Photoelectric composite waterproof flame-retardant cable for photovoltaic system and processing equipment of photoelectric composite waterproof flame-retardant cable

A photoelectric composite and photovoltaic system technology, applied to power cables including optical transmission components, power cables with shielding layer/conductive layer, power cables, etc., can solve the problem of lack of cable processing equipment, difficulty in ensuring cable strength, waterproof and flame retardant Performance and anti-electromagnetic shielding performance, etc., to achieve good strength, increase strength, and improve current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

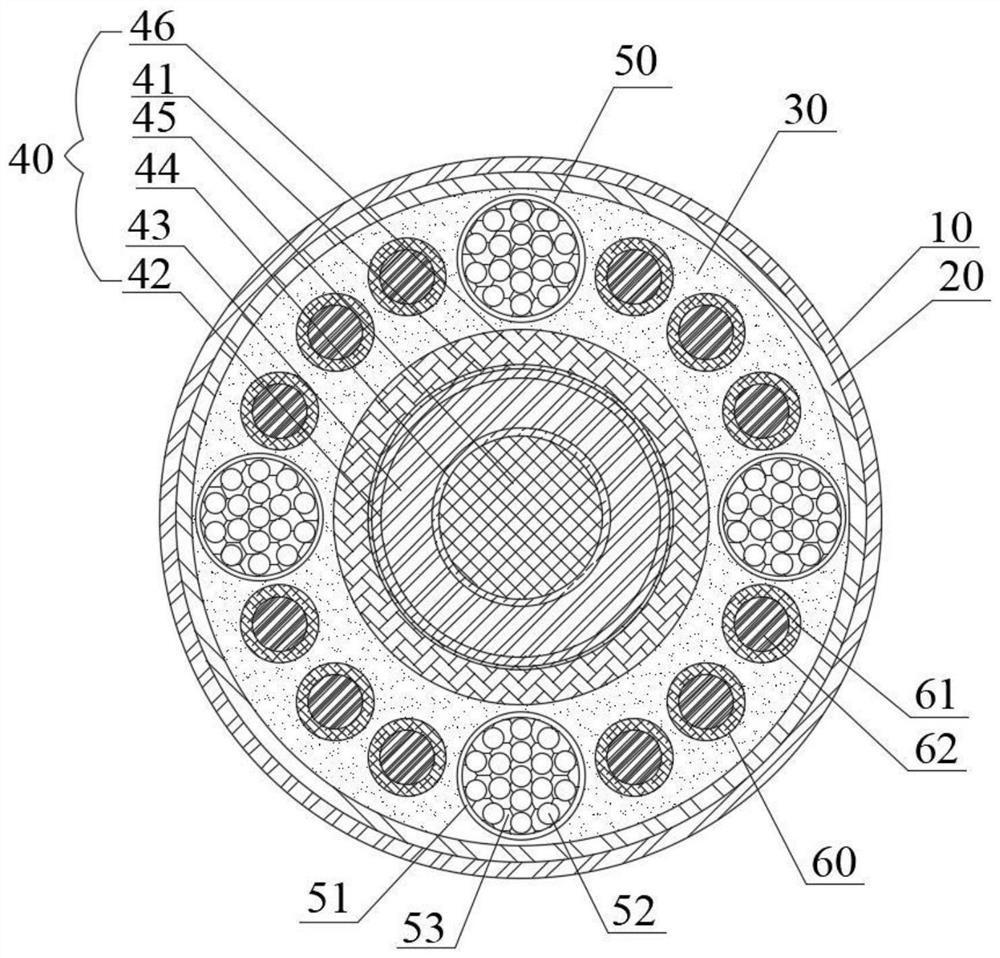

[0033] Such as figure 1 As shown, this embodiment provides a photoelectric composite waterproof and flame-retardant cable for photovoltaic systems, including a waterproof outer sheath layer 10, an anti-corrosion stainless steel tape armor layer 20, and a waterproof and flame-retardant filling layer 30 arranged in sequence from outside to inside 1. Electric transmission unit 40, several optical transmission units 50 are distributed in annular array in waterproof and flame-retardant filling layer 30; electric transmission unit 40 includes water-blocking tape layer 46, metal shielding layer 41, insulating shielding layer arranged in sequence from outside to inside 42 , insulation layer 43 , conductor shielding layer 44 , conductor 45 ; a plurality of reinforcements 60 are provided between adjacent light transmission units 50 in the waterproof and flame-retardant filling layer 30 .

[0034] The optical transmission unit 50 includes a loose tube 51 arranged on the periphery, and a ...

