Application of nanoparticle tracking analyzer in surfactant aggregate characterization

A surfactant and nanoparticle technology, used in particle and sedimentation analysis, particle size analysis, analysis of materials, etc., can solve problems such as cumbersome and scattered operations, and achieve the effect of simplifying the analysis process, improving reliability, and improving analysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

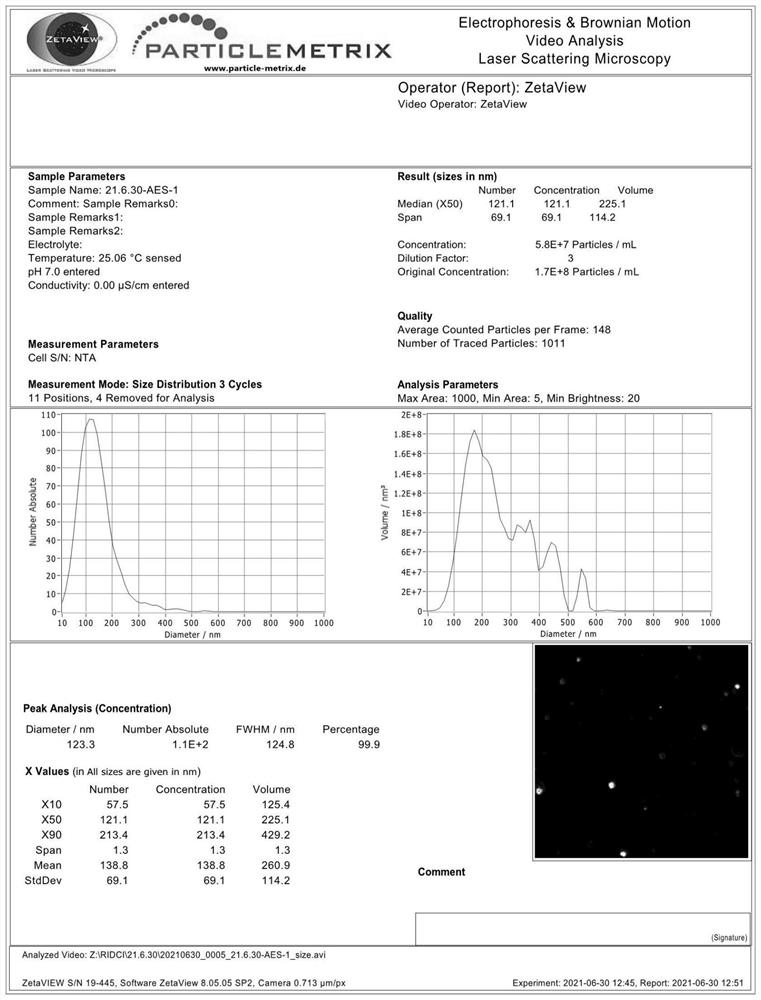

Embodiment 1

[0036] The steps to characterize surfactant aggregates using the Nanoparticle Tracking Analyzer are as follows:

[0037] (1) Turn on the power and start the program, inject distilled water into the sample pool through the syringe for rinsing, inject the particle size standard solution into the sample pool successively for rinsing and calibration of the laser light source and microscope, rinse the sample pool with water, and rinse until the particle counting reading When it is less than 10 and the Cell Quality Result of the sample cell shows Good Good or Very Good; inject the particle size standard solution into the sample cell through a syringe, and calibrate the laser light source and microscope;

[0038] (2) Fatty alcohol polyoxyethylene ether sodium sulfate (AES) aqueous solution of preparation 15mmol / L;

[0039] (3) After setting the temperature parameter of the temperature control unit to 25° C., inject the AES aqueous solution in step (2) into the sample cell through a s...

