Electrolyte for supercapacitor and supercapacitor

A supercapacitor and electrolyte technology, applied in the direction of hybrid capacitor electrolyte, etc., can solve the problems of supercapacitor difficulty and work, and achieve the effect of pressure resistance, high conductivity, inhibition of crystallization and even solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

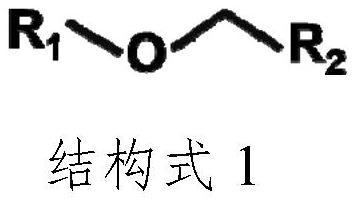

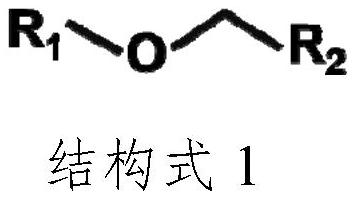

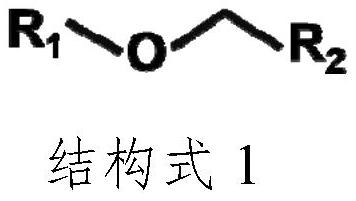

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is used to illustrate the capacitor electrolyte, supercapacitor and preparation method thereof disclosed in the present invention, including the following steps:

[0049] In the glove box, mix tetrafluoroethyl tetrafluoropropyl ether and acetonitrile, the mass ratio of the two is 1:1, mix well and then add N,N-dimethylpyrrolidine ammonium tetrafluoroborate to form electrolyte salt The concentration is 0.8mol / L electrolyte.

[0050] A supercapacitor model was assembled in a glove box: the cell consisted of two collector electrodes made of aluminum foil, two working electrodes made of activated carbon, and a fiber cloth diaphragm inserted between them. The cells were immersed in the electrolyte solutions in the following comparative examples and examples, and sealed with an aluminum case and colloidal particles to obtain a supercapacitor.

Embodiment 2~13

[0052] Embodiments 2 to 13 are used to illustrate the supercapacitor electrolyte, supercapacitor and preparation method thereof disclosed in the present invention, including most of the operating steps in Example 1, the difference being:

[0053] The main solvents, co-solvents, electrolyte salts and their addition amounts shown in Examples 2-13 in Table 1 were used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com