Manufacturing method of 500kV line type lightning arrester

A manufacturing method and lightning arrester technology, which is applied in the manufacture of circuits, resistors, and resistors, can solve the problems of difficult sealing of lightning arresters, flashover of resistor sheet columns, and damage to resistor sheets, so as to ensure good contact, reduce friction, and deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

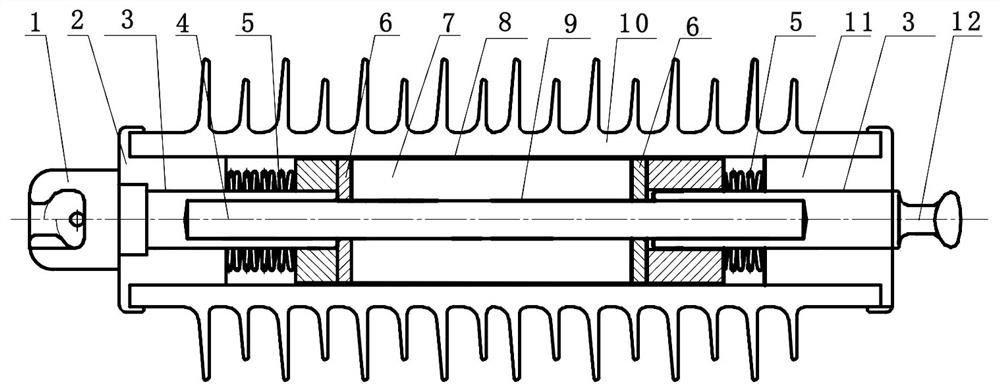

[0022] attached figure 1 It is a structural schematic diagram of a 500KV line type arrester made by the present invention, and its manufacturing method is realized through the following steps:

[0023] 1) Crimping one end of the core rod 4 with the metal tool at the upper end of the arrester;

[0024] 2) Put the axial sealing ring 3 into the multi-channel sealing groove on the fittings of the upper end 1, apply the sealing adhesive on the thread, and tighten and fix it with the upper end cover 2 of the arrester, that is, between the upper and lower ends and the upper and lower end covers The mature O-ring and multi-layer concave groove multiple sealing structure is adopted, and the sealing reliability is high;

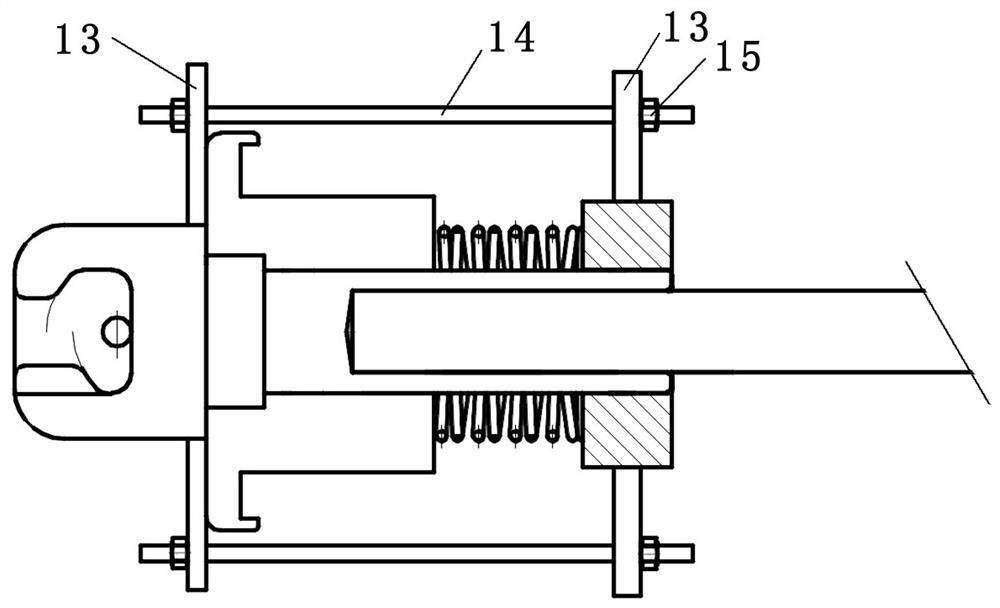

[0025] 3) By using the spring mechanism to compress the tooling, the spring mechanism 5 is compressed and fixed on the high-voltage end of the arrester, that is, the upper end 1, and the first insulating tape 9 is evenly wound on the core rod 4, and the ring-shaped re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com