Remote grinding database management system of user-foundation-process-knowledge progressive structure and efficient low-consumption intelligent grinding method

A management system and database technology, applied in the field of intelligent processing methods, can solve problems such as high processing energy consumption, frequent grinding burns, and inability to deal with them uniformly, and achieve efficient management and classification, good economic and social benefits, and convenient query effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

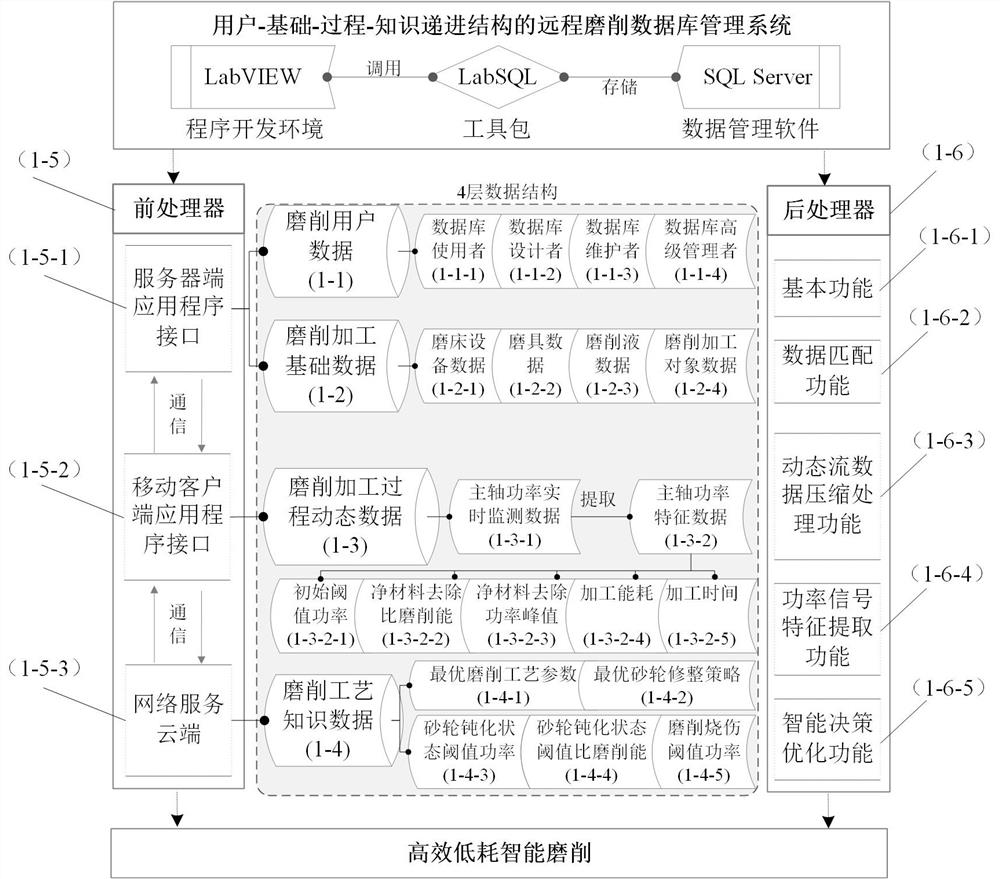

[0031] Specific implementation mode one: combined with figure 1 , detailing a remote grinding database management system with user-basic-process-knowledge progressive structure, the top layer of the remote grinding database management system with user-basic-process-knowledge progressive The pre-processor (1-5) and post-processor (1-6) of the grinding database management system use the data management software SQL Server to manage the underlying grinding user data (1-1), grinding basic data (1- 2) The dynamic data (1-3) of the grinding process and the knowledge data (1-4) of the grinding process. The interface between the program development environment LabVIEW and the data management software SQL Server is realized through the LabVIEW open software toolkit LabSQL.

[0032]The underlying data of the remote grinding database management system of the user-basic-process-knowledge progressive structure includes a four-layer progressive data management structure, the first layer of ...

specific Embodiment approach 2

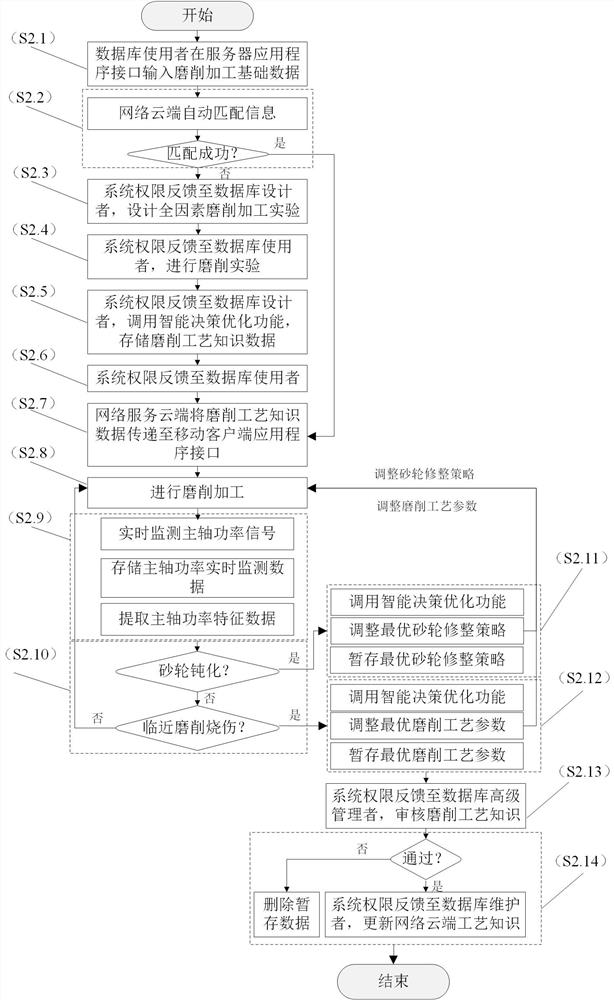

[0034] Specific implementation mode two: combined with attached figure 2 , specifying a high-efficiency and low-cost intelligent grinding method using a remote grinding database management system with a user-base-process-knowledge progressive structure, including the following steps:

[0035] Step 1 (S2.1): The database user (1-1-1) enters the basic grinding data (1-2) in the server application program interface (1-5-1);

[0036] Step 2 (S2.2): Call the data matching function (1-6-2), and automatically compare the most suitable grinding object data (1-2-4) in the network service cloud (1-5-3). Optimal grinding process parameters (1-4-1) and optimal grinding wheel dressing strategy (1-4-2), if the information matching fails, jump to step 3 (S2.3), if the information matching is successful, jump to Step 7 (S2.7);

[0037] Step 3 (S2.3): The remote grinding database management system feeds back the system authority to the database designer (1-1-2) to design the experimental sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com