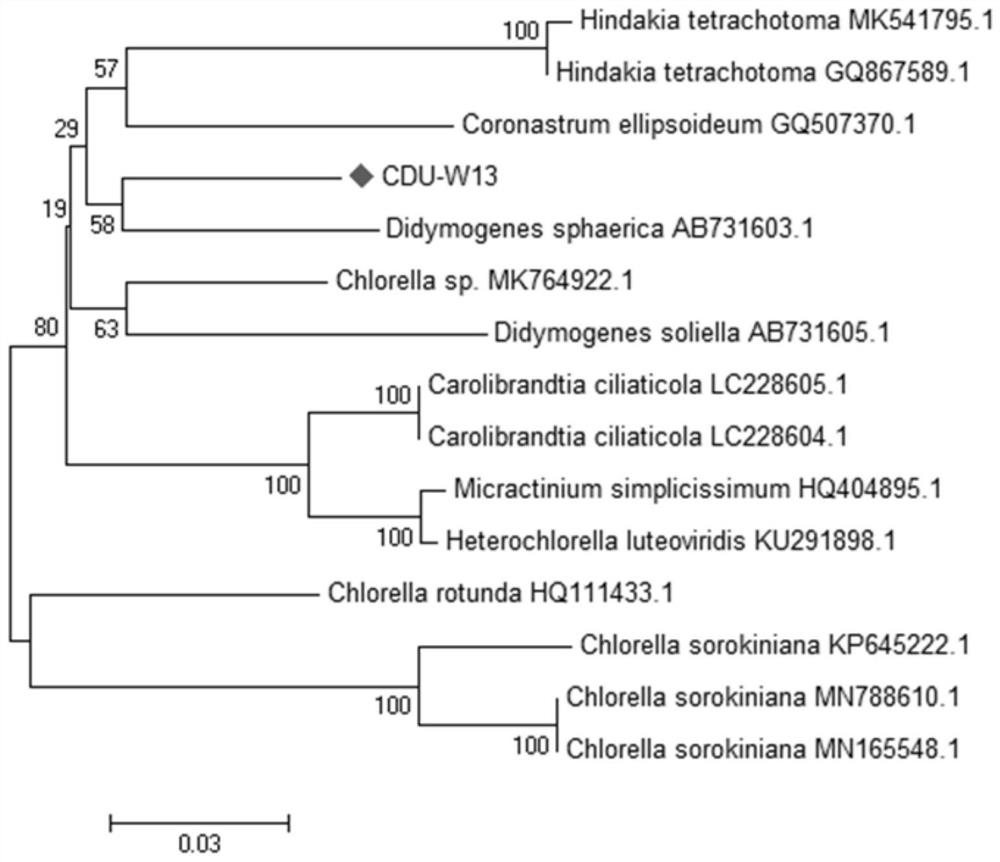

Novel freshwater oil-producing microalgae species as well as culture method and application thereof

A cultivation method and aquatic technology, applied in the field of new freshwater oil-producing microalgae species and their cultivation, can solve the problems of large footprint, damage to the economy of microalgae energy production, high investment costs, etc., and achieve the goal of reducing cultivation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

