Error-proofing and traceability management method applied to commercial vehicle electronic control system

An electronic control system and management method technology, applied in the automotive field, can solve the problems of low efficiency, inconvenient management, and inability to check the software information of electronic control components, etc., to achieve the effect of improving operating efficiency, facilitating and rapid checking, and avoiding human interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

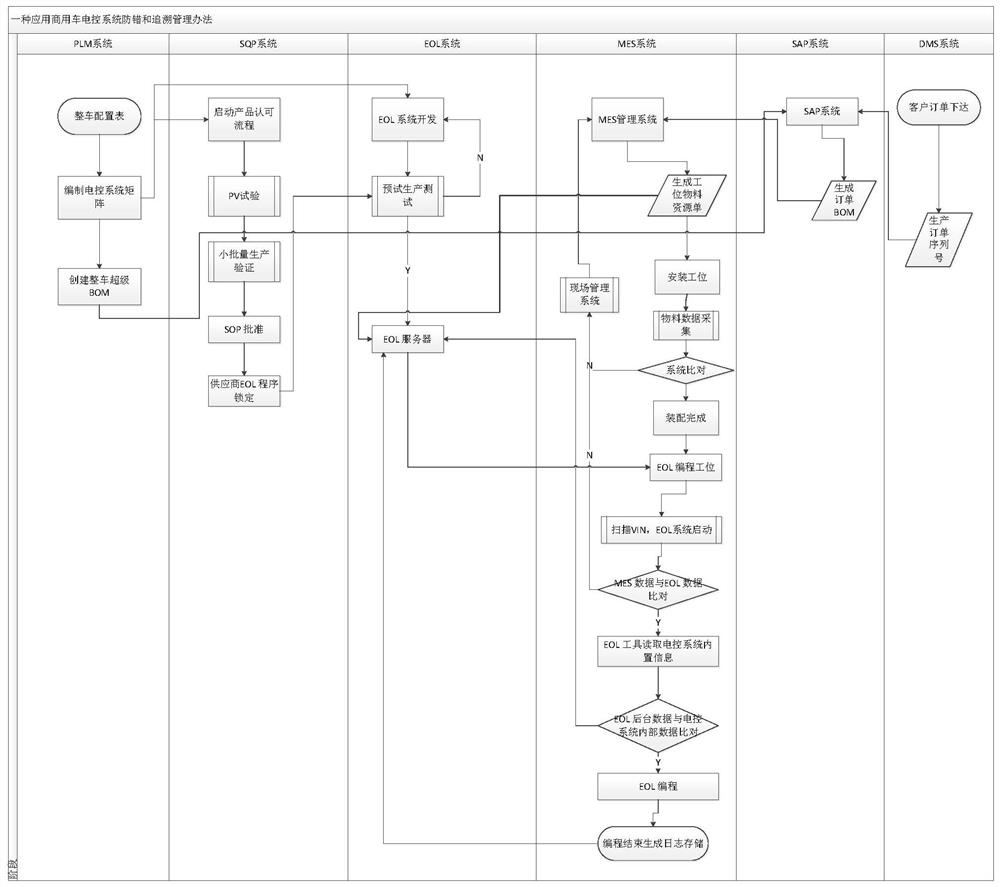

[0031] Example: such as figure 1 As shown, a method for error prevention and traceability management of an electronic control system for a commercial vehicle includes the following steps:

[0032] In the PLM (Product lifecycle management) product data management system, the product development engineer uses the information in the vehicle configuration table as a separate functional group to compile the electronic control component group matrix according to the vehicle BOM (Bill of Material) super bill of materials management method , and create a vehicle super bill of materials, enter the vehicle BOM super bill of materials management;

[0033] S2: The offline testing engineer develops software based on the data source of the electronic control component group matrix of the development engineer, and locks the information in the variable database;

[0034] S3: After the SQE (Supplier Quality Engineering) supplier quality management engineer receives the electronic control comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com