Environment-friendly concrete release agent and preparation method thereof

An environment-friendly concrete and release agent technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of inability to eliminate concrete pores, limited concrete demoulding effect, inability to eliminate hole structure, etc. and durability, reducing environmental pollution and human harm, and reducing the number of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

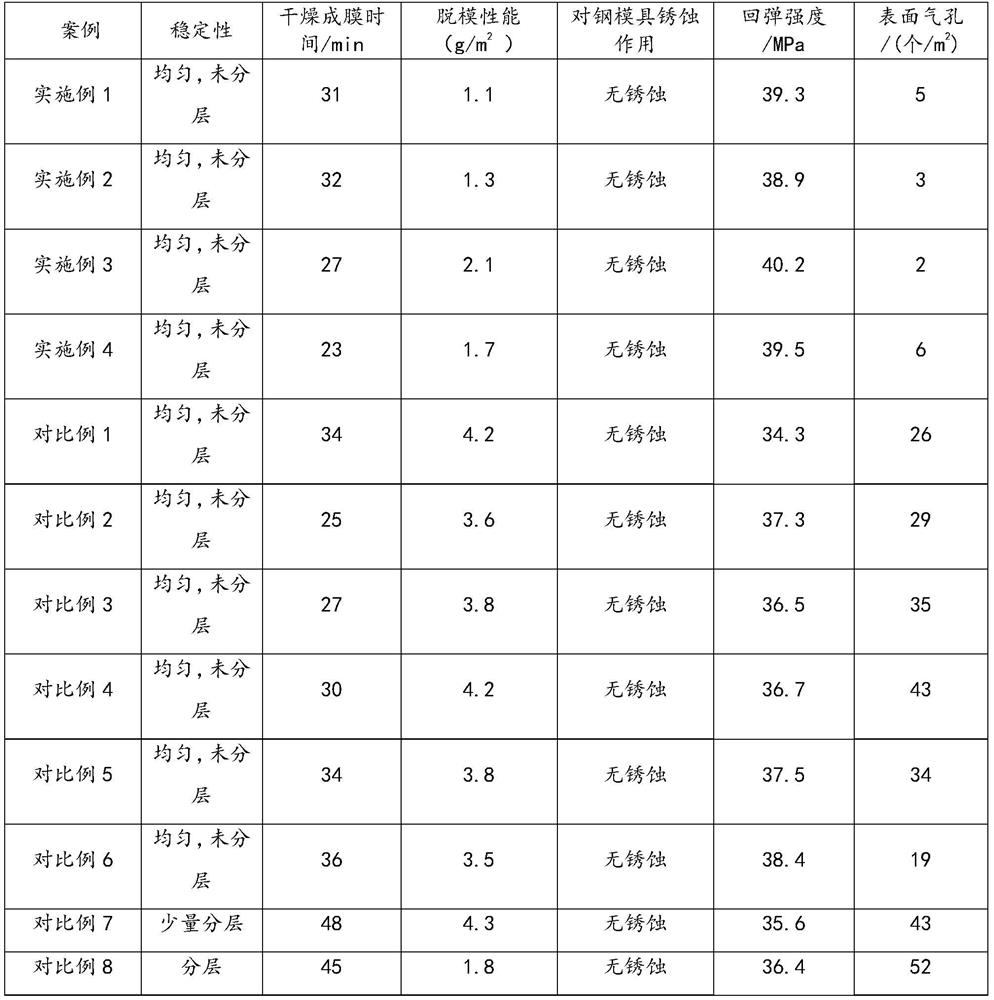

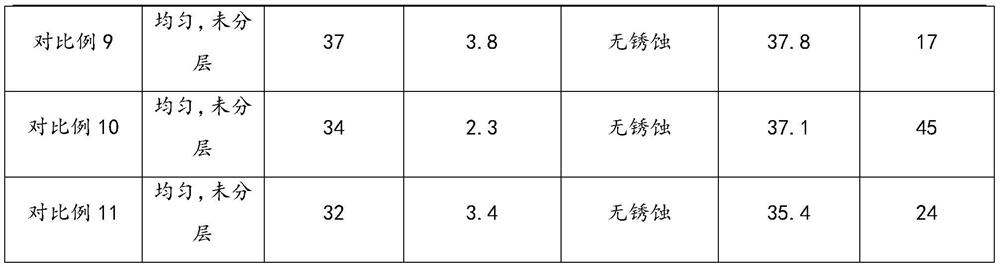

Examples

Embodiment 1

[0038] Add 3 parts of polyethylene glycol oleate (PEG400DO) and 3 parts of sodium stearate into the stirring container, then add 20 parts of water, and heat up to 50°C while stirring to form emulsified water for later use.

[0039] Mix 3 parts of dioctyl maleate sodium sulfonate, 10 parts of 24-degree palm oil and 4 parts of sorbitan fatty acid ester (S-80), heat up to 50°C, stir well and add 1 part of MARLOX BR3551, made into a microemulsion mixture;

[0040] Then slowly add 6 parts of emulsified water to the microemulsion mixture, heat up to 50°C while stirring, stir until the emulsion turns milky white, stop adding emulsified water, increase the speed to 1000r / min, stir for 30min, and then cool to 30 ℃, and then 1 part of sodium benzoate, 0.1 part of potassium sorbate and the remaining 20 parts of emulsified water, and continue to stir for 15 minutes to obtain the environmentally friendly concrete release agent.

Embodiment 2

[0042] Add 2 parts of polyethylene glycol oleate (PEG400MO) and 2 parts of sodium lauryl sulfate into the stirring container, then add 40 parts of water, and heat up to 60°C while stirring to form emulsified water for later use.

[0043] Mix 2 parts of dioctyl maleate sodium sulfonate, 30 parts of palm oil at 44 degrees and 10 parts of sorbitan fatty acid ester (S-85), heat up to 60°C, stir well and add 2 parts of MARLOX BR3551 to make a microemulsion mixture;

[0044] Slowly add 14 parts of emulsified water to the microemulsion mixture, heat up to 45°C while stirring, stir until the emulsion turns milky white, stop adding emulsified water, increase the speed to 1000r / min, stir for 30min, and then cool to 30°C Next, 0.1 part of sodium benzoate, 0.5 part of potassium sorbate and the remaining 30 parts of emulsified water were stirred for 20 minutes to obtain the environmentally friendly concrete release agent.

Embodiment 3

[0046] Add 10 parts of polyethylene glycol oleate (PEG600DO) and 10 parts of sodium dodecylbenzenesulfonate into the stirring container, then add 60 parts of water, and heat up to 60°C while stirring to form emulsified water for later use.

[0047] Mix 1 part of dioctyl maleate sodium sulfonate, 60 parts of 52-degree palm oil and 10 parts of sorbitan fatty acid ester (S-40), heat up to 55°C, stir well and add 3 parts of MARLOX BR3551 to make a microemulsion mixture;

[0048] Slowly add 25 parts of emulsified water to the microemulsion mixture, heat up to 55°C while stirring, stir until the emulsion turns milky white, stop adding emulsified water, increase the speed to 1000r / min, stir for 30min, and then cool to 30°C , and then 2 parts of sodium benzoate, 1 part of potassium sorbate and the remaining 55 parts of emulsified water were stirred for 25 minutes to obtain the environmentally friendly concrete release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com