Preparation method of multi-enzyme-containing efficient all-purpose membrane cleaning agent

A film cleaning agent, high-efficiency technology, applied in the direction of biochemical equipment and methods, detergent composition, detergent compounding agent, etc., can solve the problems of difficult storage of cleaning agents, affect the use, destroy the stability of enzyme preparations, etc., and achieve expansion Optimum temperature range, stable space, fast and convenient cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

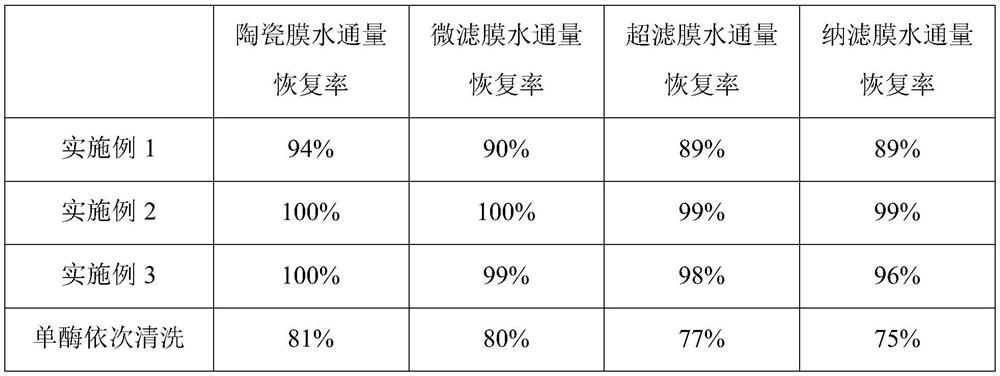

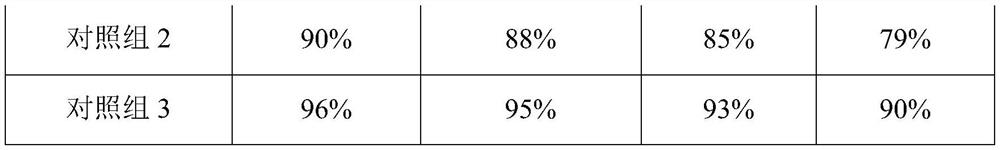

Embodiment 1

[0035] This embodiment provides a method for preparing a multi-enzyme-containing high-efficiency all-round membrane cleaning agent, comprising the following steps:

[0036](1) Preparation of glycosylase: Mix liquid acid protease, acid cellulase, α-amylase, pectinase, and lipase with glucosamine at a mass ratio of 2:1, and add 5 U / g of protein Transglutaminase. The reaction was stirred in a 25°C water bath for 6 hours to prepare the enzyme-glucose graft.

[0037] (2) Preparation of small molecule stabilizers by negative electrospray ionization and high-energy collision induction: VG-ZAB-2SE double-focusing mass spectrometer was used in the experiment. Hydrated deoxyribose samples were introduced into the spray needle via the Elite Pump 11 syringe motor at a flow rate of 3 μl / min. Needle voltages in the range of 5.15-5.66 kV allow for continuous jetting into an inlet capillary with an inner diameter of 750 μm. The inlet capillary was heated to 155-158°C to prevent clogging of...

Embodiment 2

[0041] This embodiment provides a method for preparing a multi-enzyme-containing high-efficiency all-round membrane cleaning agent, comprising the following steps:

[0042] (1) Preparation of glycosylase: Mix liquid acid protease, acid cellulase, α-amylase, pectinase, and lipase with glucosamine at a mass ratio of 3:1, and add 10 U / g of protein Transglutaminase. The reaction was stirred in a 35°C water bath for 3 hours to prepare the enzyme-glucose graft.

[0043] (2) Preparation of small molecule stabilizers by negative electrospray ionization and high-energy collision induction: VG-ZAB-2SE double-focusing mass spectrometer was used in the experiment. Hydrated deoxyribose samples were introduced into the spray needle via the Elite Pump 11 syringe motor at a flow rate of 4 μl / min. Needle voltages in the range of 5.15-5.66 kV allow for continuous jetting into an inlet capillary with an inner diameter of 750 μm. The inlet capillary was heated to 155-158°C to prevent clogging ...

Embodiment 3

[0047] This embodiment provides a method for preparing a multi-enzyme-containing high-efficiency all-round membrane cleaning agent, comprising the following steps:

[0048] (1) Preparation of glycosylase: Mix liquid acid protease, acid cellulase, α-amylase, pectinase, and lipase with glucosamine at a mass ratio of 4:1, and add 10 U / g of protein Transglutaminase. The reaction was stirred in a 45°C water bath for 1 hour to prepare the enzyme-glucose graft.

[0049] (2) Preparation of small molecule stabilizers by negative electrospray ionization and high-energy collision induction: VG-ZAB-2SE double-focusing mass spectrometer was used in the experiment. Hydrated deoxyribose samples were introduced into the spray needle via the Elite Pump 11 syringe motor at a flow rate of 5 μl / min. Needle voltages in the range of 5.15-5.66 kV allow for continuous jetting into an inlet capillary with an inner diameter of 750 μm. The inlet capillary was heated to 155-158°C to prevent clogging o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com