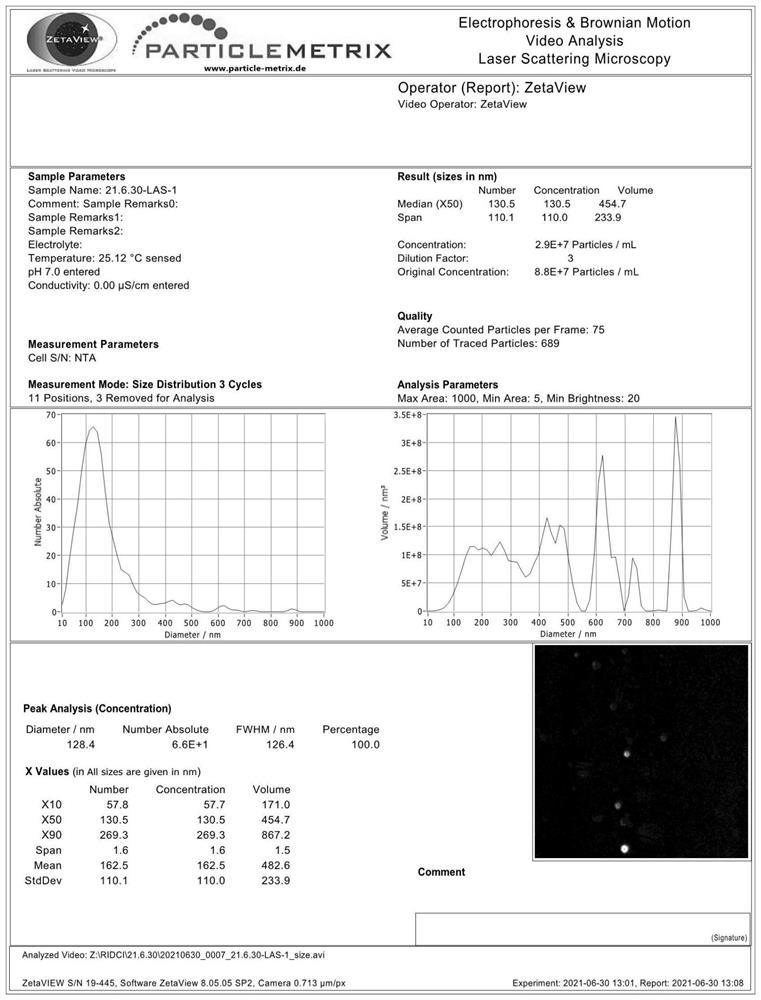

Embodiment 2

[0043] The steps to characterize surfactant aggregates using the Nanoparticle Tracking Analyzer are as follows:

[0044] (1) Turn on the power and start the program, inject distilled water into the sample pool through the syringe for rinsing, inject the particle size standard solution into the sample pool successively for rinsing and calibration of the laser light source and microscope, rinse the sample pool with water, and rinse until the particle counting reading When it is less than 10 and the Cell Quality Result of the sample cell shows Good Good or Very Good; inject the particle size standard solution into the sample cell through a syringe, and calibrate the laser light source and microscope;

[0045] (2) prepare the linear alkylbenzene sulfonate sodium (LAS) aqueous solution of 6mmol / L;

[0046] (3) After setting the temperature parameter of the temperature control unit to 25°C, inject the LAS aqueous solution in step (2) into the sample cell through a syringe for measur...

Embodiment 3

[0050] The steps to characterize surfactant aggregates using the Nanoparticle Tracking Analyzer are as follows:

[0051] (1) Turn on the power and start the program, inject distilled water into the sample pool through the syringe for rinsing, inject the particle size standard solution into the sample pool successively for rinsing and calibration of the laser light source and microscope, rinse the sample pool with water, and rinse until the particle counting reading When it is less than 10 and the Cell Quality Result of the sample pool is displayed as Good Good or Very Good (Very Good); inject the particle size standard solution into the sample pool through a syringe, and calibrate the laser light source and microscope;

[0052] (2) prepare the linear alkylbenzene sulfonate sodium (LAS) aqueous solution of 6mmol / L;

[0053] (3) After setting the temperature parameter of the temperature control unit to 25°C, inject the LAS aqueous solution in step (2) into the sample cell throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com