Phenyl-modified PDMS separation membrane, preparation method and application of phenyl-modified PDMS separation membrane in aromatic compound separation

A technology for separating membranes and compounds, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low permeation flux, low selective separation, etc., to avoid entanglement, improve spacing, and improve separation selection. Effects of sex and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

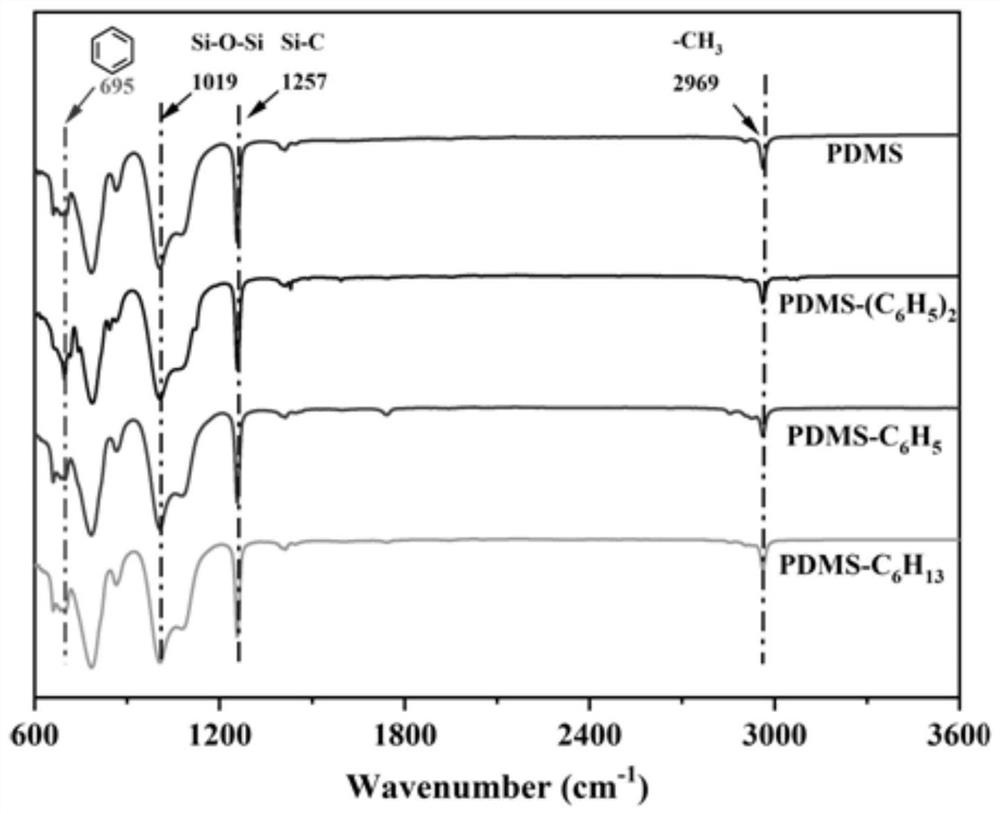

[0047] The consistent mobility between the main chain and the side chain groups leads to the stacking of PDMS segments in a highly entangled structure. PDMS membranes used for membrane separation usually require tetraethylorthosilicate as a cross-linking agent for curing.

[0048] The synthetic route of the present embodiment is as follows:

[0049]

[0050] The preparation method is:

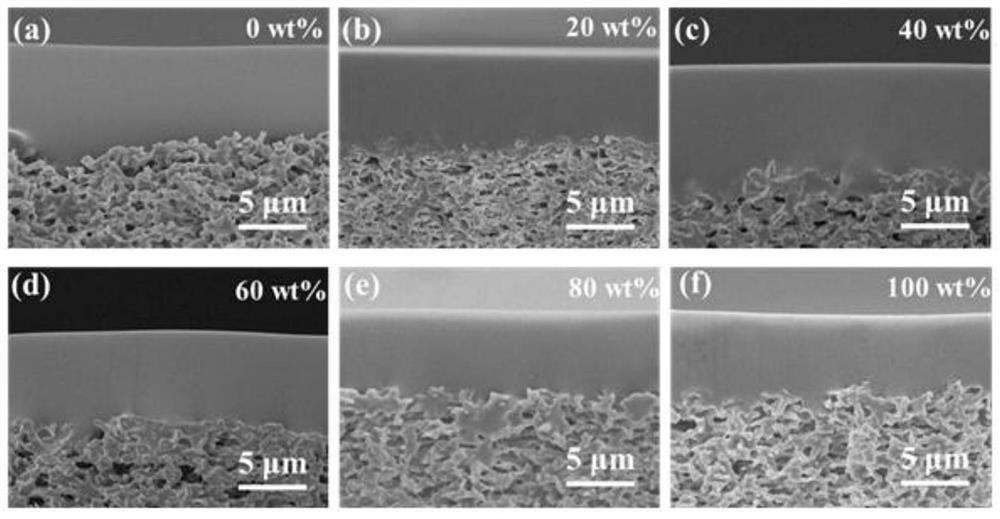

[0051] A certain amount of hydroxyl-terminated PDMS-(C 6 h 5 ) 2 Dissolve in n-heptane to make a 10 wt% polymer solution. The casting liquid is crosslinked by using the crosslinking agent tetraethyl orthosilicate and the catalyst dibutyltin dilaurate, wherein the polymer: crosslinking agent: catalyst = 100:10:1 (mass ratio). When the casting solution reaches a suitable viscosity, use a scraper to scrape and coat the porous PVDF support to form a film. The prepared composite film was evaporated at room temperature for 24 hours, and then thermally cross-linked at 70° C. for 12 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com