Embodiment 2

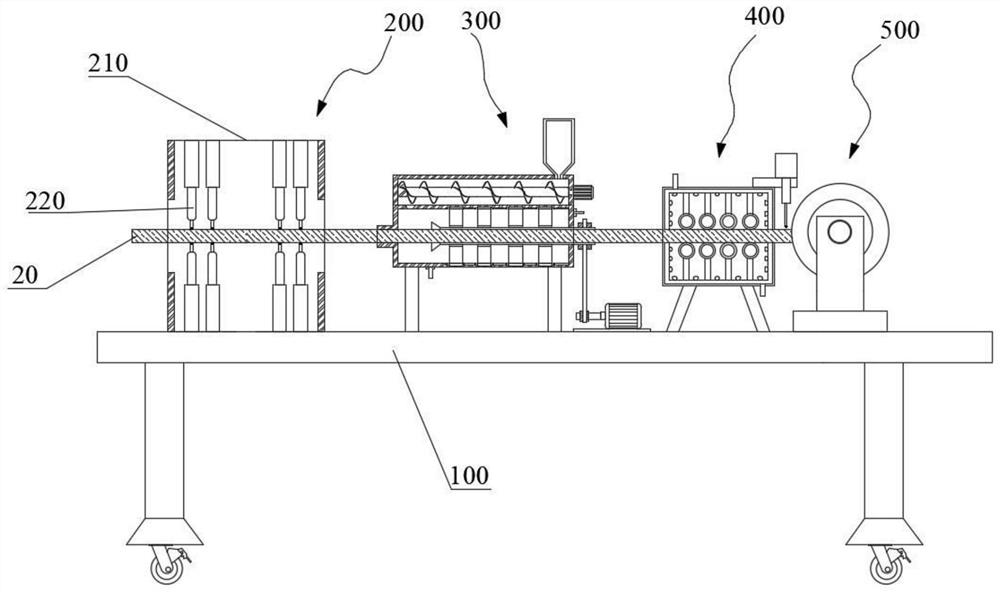

[0038] Such as Figure 1-2 As shown, this embodiment provides a processing equipment for a photoelectric composite waterproof and flame-retardant cable used in a photovoltaic system, which is used to extrude the periphery of the anti-corrosion stainless steel tape armor layer 20 of the photoelectric composite waterproof and flame-retardant cable in Example 1 to obtain waterproof The outer sheath layer 10 has the functions of conveying, extruding, shaping and pressing, winding and cutting the anti-corrosion stainless steel tape armor layer 20 to obtain a photoelectric composite waterproof flame-retardant cable with a waterproof outer sheath layer 10 . Specifically, the processing equipment includes a frame 100, on which a transport mechanism 200, a packaging mechanism 300, a shaping mechanism 400, and a winding and cutting mechanism 500 are sequentially arranged from one side to the other.

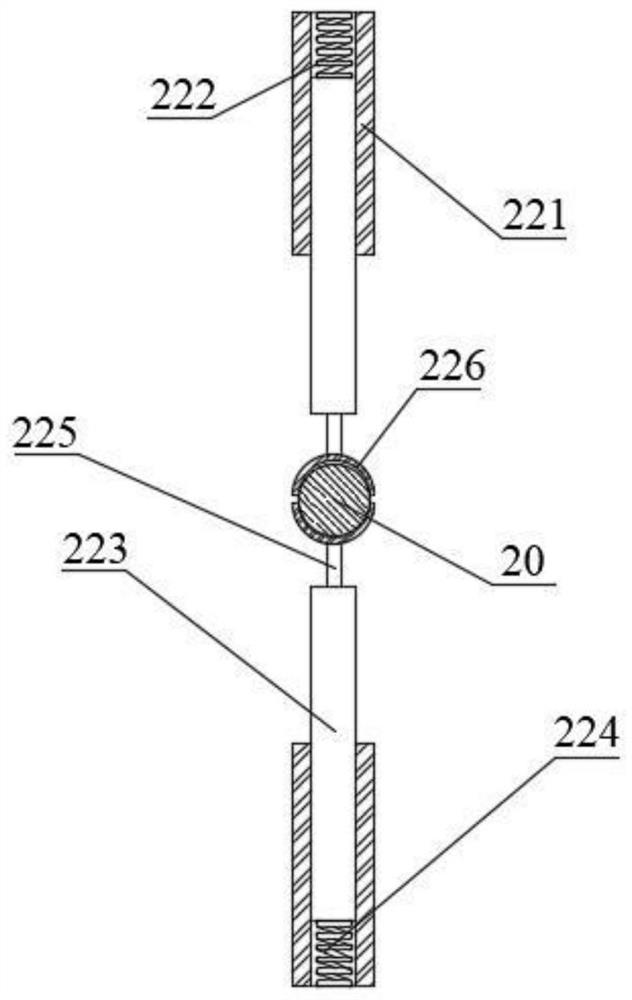

[0039] Such as Figure 2-3 As shown, the transport mechanism 200 includes a transport ...

Embodiment 3

[0042] Such as Figure 4-6 As shown, the present embodiment provides an extrusion mechanism 300, including a screw extrusion chamber 310, an extrusion chamber 320, and a drive mechanism 330. The screw extrusion chamber 310 is located above the extrusion chamber 320, and the drive mechanism 330 is located on the extrusion The bag room 320 is away from the side of the transport cavity 210; the top of the side of the screw extrusion room 310 close to the drive mechanism 330 is provided with a feed hopper 311, and the outer side of one end of the screw extrusion room 310 is connected to a The spiral dragon 313 in the inner cavity of the screw extrusion chamber 310, the bottom of the side of the screw extrusion chamber 310 away from the extrusion chamber 320 is provided with a discharge port 314; The material head 321, the other end corresponding to the feed head 321 is penetrated with an extrusion tube 322 extending into the transport cavity 210, and the radial sides of the extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com