Rubber composition for torsional vibration damper

A technology of torsional vibration damper and rubber composition, applied in the direction of shock absorber, spring/shock absorber functional characteristics, shock absorber, etc. Good performance, prevention of discharge noise, high attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

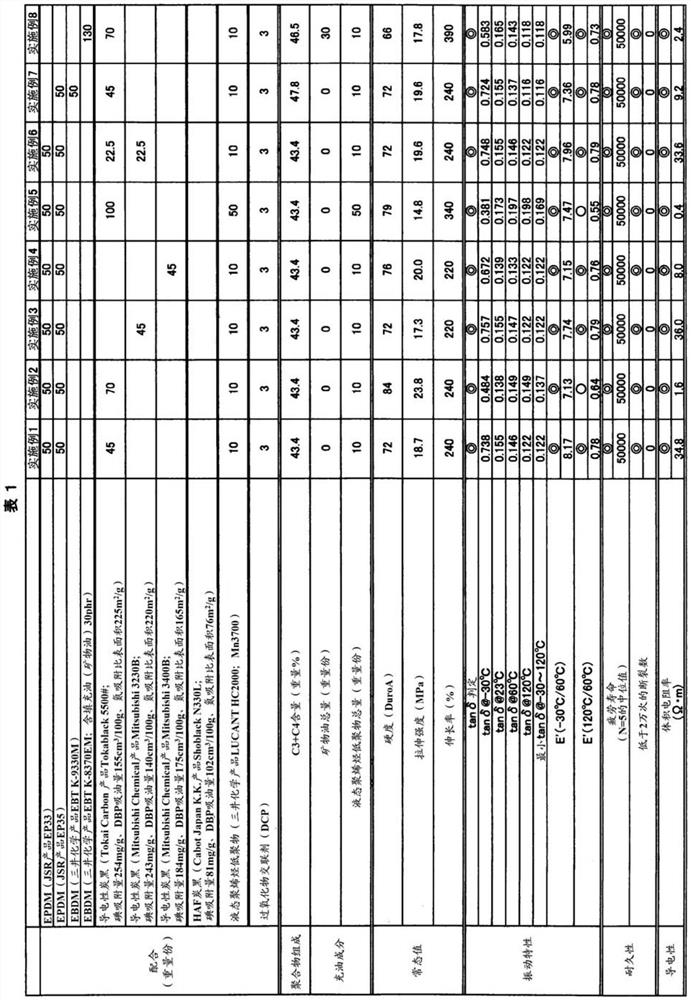

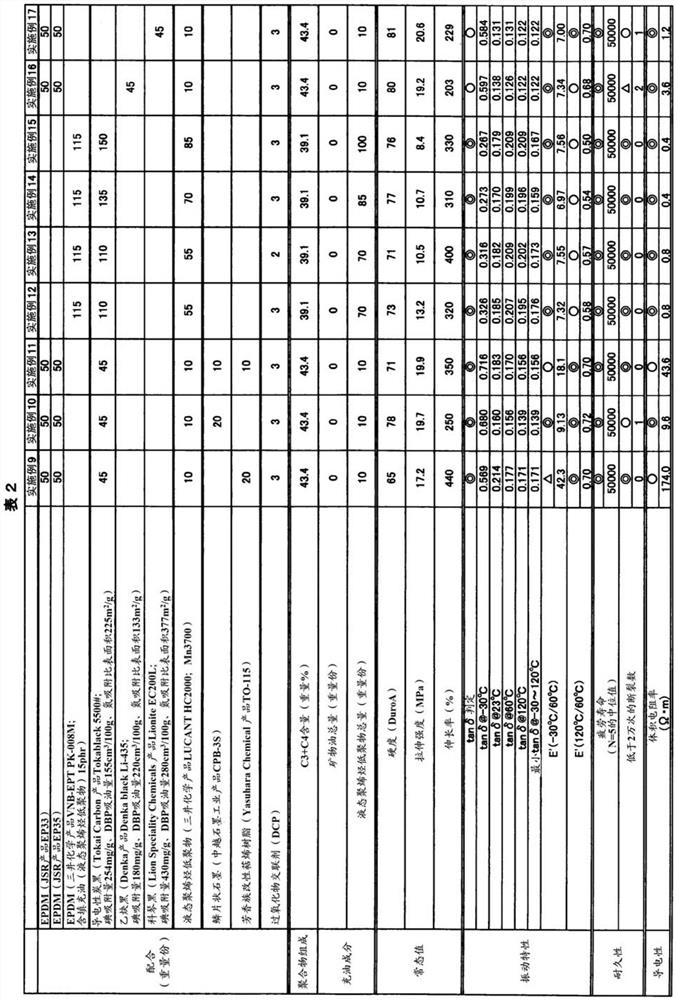

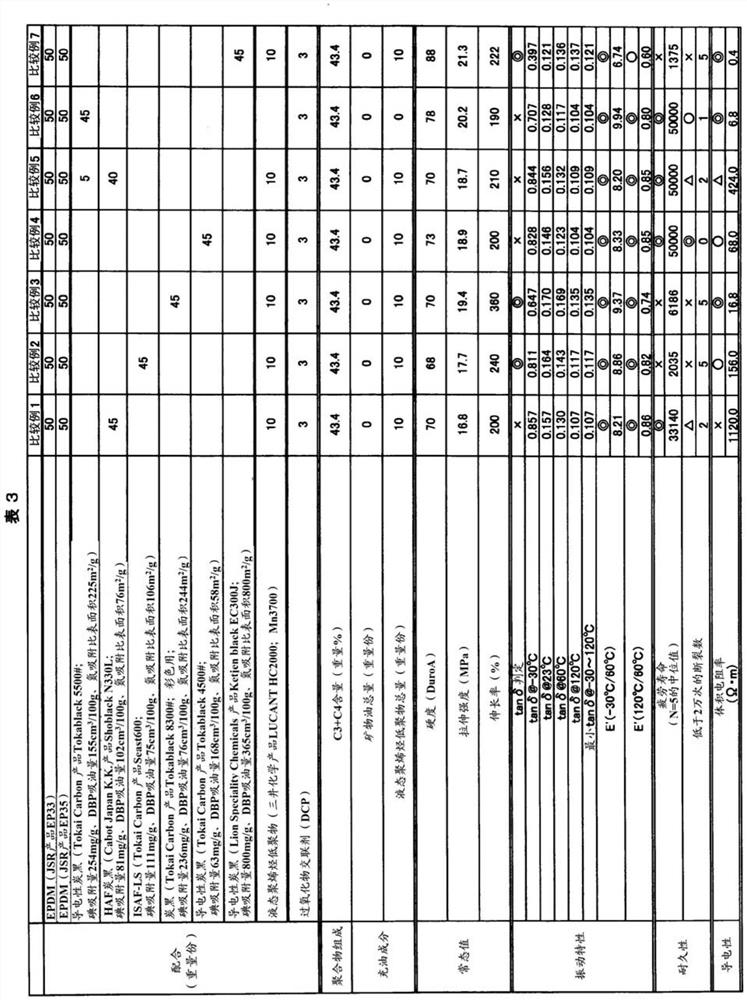

Embodiment 1~17、 comparative example 1~7

[0065] In addition to the compounding contents of the polymer, carbon black, liquid polyolefin oligomer, graphite, aromatic modified terpene resin, and organic peroxide crosslinking agent shown in Tables 1 to 3, the above descriptions are also appropriately added The matching reagents are used to prepare the composition.

[0066] In this embodiment, in order to manufacture the rubber composition for a torsional vibration damper, first, an unvulcanized rubber composition is prepared. The rubber composition is prepared by kneading prescribed raw materials using a mixer such as an internal mixer, a kneader, or a Banbury mixer, or an open roll. Then, using a press vulcanizer, compression molding machine, injection molding machine, etc., the blanks prepared above were subjected to primary vulcanization at 180° C. for 6 minutes and secondary vulcanization at 150° C. for 5 hours to produce test pieces with a thickness of 2 mm.

[0067] Kneading and roll workability were evaluated by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption | aaaaa | aaaaa |

| iodine adsorption | aaaaa | aaaaa |

| iodine adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com