Low leakage current gating switch circuit for multi-path resistance high-precision measurement

A gating switch, high-precision technology, applied in the direction of electronic switches, electrical components, pulse technology, etc., can solve the problems of inaccurate measurement, large leakage current, and inability to eliminate data processing methods, so as to reduce leakage current and leakage current Low, widely enforceable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

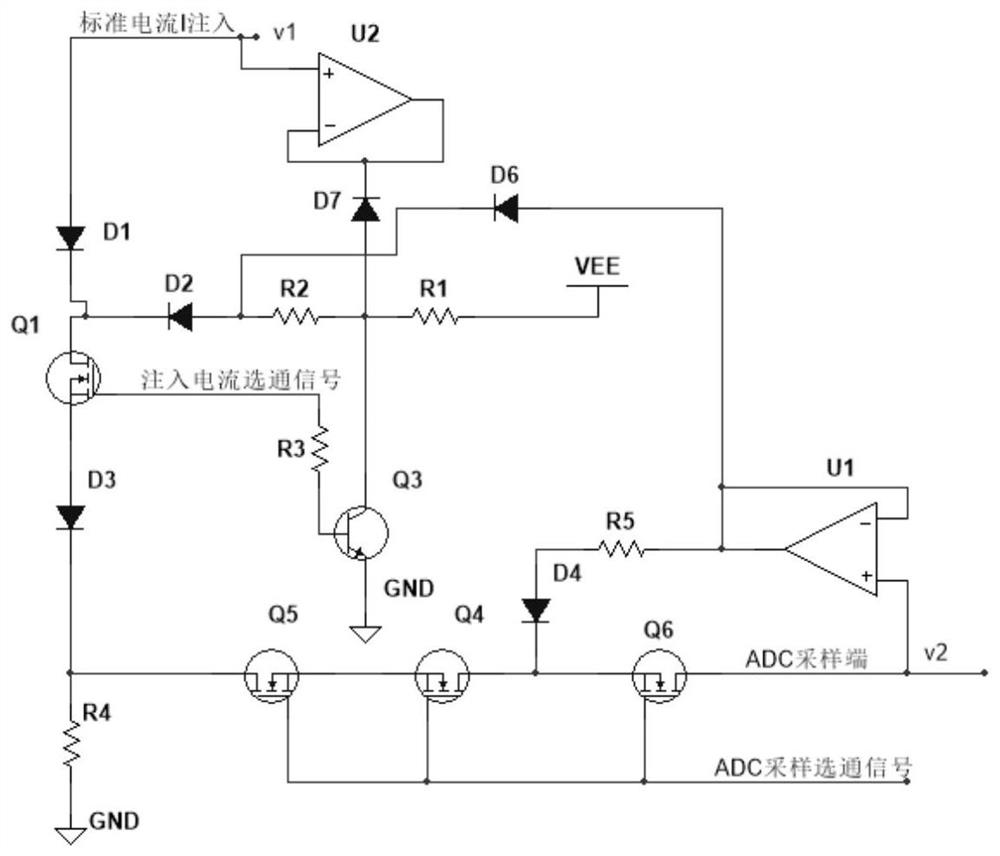

[0023] Such as image 3 As shown, Embodiment 1 of the present invention provides a low-leakage current gating switch circuit for high-precision measurement of multi-channel resistance, including: diodes D1-D7, transistor Q3, MOS transistors Q1, Q6, operational amplifiers U1, U2 .

[0024] Among them, the standard current input terminal is connected to the anode of the diode D1, the cathode of the diode D1 is connected to the drain of the MOS transistor Q1, the source of the MOS transistor Q1 is connected to the anode of the diode D3, and the gate of the MOS transistor Q1 communicates with the injection current selection The cathode of the diode D3 is grounded through the resistance R4 to be measured, the cathode of the diode D3 is also connected to the drain of the MOS transistor Q5, the source of the MOS transistor Q5 is connected to the source of the MOS transistor Q4, and the drain of the MOS transistor Q4 is connected to the The source of the MOS transistor Q6 is connecte...

Embodiment 2

[0037] Such as Figure 4 As shown, the second embodiment of the present invention provides a multi-channel resistance high-precision measurement circuit, including two gating switch circuits as described in the first embodiment. Specifically, in this embodiment, the gate switch circuits share the operational amplifiers U1 and U2.

[0038] In this embodiment, by controlling the level of the injection current gate and the ADC sampling gate in each gate switch circuit, one of the switch circuits can be controlled to perform resistance measurement, and the leakage current is small and the measurement accuracy is high. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com