Electronic paste and application thereof in solar cell

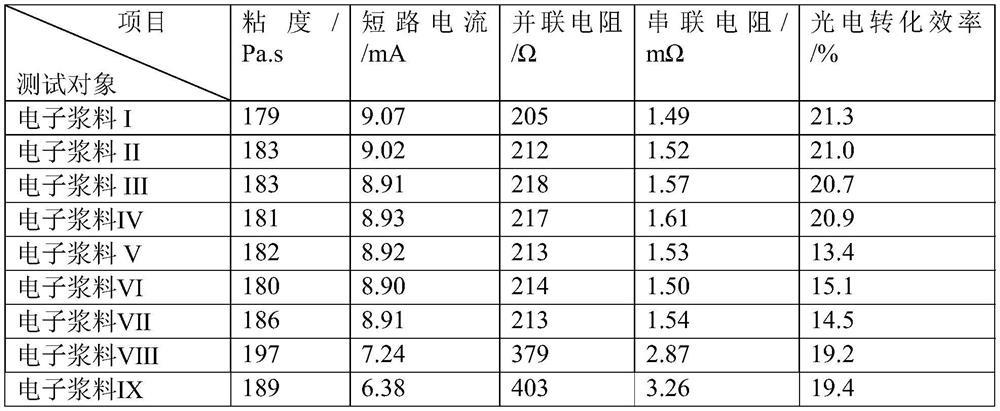

An electronic paste and glass powder technology, applied in the field of solar cell materials, can solve the problems of low conversion efficiency, poor reliability and low conductivity of solar cells, and achieve the effects of excellent ohmic contact, prevention of excessive sintering, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] According to the technical solution provided by the second aspect of the present invention, the preparation method of the electronic paste of the first aspect comprises the following steps:

[0065] P1: At room temperature, put silver-coated copper powder and glass powder into the container first, and mix well to obtain a premix;

[0066] P2: At room temperature, sequentially add an organic carrier and an inhibitor to the premix, and stir until uniform;

[0067] P3: Grinding to obtain a uniformly ground slurry crude product;

[0068] P4: Carrying out vacuum centrifugation and defoaming of the homogeneously ground slurry crude product to finally obtain the electronic slurry.

[0069] The technical solution provided according to the third aspect of the present invention is the application of the electronic paste described in the first aspect in solar cells. Specifically, the electrode containing the electronic paste described in the first aspect can be used in the solar...

Embodiment 1

[0072] Prepare glass powder α according to the following steps:

[0073] S1: Weigh 42wt% SiO according to mass percentage 2 , 25wt% Bi 2 o 3 , 13wt%TeO 2 , 9wt% BaCO 3 , 8.5wt% MgO, 1.4wt% TiO 2 and 1.1 wt% Al 2 o 3 , placed in a crucible, and mixed evenly;

[0074] S2: Heating in a muffle furnace to melt into molten glass; the heating temperature is 790°C, and the heating duration is 40 minutes;

[0075] S3: Pour the glass liquid into deionized water for quenching to make coarse glass powder;

[0076] S4: Pulverizing the prepared coarse glass powder by a ball mill to produce the glass powder α with an average particle size of 300-400 nm.

Embodiment 2

[0078] Prepare glass frit β according to the following steps:

[0079] S1: Weigh 45wt% SiO according to mass percentage 2 , 22wt% Bi 2 o 3 , 14wt%TeO 2 , 7wt% BaCO 3 , 6.8wt% MgO, 3wt% TiO2 and 2.2 wt% Al 2 o 3 , placed in a crucible, and mixed evenly;

[0080] S2: Heating in a muffle furnace to melt into molten glass; the heating temperature is 790°C, and the heating duration is 40 minutes;

[0081] S3: Pour the glass liquid into deionized water for quenching to make coarse glass powder;

[0082] S4: Pulverizing the prepared coarse glass powder by a ball mill to produce the glass powder β with an average particle size of 300-400 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com