Preparation method of polymer waterproof cement-based cloth composite hard polyurethane insulation board

A rigid polyurethane and waterproof technology, applied in cement coatings, chemical instruments and methods, mining equipment, etc., can solve the problems of short service life, loss of thermal insulation effect, easy damage of thermal insulation boards, etc., to increase surface strength and maintain breathing The effects of breathability and high freeze-thaw stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

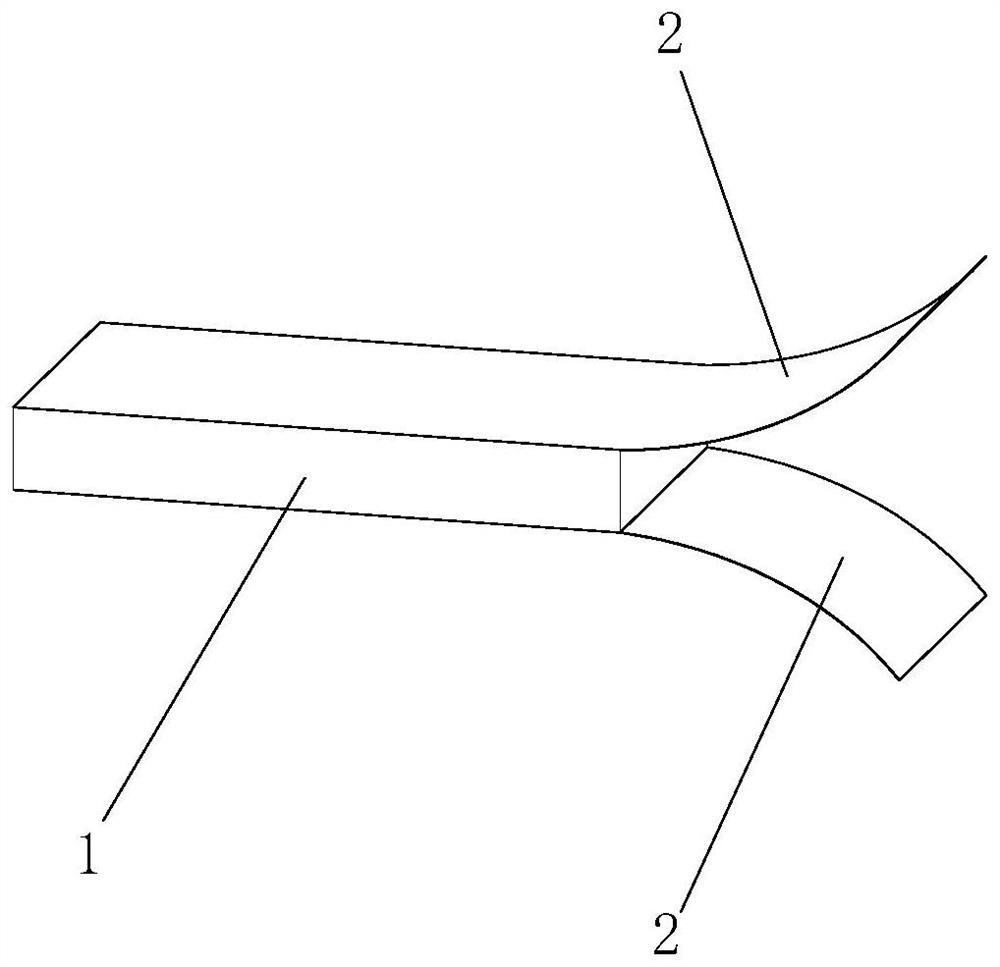

[0021] Such as figure 1 A polymer waterproof cement-based cloth composite rigid polyurethane insulation board is shown, which includes a polyurethane insulation board 1 and a polymer waterproof cement-based cloth 2 located on its upper and lower surfaces, and the above-mentioned polymer waterproof cement-based cloth composite The preparation method of rigid polyurethane insulation board specifically comprises the following steps:

[0022] (1) Inject the polymer waterproof cement mortar into the cement slurry pool, vibrate the cement mortar, spread the cement mortar evenly on the conveyor belt, and continuously push the conveyor belt covered with cement mortar by traction, and the alkali-free glass fiber net The grid cloth is pressed on a conveyor belt cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com