Bridge structure mass concrete intelligent temperature control system and method

A large-volume concrete and intelligent temperature control technology, applied in control/regulation systems, bridges, temperature control, etc., can solve the problems that large-volume concrete cannot be used in bridge structures, does not consider the load of steel bars, and limited construction sites, etc., to improve Scalability and working stability, flexible on-site installation and mobile construction, and the effect of reducing the size of the cabinet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, the present invention is described in more detail to facilitate understanding of the present invention.

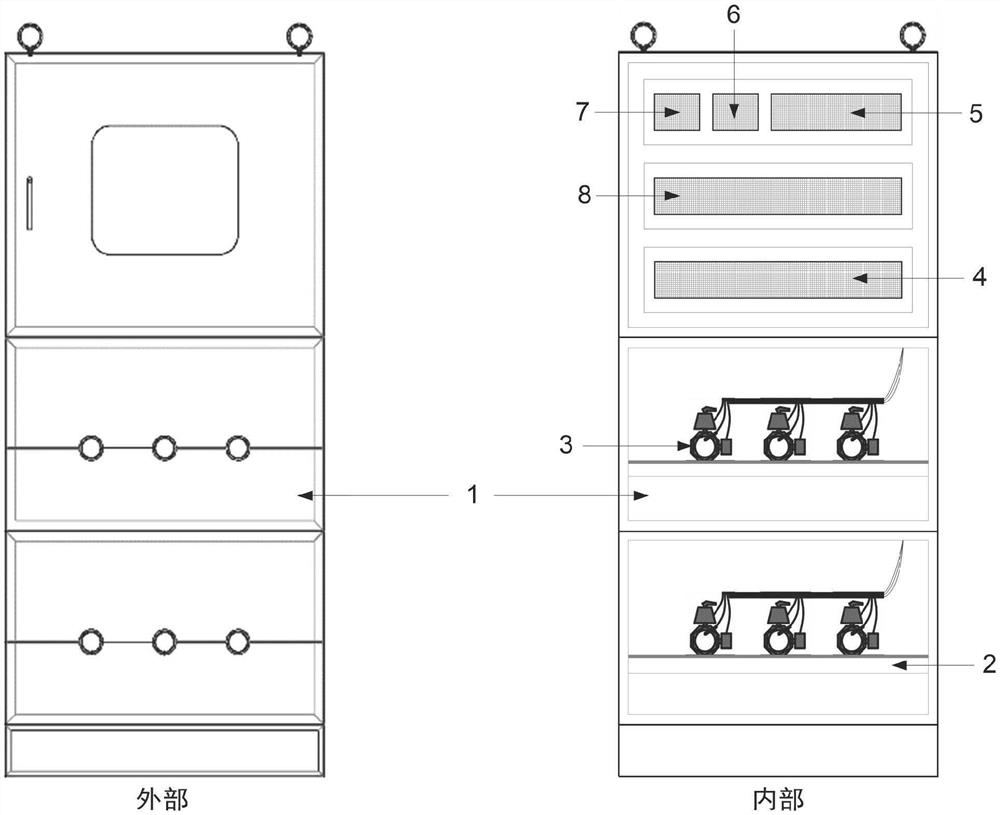

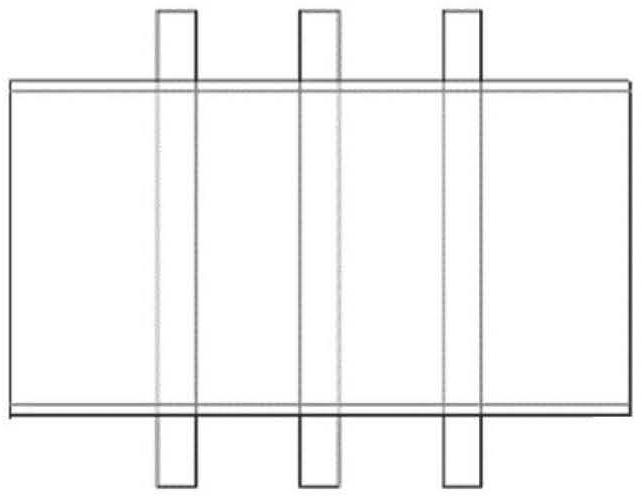

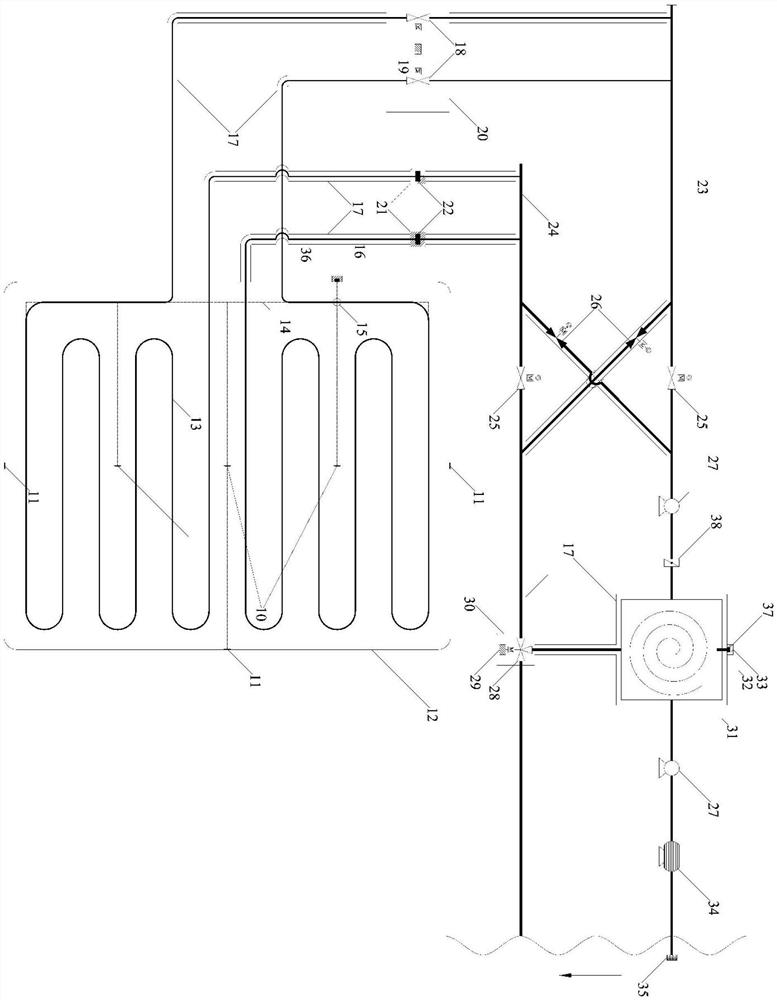

[0044] Such as image 3 As shown, the large-volume concrete intelligent temperature control system for bridge structures according to the present invention includes a water supply system, a water return system, a water flow reversing system, an integrated intelligent temperature control cabinet 20, a cooling water pipe 13 pre-buried in the concrete of the pouring warehouse 12, Concrete internal thermometer 10 and surface thermometer 11; described bridge structure mass concrete intelligent temperature control system adopts river deep river water near bridge structure as cooling water; described water supply system includes water supply main pipe 23 and the water tank 31 that is arranged on the water supply main pipe and Water supply pump 34. In the water supply system, river water is pumped into the water tank 31 by the water supply pump 34. When the hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com