Material thermal conductivity testing method and device convenient to operate

A test method and a technology that is easy to operate. It is applied in the direction of material thermal development and material thermal conductivity. It can solve the problems of inability to calibrate the heat flow meter, long measurement time, and complicated devices. It achieves a simple and clear test process, meets economic requirements, and avoids The effect of heavy investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

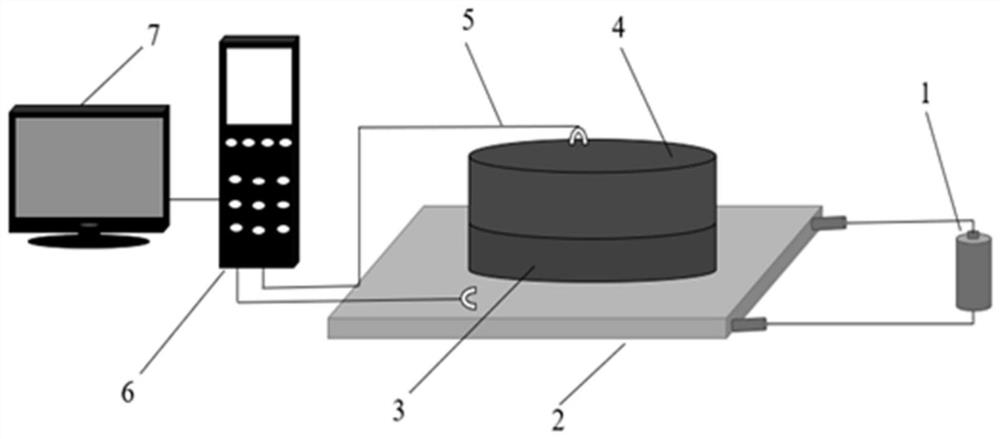

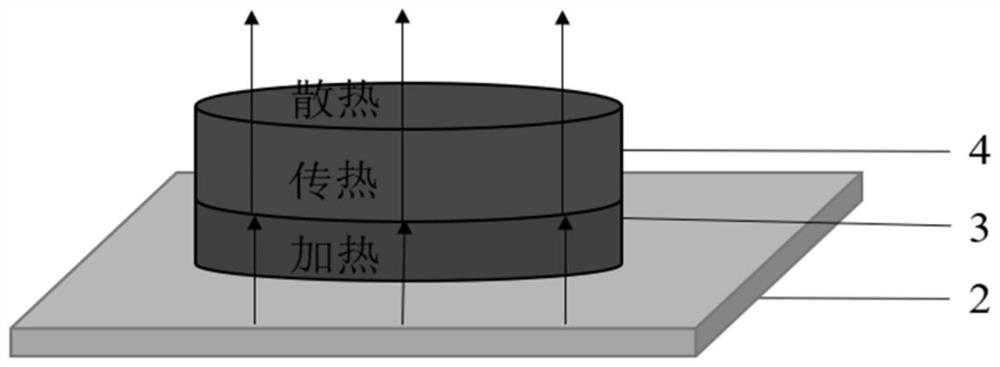

Method used

Image

Examples

Embodiment 1

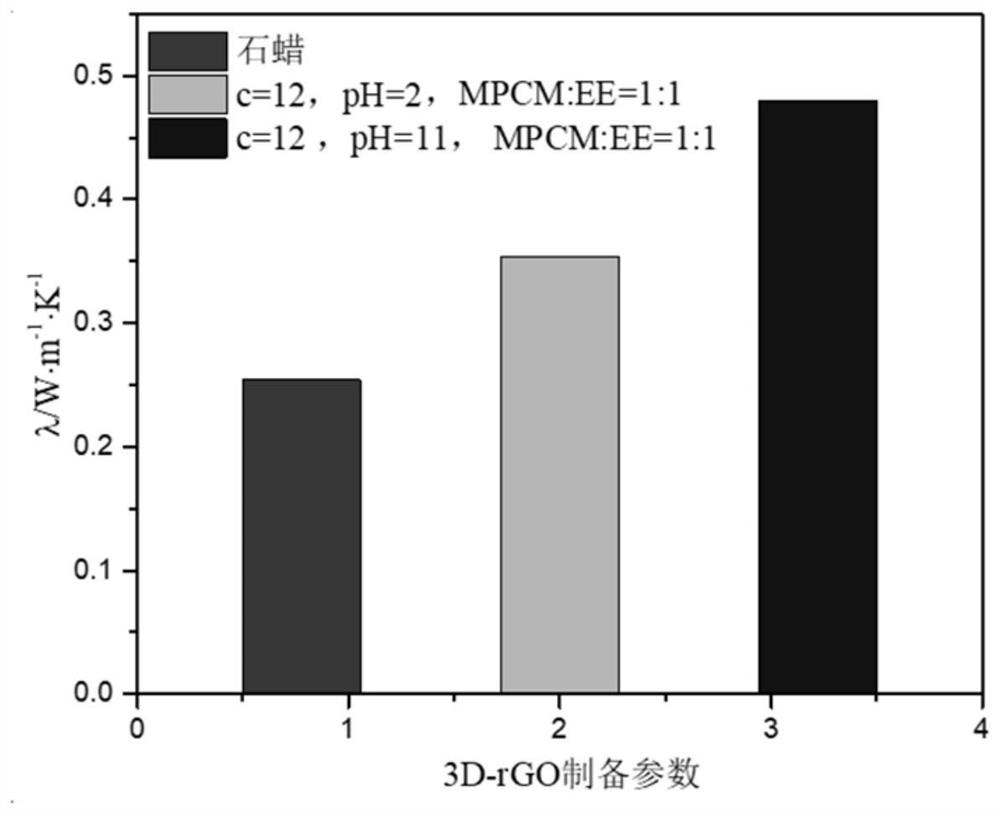

[0072] Adopt the present invention to carry out thermal conductivity test to the pure paraffin that Sinopharm Chemical Reagent Co., Ltd. provides, test result is as follows image 3 Shown in column 1, the thermal conductivity of the paraffin wax tested by the inventive method is 0.254W m -1 ·K -1 ; Simultaneously adopt MDSC thermal conductivity test method to test the thermal conductivity of paraffin wax, test result is as follows Figure 4 As shown in curve c, the thermal conductivity of paraffin wax tested by MDSC method is 0.224W·m -1 ·K -1 . Under the two different test methods, the test results of thermal conductivity are in good agreement.

Embodiment 2

[0074] Adopt the method of the present invention to test the thermal conductivity of the elastic phase-change composite material prepared by vacuum impregnation method, the composite material comprises elastic emulsion (EE), phase-change material and heat-conducting filling material, wherein the phase-change material is paraffin, and the heat-conducting filling material three-dimensional