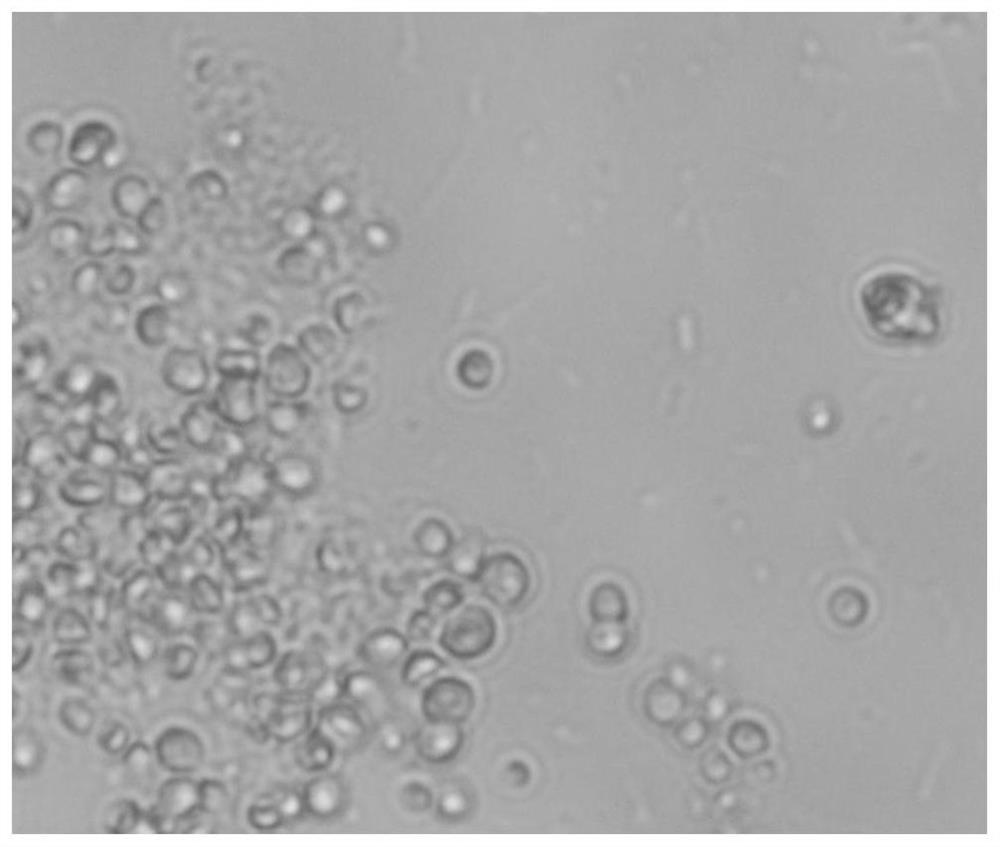

Embodiment 1

[0047] The algae cells were inoculated in BBM medium and cultured in a constant temperature and constant light incubator for 20 days. The culture conditions were: continuous light, and the light intensity was 100 μmol photons m -2 the s -1 , the temperature is 25°C. The results of algae culture were as follows: figure 2 shown.

Embodiment 2

[0049] The algae cells were inoculated in the BBM mixed medium containing 5wt% rice washing water, and cultivated in a constant temperature and constant light incubator for 20 days. The culture conditions were: continuous light, and the light intensity was 150 μmol photons m -2 the s -1 , the temperature is 20°C.

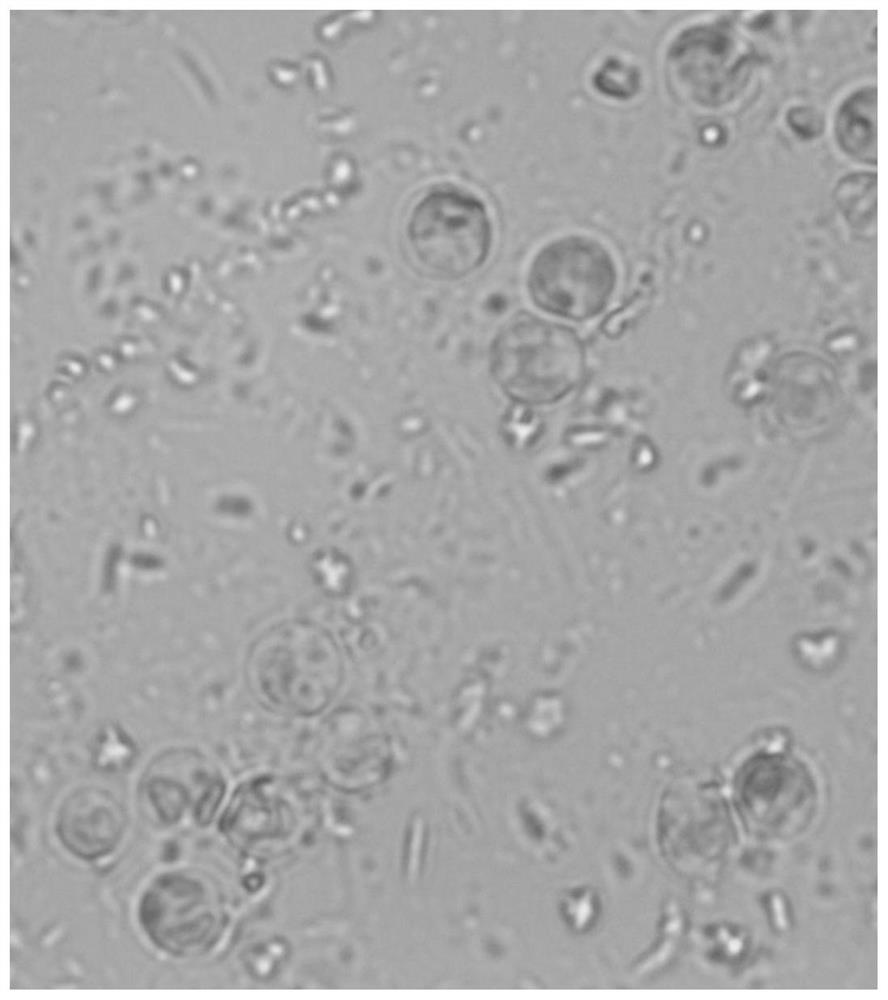

Embodiment 3

[0051] The algae cells were inoculated in the BBM mixed medium containing 10wt% rice washing water, and cultivated in a constant temperature and constant light incubator for 20 days. The culture conditions were: continuous light, and the light intensity was 100 μmol photons m -2 the s -1 , the temperature is 25°C. The results of algae culture image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com