Continuous casting intelligent centralized control intelligent application platform construction method

A technology of application platform and construction method, which is applied in the field of continuous casting intelligent centralized control intelligent application platform construction, can solve the problems of low labor efficiency, high labor intensity, frequent production accidents, etc., and achieve reduction of production costs, streamlining of operators, improvement The effect of product quality stability and labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

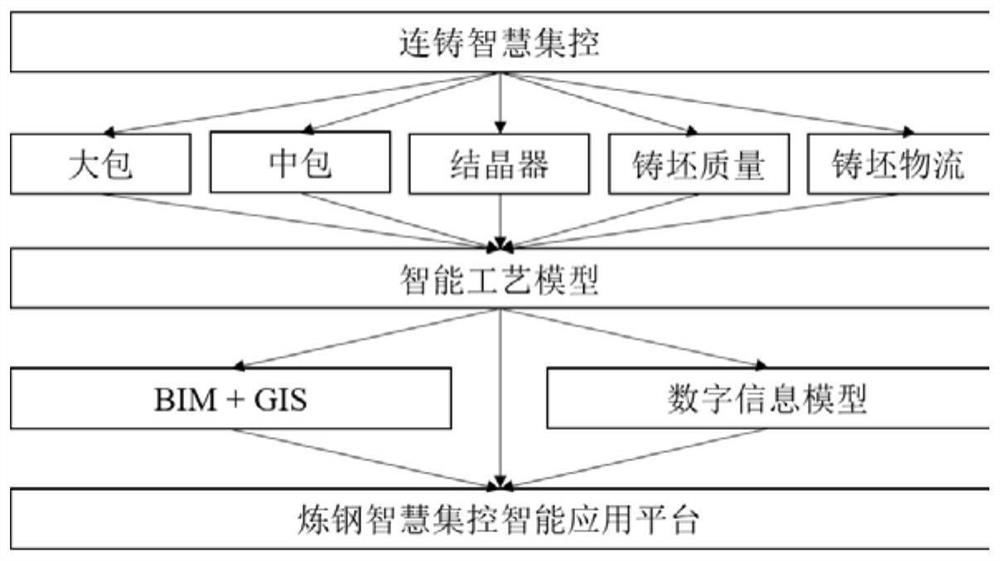

[0022] A construction method of a continuous casting intelligent centralized control intelligent application platform in this embodiment is specifically a construction method of a billet continuous casting intelligent centralized control intelligent application platform with a B / S architecture. Casting machine, its steps are:

[0023] Step 1: According to the continuous casting intelligent centralized control technology plan, the continuous casting process is decomposed into a large-scale intelligent centralized control unit, a medium-sized intelligent centralized control unit, a crystallizer intelligent centralized control unit, a billet quality intelligent centralized control unit, and a casting billet Logistics intelligent centralized control unit;

[0024] Step 2: According to the continuous casting intelligent centralized control technology plan, using the Java programming language, based on metallurgical technology, combined with manual experience, establish automatic te...

Embodiment 2

[0029] The construction method of a continuous casting intelligent centralized control intelligent application platform in this embodiment is specifically a construction method of a slab continuous casting intelligent centralized control intelligent application platform with a C / S architecture. Slab continuous casting machine, the steps are:

[0030] Step 1: According to the continuous casting intelligent centralized control technology plan, the continuous casting process is decomposed into a large-scale intelligent centralized control unit, a medium-sized intelligent centralized control unit, a crystallizer intelligent centralized control unit, a billet quality intelligent centralized control unit, and a casting billet Logistics intelligent centralized control unit;

[0031] Step 2: According to the continuous casting intelligent centralized control technology plan, use C, C++, C# programming language, based on metallurgical technology, combined with manual experience, establ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com