Annular multi-wall layer structure bionic cutter based on bamboo fiber cell walls and preparation method thereof

A bionic tool and cell wall technology, applied in coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problem of inability to balance wear resistance and toughness, achieve good physical and mechanical properties, and improve comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

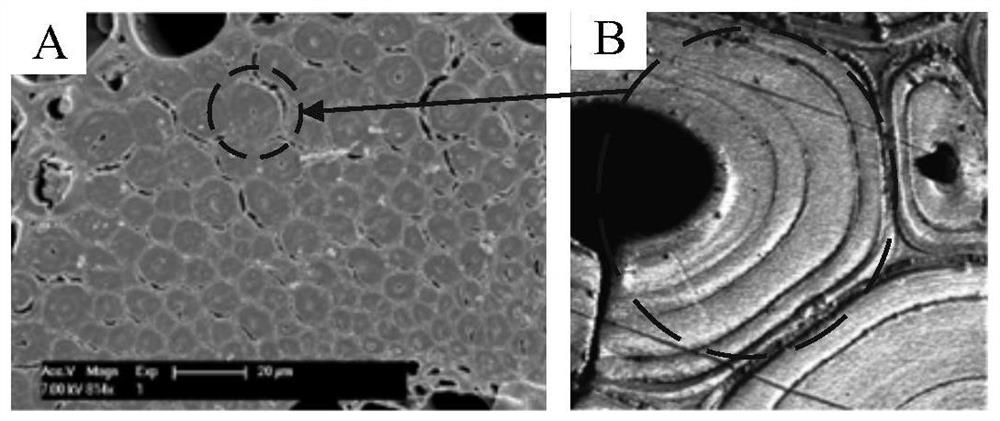

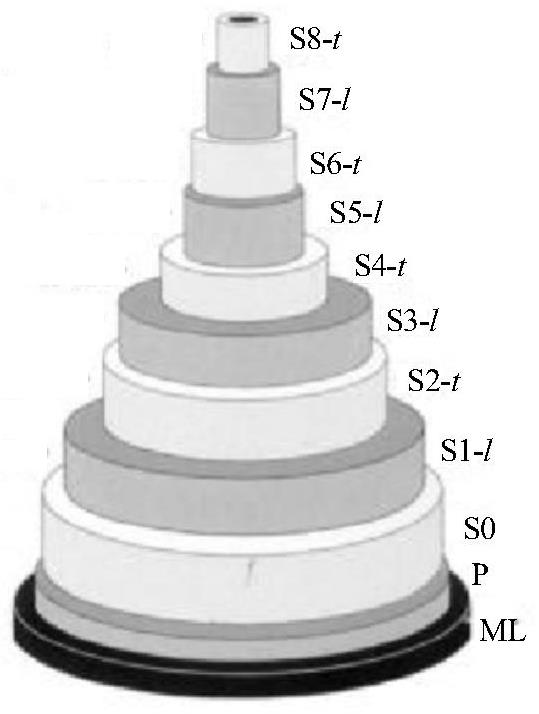

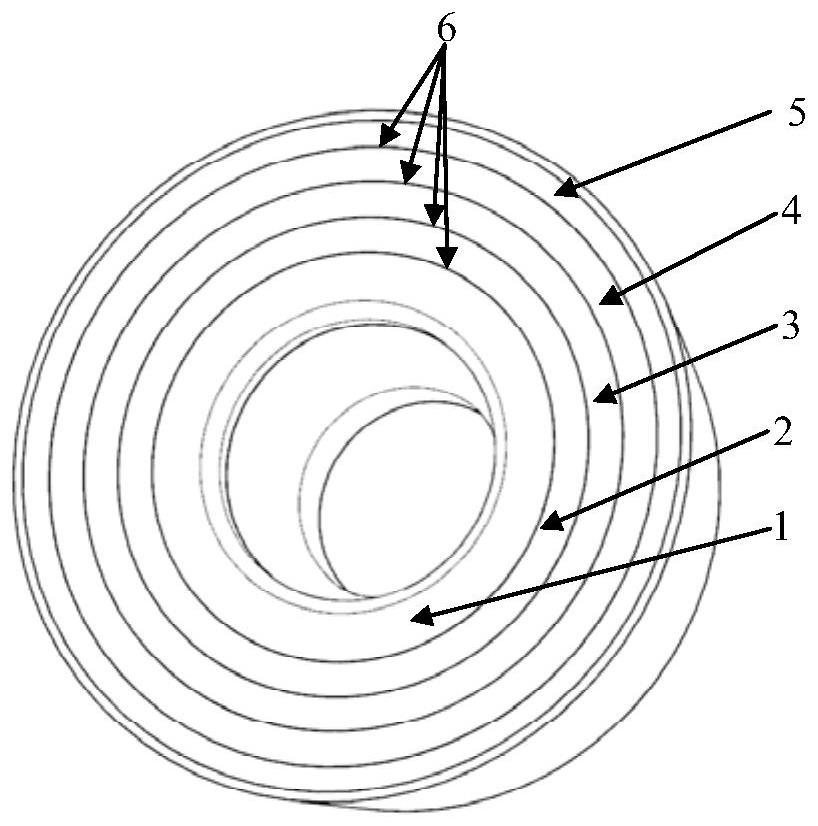

[0039] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, the bionic cutter based on the bamboo fiber cell wall annular multi-wall structure described in this embodiment includes a cutter body, the shape of the cutter body is a ring, and the cutter body includes an inner layer 1, a second layer that are sequentially fixed from the inside to the outside. A transition layer 2, a second transition layer 3, a third transition layer 4 and an outer wear-resistant layer 5;

[0040] The materials of the inner layer 1, the first transition layer 2, the second transition layer 3, the third transition layer 4 and the outer wear-resistant layer 5 are all WC-Co cemented carbide, and the mass percentage of WC in the inner layer 1 is Higher than the mass percentage of WC in the first transition layer 2, the second transition layer 3 and the third transition layer 4 and lower than the mass percentage of WC in the outer wear-resistant layer 5, the mass pe...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, the mass percentage of Co in the inner layer 1 of this embodiment is 10%, the mass percentage of Co in the first transition layer 2 is 16%, and the mass percentage of Co in the second transition layer 3 is Co content is 14%, the mass percentage content of Co in the third transition layer 4 is 12%, and the mass percentage content of Co in the outer wear-resistant layer 5 is 5%. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0046] The tool body is made of WC-Co cemented carbide, and the contents of WC and Co are different in each part. Because the outer wear-resistant layer will have good wear resistance, the WC content is higher in this layer and the Co content is lower, and the Co content is 5%, so as to improve the wear resistance of the bionic tool; the first transition layer, the second The transition layer and ...

specific Embodiment approach 3

[0047] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the surfaces of the inner layer 1 , the first transition layer 2 , the second transition layer 3 , the third transition layer 4 and the outer wear-resistant layer 5 in this embodiment are all coated with adhesive. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0048] Specific implementation mode four: combination Figure 1 to Figure 4 To describe this embodiment, the material of the binder 6 in this embodiment is metal Co. The undisclosed technical features in this embodiment are the same as those in the third embodiment. Here the metal Co acts as a binder between each layer during sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com