloy steel is melted, and the chemical composition and mass fraction of the medium carbon low alloy steel are controlled at: 0.31% C, 0.37% Si, 0.55% Mn, 0.51% Cr, 0.08% Ti, 0.02% N, 0.003% B, 0.095% Al, 0.0022% Mg, 0.051% Ca, 0.027% CE, 0.023% S, 0.031% p, margin Fe; steel water added 0.08% waste aluminum wire deoxidation, temperature When the 1612 ° C is released; the steel water is allowed to stand, after the slag, the temperature is 1503 ° C, th...

Embodiment 2

[0033] A bimetallic centrifugal composite brake drum and a preparation method thereof, and the outer layer is made of high-strength carbon low alloy steel, first use centrifugal casting methods to produce medium carbon low alloy steel steel cylinders, and use die forging into composite brakes The tumpet steel shell 1 is then poured on the centrifuge, and the bimetallic centrifugation is obtained, and the specific preparation process step is as follows:

[0034] 1 First in the molten induction electric furnace, the carbon low alloy steel is melted, and the chemical composition and mass fraction of the medium carbon low alloy steel are controlled at: 0.43% C, 0.19% Si, 0.77% Mn, 0.36% Cr, 0.15% Ti, 0.06% N, 0.006% B, 0.068% Al, 0.0035% mg, 0.035% Ca, 0.048% CE, 0.021% S, 0.029% P, margin Fe; steel water added 0.12% waste aluminum wire deoxidation, temperature When the 1627 ° C is released; the steel water is allowed to stand, after the slag, the temperature is 1520 ° C, the casting ...

Embodiment 3

[0039] A bimetallic centrifugal composite brake drum and a preparation method thereof, and the outer layer is made of high-strength carbon low alloy steel, first use centrifugal casting methods to produce medium carbon low alloy steel steel cylinders, and use die forging into composite brakes The tumpet steel shell 1 is then poured on the centrifuge, and the bimetallic centrifugation is obtained, and the specific preparation process step is as follows:

[0040] 1 First in the molten induction electric furnace, the carbon low alloy steel is melted, and the chemical composition and mass fraction of the medium carbon low alloy steel are controlled at: 0.38% C, 0.26% Si, 0.59% Mn, 0.47% Cr, 0.12% Ti, 0.05% N, 0.005% B, 0.085% Al, 0.0027% mg, 0.041% Ca, 0.036% CE, 0.028% S, 0.030% p, margin Fe; steel water added 0.10% waste aluminum wire deoxidation, temperature When the 1623 ° C is released; the steel water is allowed to stand, after the slag, the temperature is 1514 ° C, the casting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com