Glue adhesive film as well as preparation method and application thereof

A technology for sticking films and adhesives, which is applied in the application field of sticking films. It can solve the problems of large solid particle size, reduced glue property, degumming, etc., and achieves high peeling force and cohesion performance, and good zero initial adhesion effect. , excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

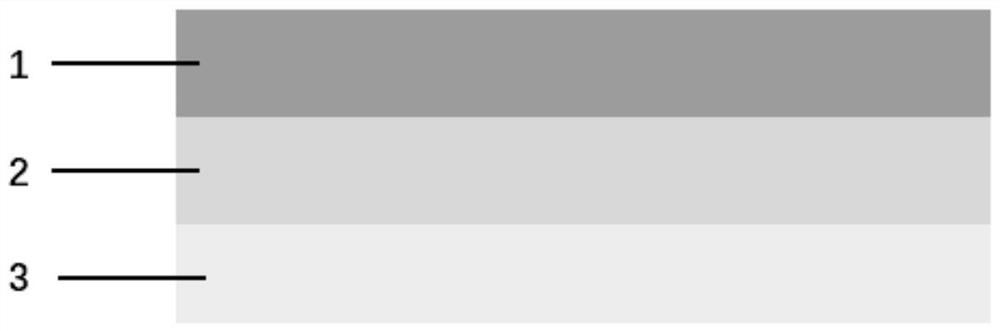

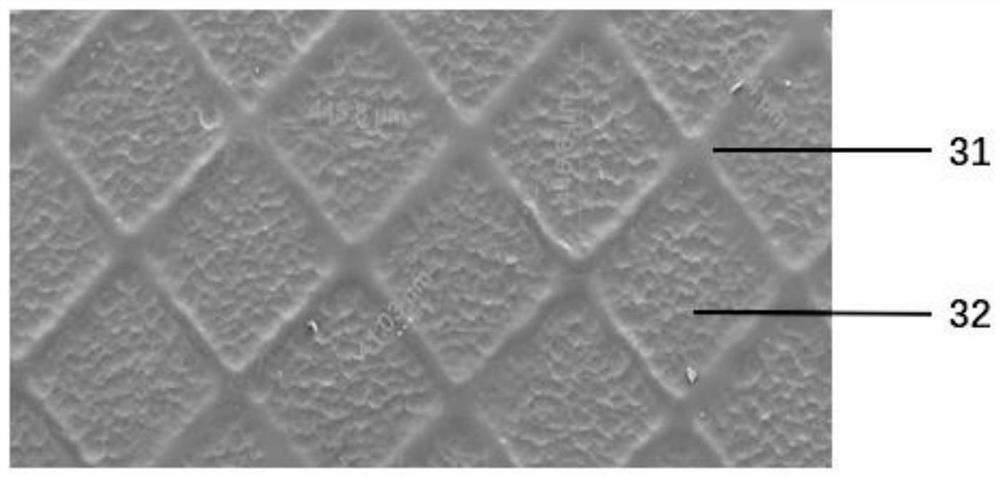

[0057] (5) Preparation of frosted grid release layer: on the surface of the release base material, such as the surface of the PET film, carry out atomization and embossing treatment and then apply the release agent to form the release surface;

[0058] (6) Adhesive film preparation: The side of the adhesive layer having the solid particles in a semi-bare state is bonded to the release surface of the frosted grid release layer to obtain an adhesive film.

[0059] Preferably, the coating can be performed using comma blade coating equipment, and the drying can be performed in an oven under suitable conditions. The release surface can have a regular rhombus structure.

[0060] The adhesive film of the invention can be widely used in advertising, decoration and other aspects.

[0061] The method for preparing frosted grid release layer 3 of the present invention may comprise the following steps:

[0062] (1) Film or paper substrates such as PET, PE, PP, etc. are PE-coated and sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diagonal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com