Super-hydrophilic conductive nanofiber membrane and method for treating emulsion by using super-hydrophilic conductive nanofiber membrane

A conductive nano, super-hydrophilic technology, applied in chemical instruments and methods, electricity to separate liquids, membranes, etc., can solve the problems of low processing flux, easy to fall off the conductive layer, limited hydrophilicity, etc., and achieve processing efficiency High, simple operation, strong anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

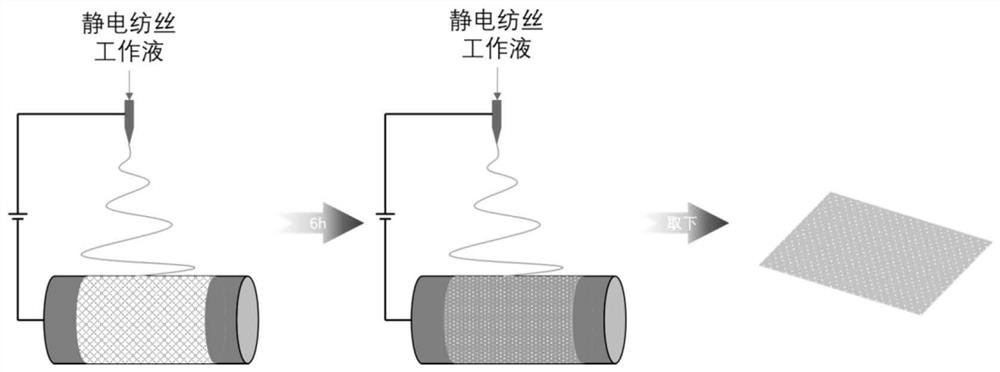

[0055] Such as figure 2 Shown, the preparation method of the superhydrophilic conductive nanofiber membrane of the present embodiment is:

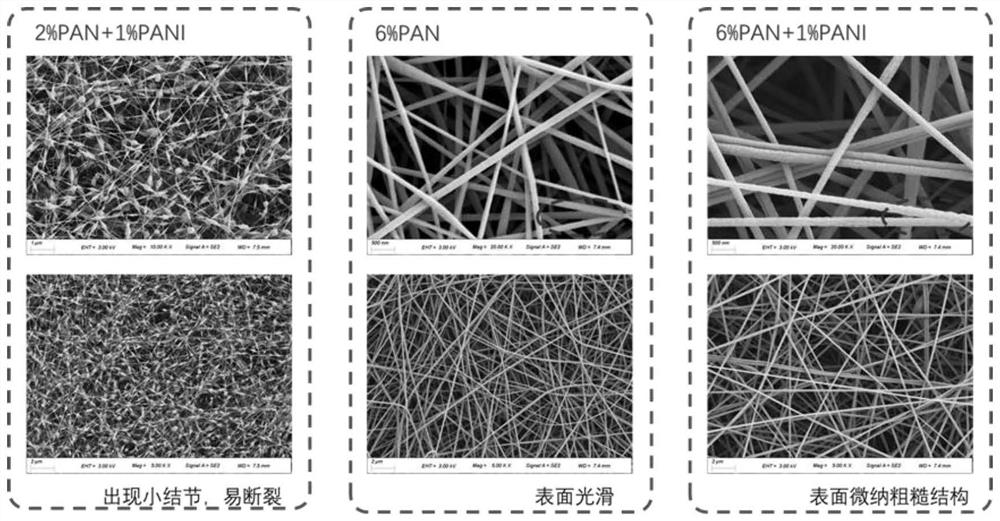

[0056] P1. Weigh 150mg of polyaniline powder and 190mg of 10-camphorsulfonic acid crystals, dissolve them in 15mL of N,N-dimethylformamide, stir at 300rpm with a magnetic stirrer for 12h at room temperature, and configure the first concentration to be 1 % polyaniline and a second concentration of 1.27% 10-camphorsulfonic acid in N,N-dimethylformamide suspension.

[0057] P2. Use a Nylon needle filter with a specification of 0.22 μm to filter the above suspension, collect the filtered solution as a pre-prepared solution for the electrospinning working solution, and keep the temperature (room temperature) constant during the operation.

[0058] P3. Weigh 900 mg of polyacrylonitrile powder and dissolve it in the above prefabricated solution, stir it with a magnetic stirrer at 600 rpm for 12 hours at a constant room temperature, and prepare ...

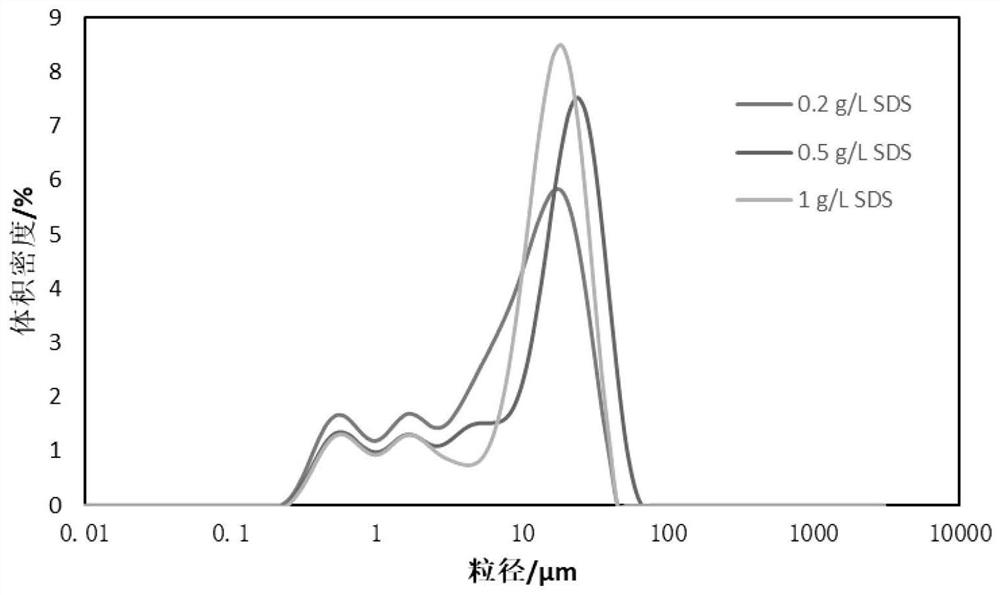

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com