A kind of high-strength refractory nickel-based superalloy and preparation method thereof

A nickel-based superalloy, hard-to-deform technology, applied in the field of preparation of nickel-based superalloys, can solve the problems of high Co content, high alloy manufacturing costs, etc., to achieve the effect of improving bonding force, excellent durability, and improving temperature bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The above-mentioned high-strength refractory nickel-based superalloy adopts the following preparation method, comprising the following steps:

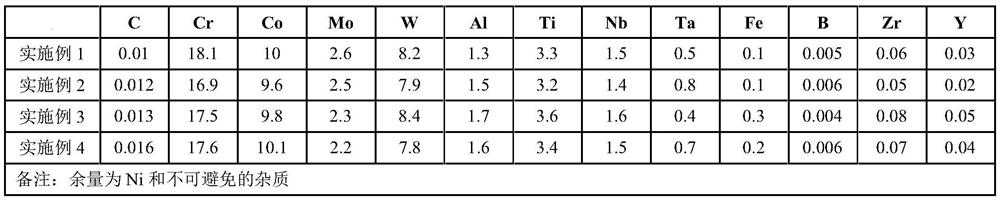

[0048] S1, vacuum induction smelting, batching is carried out according to the above element ratio, Ni, Cr, Co, W, Mo, C are added to the induction furnace, and the material is smelted under the conditions of vacuum degree ≤2.7Pa and power of 300-600KW, and full melting After refining, the power is 600-800KW and the refining temperature is 1520-1580℃ for 30-60min; then reduce the power to 200-600KW, lower the molten steel temperature to 1470-1520℃, add Ti, Al, Nb, Ta , Zr and B are alloyed and smelted to obtain molten steel. The measured elements in molten steel meet the requirements of C: 0.005-0.02%, Cr: 15.0-19.0%, Co: 8.0-11.0%, Al: 1.0-2.0%, Ti: 3.0- 4.0%, Nb: 1.0 to 2.0%, Ta: 0.3 to 1.0%, Mo: 1.0 to 3.0%, W: 7.0 to 9.0%, B: 0.004 to 0.01%, Zr: 0.05 to 0.11%, and then charged with 10000Pa Ar After adding Y, continue smelti...

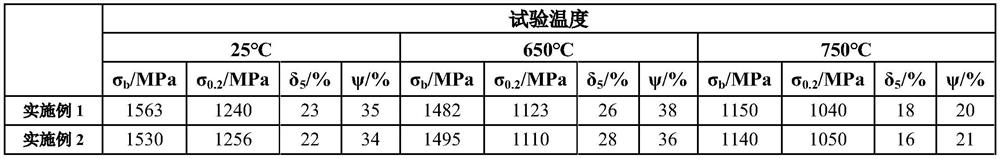

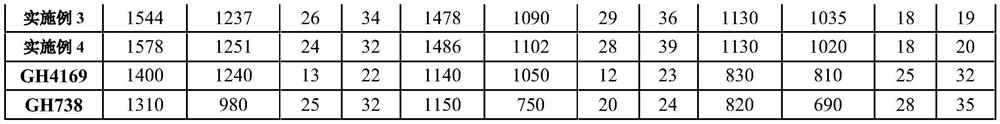

Embodiment 1

[0059]S1, vacuum induction smelting, using selected high-purity raw materials as alloy raw materials and ingredients according to the above element ratio, to ensure that the surface of the alloy raw material block is derusted, clean and free of oil pollution, etc., special attention should be paid to Si, Mn, Cu Substitute C according to the upper limit; add Ni, Cr, Co, W, Mo, and C to the induction furnace, and carry out chemical mixing under the conditions of vacuum degree ≤2.7Pa and power of 300-600KW. After full melting, the power is 600 ~800KW and refining temperature of 1520℃ for 30min; then reduce the power to 200~600KW, reduce the temperature of molten steel to 1480℃, add Ti, Al, Nb, Ta, Zr, B for alloying and smelting to obtain molten steel, Measured in molten steel to satisfy C: 0.010%, Cr: 18.1%, Co: 10.0%, Mo: 2.60%, W: 8.2%, Al: 1.3%, Ti: 3.3%, Nb: 1.5%, Ta: 0.5%, B: 0.005%, Zr: 0.06%, the content of each element in the molten steel is within the index range of hig...

Embodiment 2

[0069] S1, vacuum induction smelting, using selected high-purity raw materials as alloy raw materials and ingredients according to the above element ratio, to ensure that the surface of the alloy raw material block is derusted, clean and free of oil pollution, etc., special attention should be paid to Si, Mn, Cu Substitute C according to the upper limit; add Ni, Cr, Co, W, Mo, and C to the induction furnace, and carry out chemical mixing under the conditions of vacuum degree ≤2.7Pa and power of 300-600KW. After full melting, the power is 600 ~800KW and refining temperature of 1540℃ for 45min; then reduce the power to 200~600KW, lower the molten steel temperature to 1500℃, add Ti, Al, Nb, Ta, Zr, B for alloying and smelting to obtain molten steel, The measured element content in molten steel satisfies C: 0.012%, Cr: 16.9%, Co: 9.6%, Mo: 2.50%, W: 7.9%, Al: 1.5%, Ti: 3.2%, Nb: 1.4%, Ta: 0.8 %, B: 0.006%, Zr: 0.05%, the content of each element in the molten steel is within the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com