graphene airgel. Among them, the paraffin wax is provided by Sinopharm Chemical Reagent Co., Ltd., the specification is chemically pure, the melting point is 48-52°C, and the density is 0.86g / cm 3 ; 200-mesh natural flake graphite was provided by Shanghai Yifan Graphite Products Co., Ltd. Test results such as image 3 As shown in column 2, the thermal conductivity of the elastic phase change composite material prepared under the conditions of graphene oxide pH of 2, concentration of 12mg / ml, and MPCM:EE of 1:1 is 0.354W m -1 ·K -1 , while using the MDSC thermal conductivity test method to t...

Embodiment 3

[0076]Adopt the method of the present invention to test the thermal conductivity of the elastic phase-change composite material prepared by vacuum impregnation method, the composite material comprises elastic emulsion (EE), phase-change material and heat-conducting filling material, wherein the phase-change material is paraffin, and the heat-conducting filling material three-dimensional graphene airgel. Among them, the paraffin wax is provided by Sinopharm Chemical Reagent Co., Ltd., the specification is chemically pure, the melting point is 48-52°C, and the density is 0.86g / cm 3 ; 200-mesh natural flake graphite was provided by Shanghai Yifan Graphite Products Co., Ltd. Test results such as image 3 As shown in column 3, the thermal conductivity of the elastic phase change composite material prepared under the conditions of graphene oxide pH 11, concentration 12mg / ml, MPCM:EE 1:1 is 0.480W m -1 ·K -1 , while using the MDSC thermal conductivity test method to test the therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific heat capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com