MEMS packaging method

A method of encapsulation and a technology for encapsulating shells, which are applied in the fields of decorative arts, microstructure devices, and manufacturing microstructure devices, etc., which can solve problems such as rising product costs, small expenses for depreciated finished products, and impact on product competitiveness, and achieve low plastic packaging costs , Saving packaging costs, the effect of unaffected competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

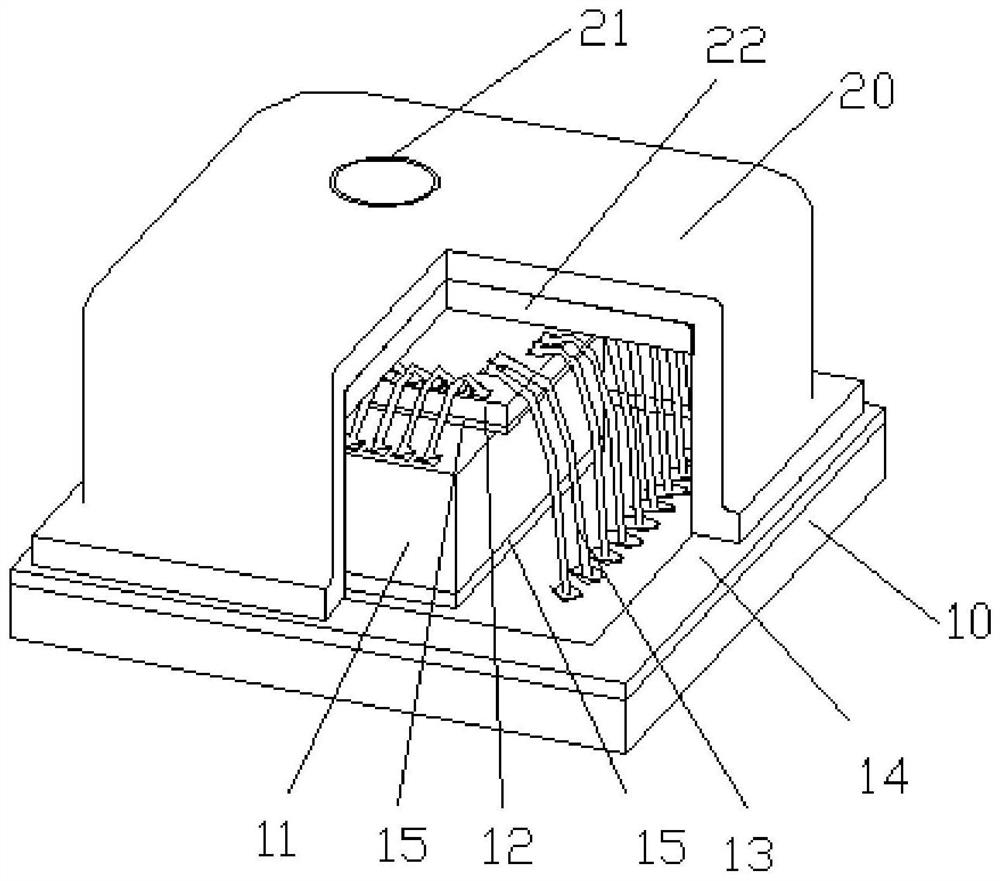

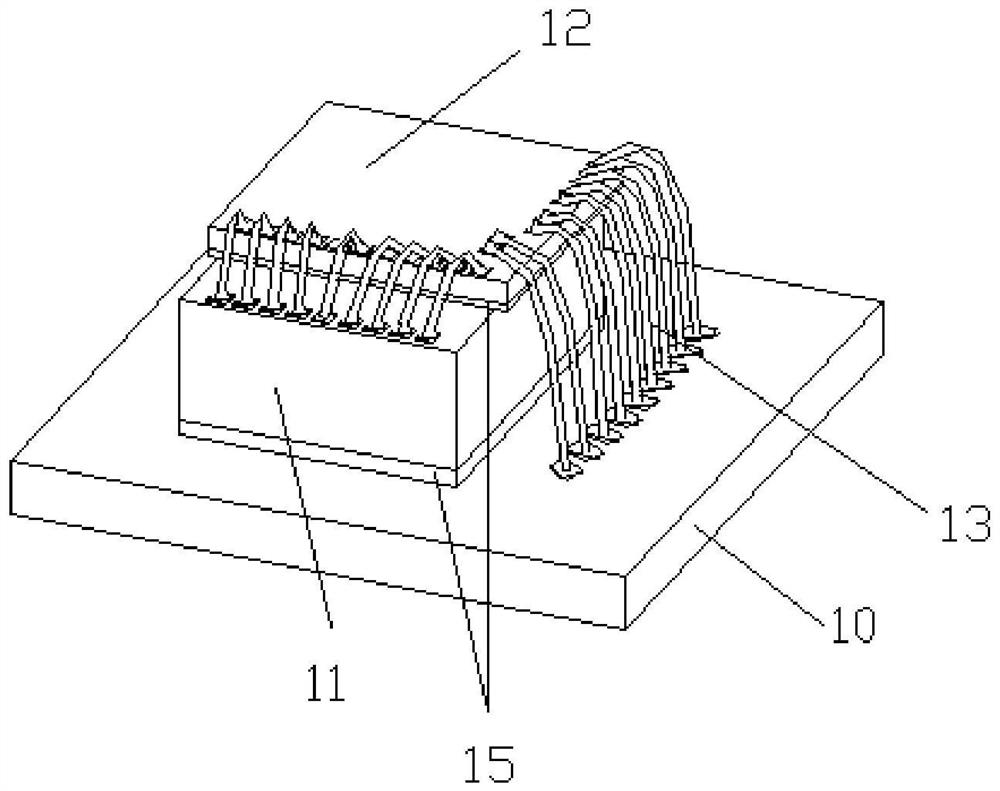

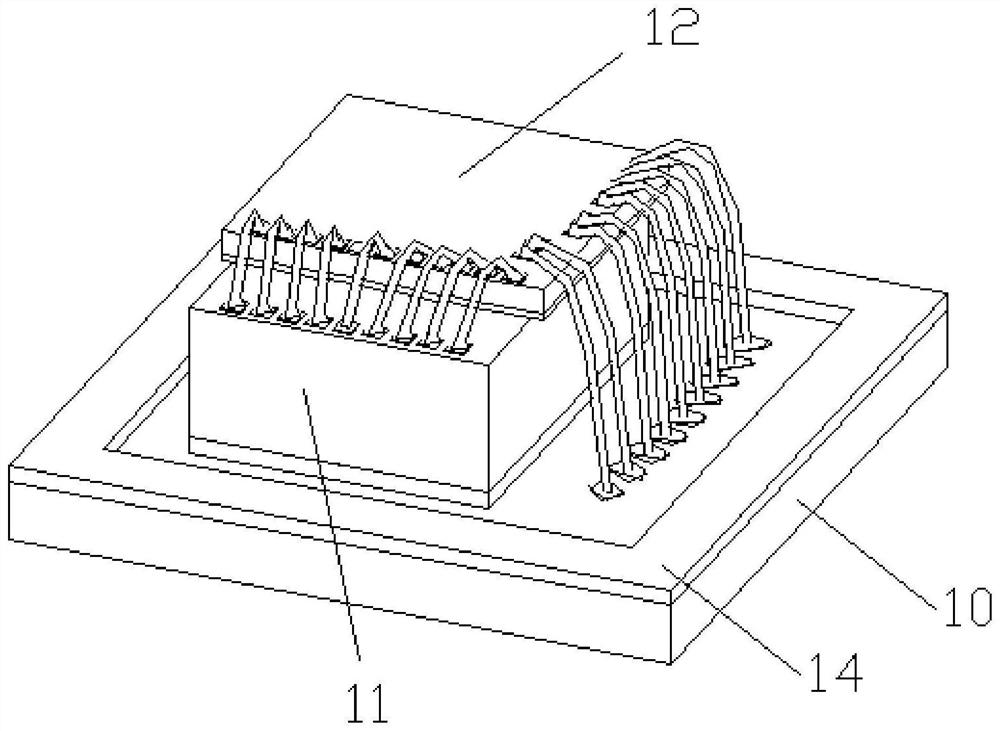

[0047] Example: Figure 1-5 As shown, a MEMS packaging method includes the following steps:

[0048] Step 1: Assembly: figure 2 As shown, the chip group is attached to the substrate 10, and the gold wire 13 is connected to the chipset and the substrate 10 after baked.

[0049] Step 2: Painting the solder paste and cap: Apply the solder paste 14 points on the copper foil around the substrate, such as image 3 Disted, will Figure 4 The encapsulation housing 20 is provided on the solder paste 14 of the substrate, and the solder paste is soldered by reflow, and the package housing 20 is welded to the substrate 10, and the semi-finished product is obtained, wherein the top surface of the package housing is provided. Small hole 21;

[0050] Step 3: Invert the clipping hole: The upper surface of the top surface of the package housing is bonded to the flip mold of the epoxy resin. After heating, the epoxy resin is placed into the cavity of the package housing through the small hole 21 and blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com