Immersed liquid cooling heat dissipation module and heat dissipation method

A liquid-cooled heat dissipation and immersion technology, applied to electrochemical generators, electrical components, circuits, etc., can solve the problems of increasing the risk of arc and common mode interference, flashover along the surface, safety accidents, etc., to improve heat exchange and cooling efficiency , improve heat dissipation capacity, and prevent fire risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

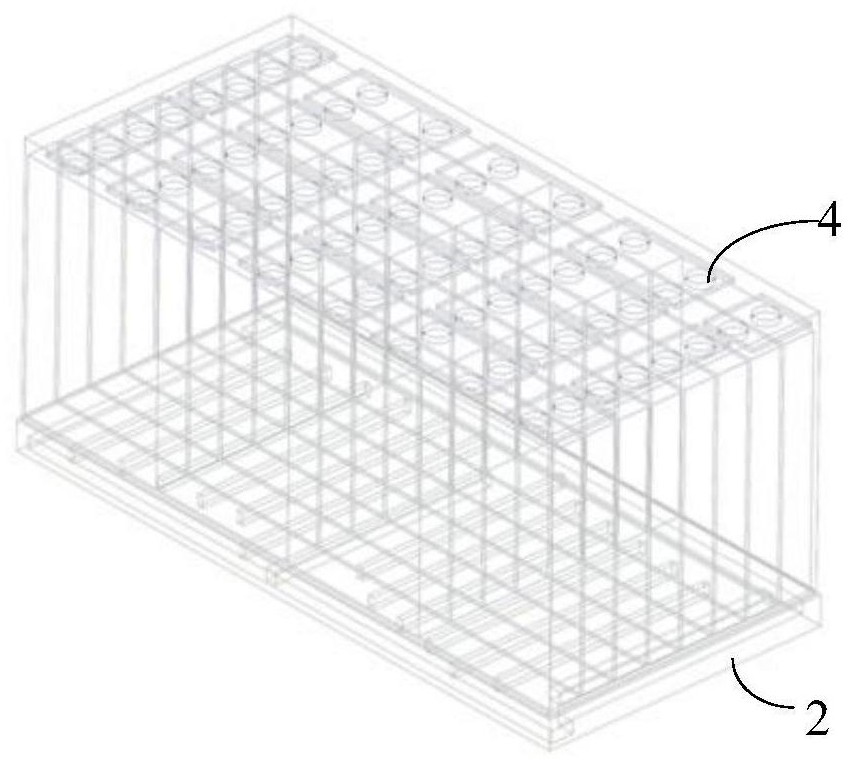

[0044] In this heat dissipation module, a 60Ah lithium iron phosphate battery is selected and grouped by 2 parallel 16 strings. For the arrangement of temperature detectors, a temperature sensor is arranged at the negative pole ear of each 2 parallel batteries. The distance between the battery in the direction of the maximum contact surface is 3mm, the distance between the battery and the outer wall of the module is 5mm, and the shortest distance from the top of the module to the battery connection piece is 10mm. The direct contact cooling liquid used is fluorinated liquid, and the dosage is 5L, the cooling used is water-ethylene glycol solution, and the inlet flow rate is 1.5L / min.

[0045] Bring the measured battery heating power data into the Fluent software, set the initial temperature of the environment at 18°C, and after 6 cycles, from Figure 5 It can be seen that the average temperature of the batteries in the battery module is about 26°C, and the battery with the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com