Environment-friendly emulsion explosive

An emulsion explosive, environmentally friendly technology, applied in explosives, explosive composite components, explosive processing equipment and other directions, can solve problems such as reducing the use effect of explosives, and achieve the effects of improving water-hydrolysis capacity, water-blocking performance, and detonation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

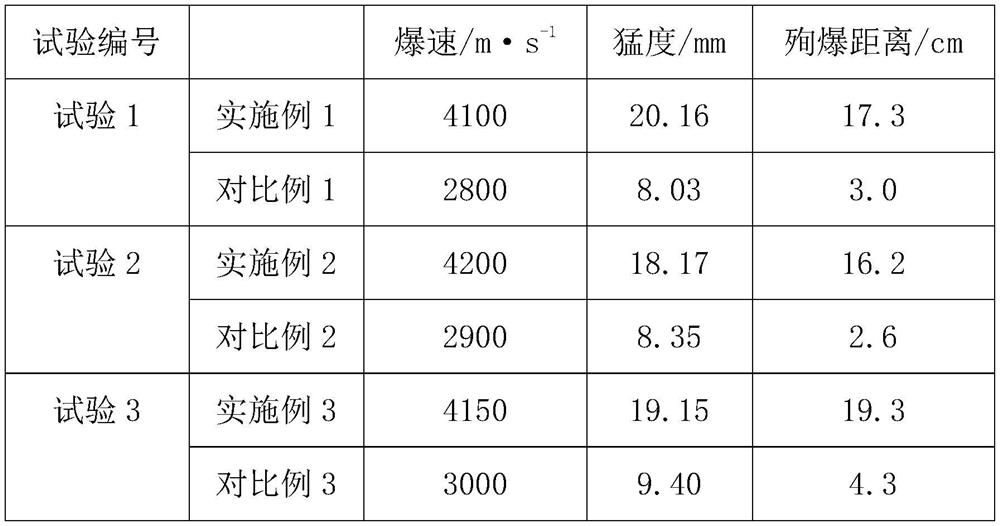

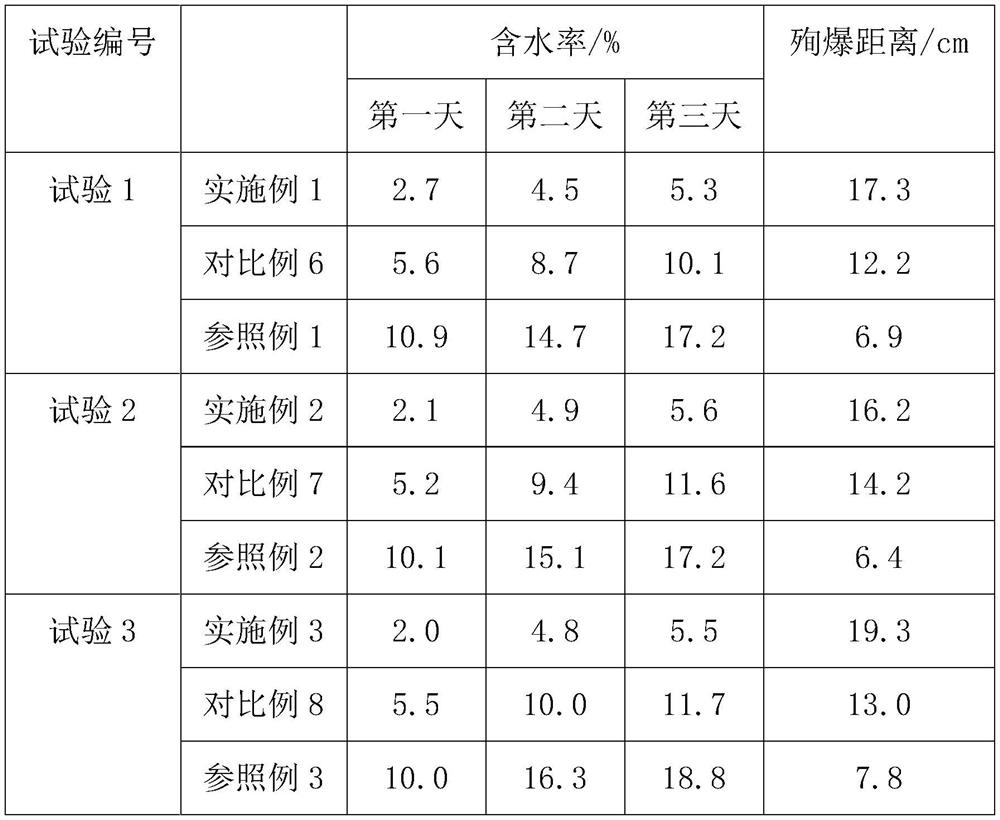

Examples

Embodiment 1

[0023] An environment-friendly emulsion explosive, comprising the following raw materials by mass fraction: 40% ammonium nitrate, 13% sodium nitrate, 3% diesel oil, 5% modified combustible agent, 3% flame suppressant, 2% composite emulsifier, perlite 4%, foaming aid 1%, anti-hydrolysis additive 4%, and water 25%.

Embodiment 2

[0025] An environmentally friendly emulsion explosive, comprising the following raw materials in terms of mass fraction: 41% ammonium nitrate, 14% sodium nitrate, 4% diesel oil, 6% modified combustible agent, 4% flame suppressant, 3% composite emulsifier, perlite 6%, foaming aid 2%, anti-hydrolysis additive 5%, and water 15%.

Embodiment 3

[0027] An environment-friendly emulsion explosive, comprising the following raw materials by mass fraction: 43% ammonium nitrate, 15% sodium nitrate, 5% diesel oil, 7% modified combustible agent, 5% flame suppressant, 4% composite emulsifier, perlite 8%, foaming aid 3%, anti-hydrolysis additive 6% and water 4%.

[0028] Wherein, the composite emulsifier is a mixture of polyisobutenyl succinic anhydride and sorbitan monooleate in a mass ratio of 3:7, wherein the hydroxyl value range of sorbitan monooleate is 220 Between -270; the flame suppressant is made of sodium chloride and potassium chloride in a mass ratio of 4:3;

[0029] The modified combustible is prepared with wood powder as the raw material, nitric acid aqueous solution as the modified solution at a mass ratio of 7:2, wherein the concentration of nitric acid in the nitric acid aqueous solution is 16%-18%; the preparation process of the modified combustible is: Soak the wood powder in nitric acid aqueous solution for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com