Sapphire reinforced aluminum alloy motor shell for electric automobile and preparation method of sapphire reinforced aluminum alloy motor shell

A motor housing and electric vehicle technology, applied in electric vehicles, manufacturing motor generators, motors, etc., can solve problems such as high cost and complex mold design, and achieve the goals of improving density, stable processing quality, and reducing defect rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

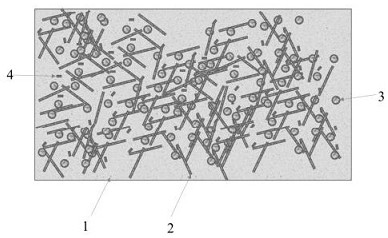

[0037] Such as figure 1 As shown, the sapphire reinforced aluminum alloy motor casing for electric vehicles is composed of sapphire whiskers 4 coated with aluminum alloy film, sapphire fiber 2 coated with aluminum alloy film, nano-sapphire powder 3 coated with aluminum alloy film and aluminum alloy substrate 1 through the reinforcement process. The material is printed and prepared.

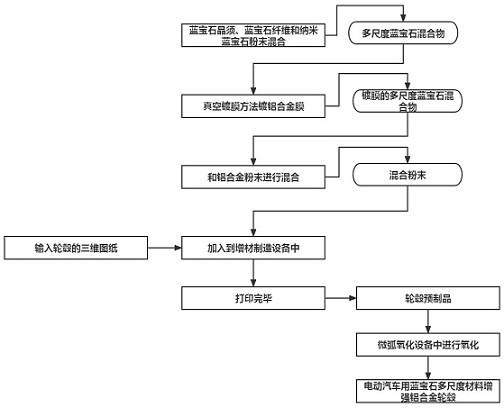

[0038] Such as figure 2 As shown, the sapphire reinforced aluminum alloy motor housing for electric vehicles is prepared by the following steps;

[0039] Step 1, mixing sapphire whiskers, sapphire fibers and nano-sapphire powder to obtain a multi-scale sapphire mixture.

[0040] The sapphire whiskers are 0.5-1 micron in length and 0.1-0.3 micron in diameter; the sapphire fibers are 5-30 micron in length and 1-5 micron in diameter; the nano-sapphire powder has a diameter of 50-500 nanometers.

[0041] Step 2: Use vacuum coating to coat the surface of the multi-scale sapphire mixture to obtain a...

Embodiment 2

[0066] In this embodiment, on the basis of the first embodiment, some process parameters for preparing the sapphire-reinforced aluminum alloy motor housing for electric vehicles are adjusted. Only the parameters for the different parts will be adjusted below, and the others that are the same as those in the first embodiment will not be repeated. stated.

[0067] The sapphire reinforced aluminum alloy motor housing for electric vehicles is prepared by the following method;

[0068] Step 1, mixing sapphire whiskers, sapphire fibers and nano-sapphire powder to obtain a multi-scale sapphire mixture.

[0069] The sapphire whiskers are 0.5-1 micron in length and 0.1-0.3 micron in diameter; the sapphire fibers are 5-30 micron in length and 1-5 micron in diameter; the nano-sapphire powder has a diameter of 50-500 nanometers.

[0070] Step 2: Use vacuum coating to coat the surface of the multi-scale sapphire mixture to obtain a multi-scale aluminum alloy coating composed of sapphire w...

Embodiment 3

[0076] In this embodiment, on the basis of the first embodiment, some process parameters for preparing the sapphire-reinforced aluminum alloy motor housing for electric vehicles are adjusted. Only the parameters for the different parts will be adjusted below, and the others that are the same as those in the first embodiment will not be repeated. stated.

[0077] The sapphire reinforced aluminum alloy motor housing for electric vehicles is prepared by the following method;

[0078] Step 1, mixing sapphire whiskers, sapphire fibers and nano-sapphire powder to obtain a multi-scale sapphire mixture.

[0079] The sapphire whiskers are 0.5-1 micron in length and 0.1-0.3 micron in diameter; the sapphire fibers are 5-30 micron in length and 1-5 micron in diameter; the nano-sapphire powder has a diameter of 50-500 nanometers.

[0080] Step 2: Use vacuum coating to coat the surface of the multi-scale sapphire mixture to obtain a multi-scale aluminum alloy coating composed of sapphire w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whisker length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com