Refining process of long-carbon-chain dinitrile

A binary nitrile and long carbon chain technology, which is applied in the field of refining process of long carbon chain binary nitrile, can solve problems such as easy coking of ammoniated intermediates, high process control requirements, and affecting the operation of rectification towers, and achieve recovery energy Low consumption, strong controllability and remarkable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A refining process for long carbon chain dibasic nitriles, comprising the following steps:

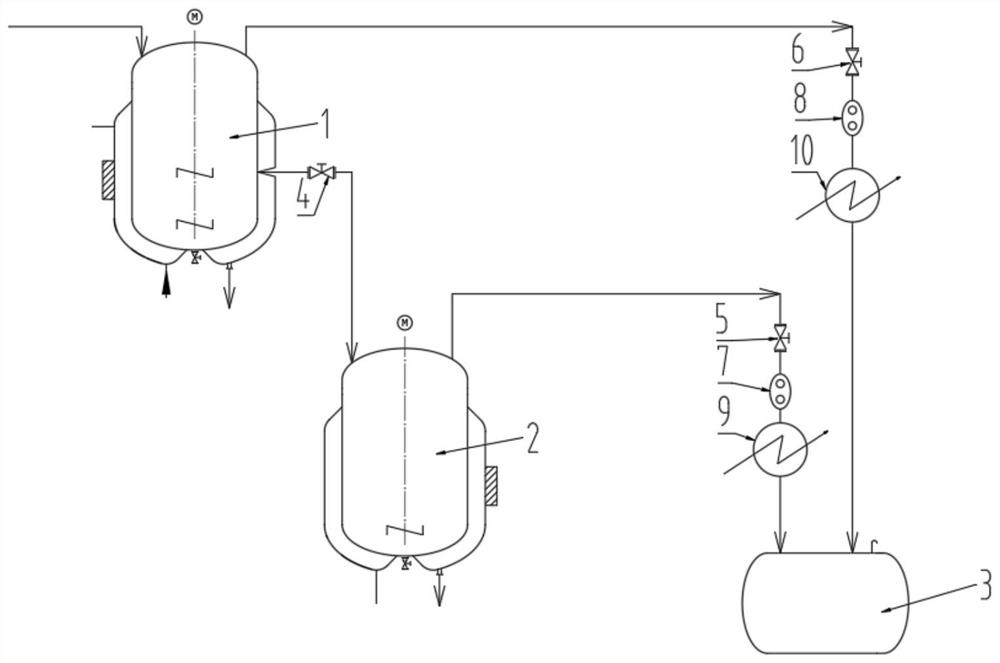

[0048] (1) Vacuum crystallization: put sebaconitrile 1000kg (95.4%) and ethanol 350L (98.5%) into the evaporative crystallizer, start stirring; open the crystallizer precipitation valve 6, start the crystallization precipitation vacuum pump 8 to evacuate to the surface The pressure is -0.1~-0.09MPa, and the evaporation cooling crystallization is carried out, and the volatilized ethanol is condensed and recovered in the solvent collection tank 3 through the crystallization precipitation condenser 10; , stop stirring after 4h and turn off the vacuum pump power supply.

[0049] (2) Separation of crystal and mother liquor: after the vacuum crystallization is completed, stop stirring, settle for 20min, open the solid-liquid interface valve 4, put the supernatant liquid in the crystallizer into the mother liquor tank, and the binary nitrile crystal stays in the evaporative crystallize...

Embodiment 2

[0054] Embodiment 2 (repetitive test)

[0055] Raw material purity and proportioning are the same, adopt the identical technological condition with embodiment 1, investigate test result, see table 1.

Embodiment 3

[0056] Embodiment 3 (repetition test)

[0057] Raw material purity and proportioning are the same, adopt the identical technological condition with embodiment 1, investigate test result, see table 1.

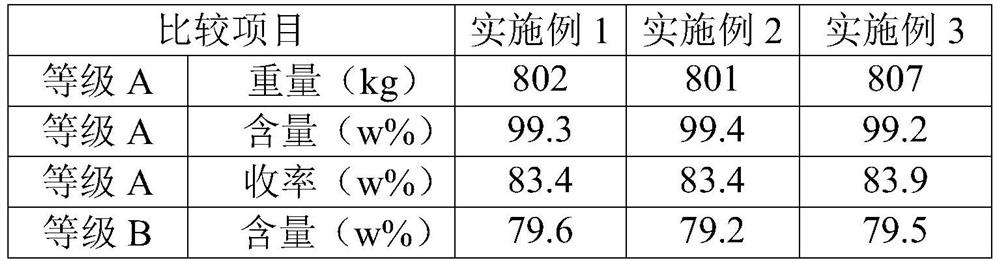

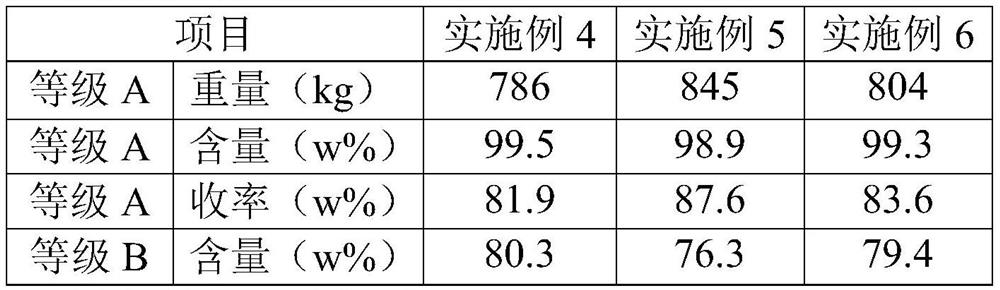

[0058] Table 1 Sebaconitrile refined repeatability test result table (grade A and grade B)

[0059]

[0060] Note: The content analysis adopts gas chromatography

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com