Manufacturing method of antibacterial PET fabric containing modified nano-zinc oxide

A technology of nano-zinc oxide and a manufacturing method, which is applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., can solve the problems of low binding fastness of antibacterial agent and fabric, poor dispersibility of antibacterial agent, and large amount of antibacterial agent, etc. Achieve the effect of improving bond fastness, improving washability, and solving cohesion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Add 0.208g of ethyl glycolate, 0.494g of propyltriethoxysilane isocyanate, and 0.0034ml of dibutyltin dilaurate into a glass bottle, and stir in a water bath at 40°C for 6h. Add the product into a three-neck flask containing nano-zinc oxide ethanol aqueous solution, in which ethanol 135mL, water 65mL, zinc oxide 2g, and stir at 60°C for 12h. The product is filtered and washed with ethanol, dried and ground to obtain modified nano-zinc oxide powder.

example 2

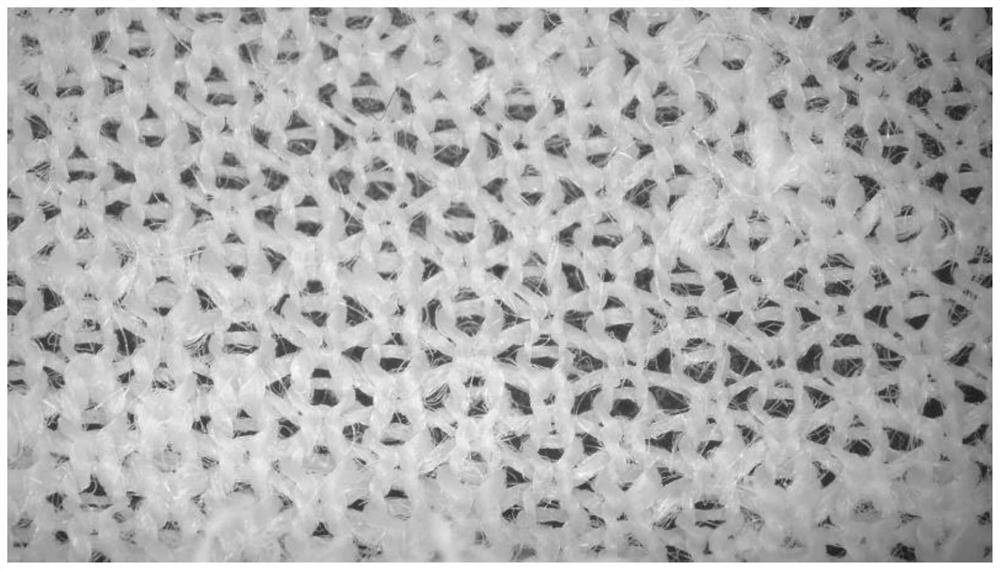

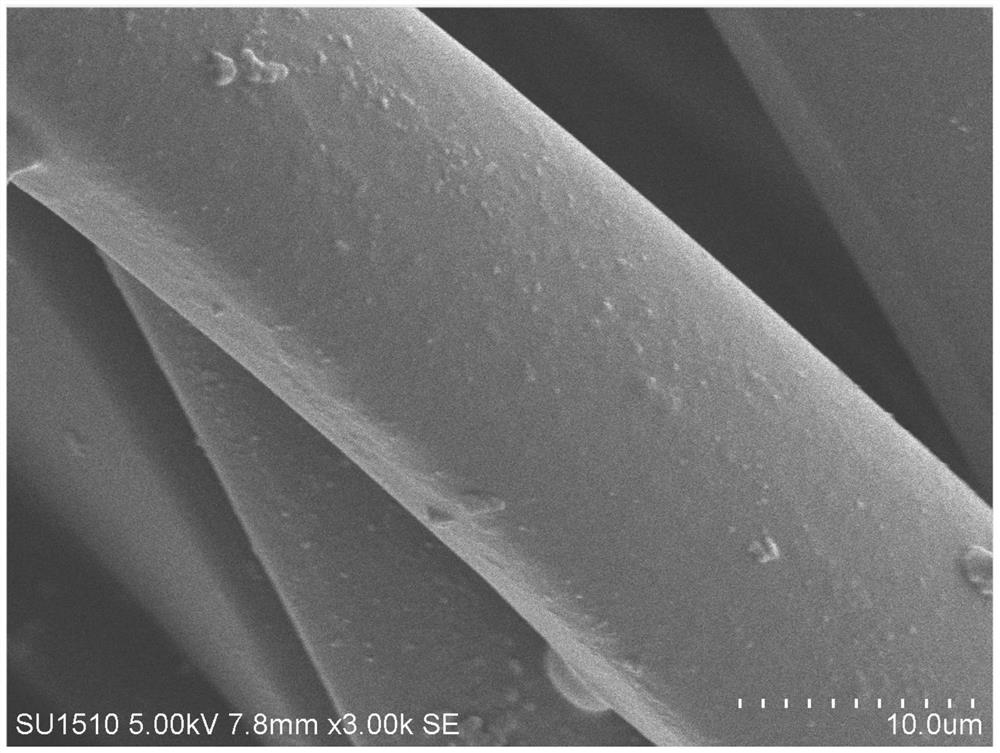

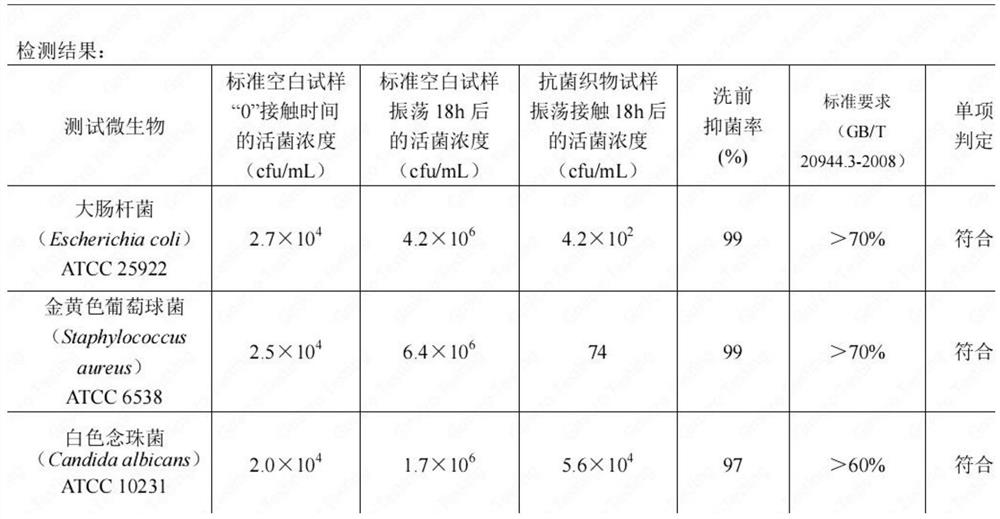

[0029] Weigh 0.1g of modified nano-zinc oxide powder and place it in 100mL of distilled water for ultrasonic dispersion for 1h, pour the obtained nano-zinc oxide aqueous dispersion into the dyeing cup of the high-temperature and high-pressure dyeing machine, add 2g of polyester fabric at the same time, and heat the fabric under high temperature. For high-pressure dipping, heat up to 75°C at a rate of 2°C / min; then raise the temperature to 125-135°C at a rate of 1°C / min and keep warm for 30 minutes at 3 atmospheres; finally, lower the temperature of the dyeing cup to room temperature . Take out the loaded fabric, wash it in cold water, and dry it to get the final antibacterial PET fabric, its structure and diffusion effect are as follows figure 1 and 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com