Core-shell structure material as well as preparation method and application thereof

A core-shell structure and shell technology, applied in the field of materials, can solve problems such as unstable structure, weak adsorption capacity, and single adsorption site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

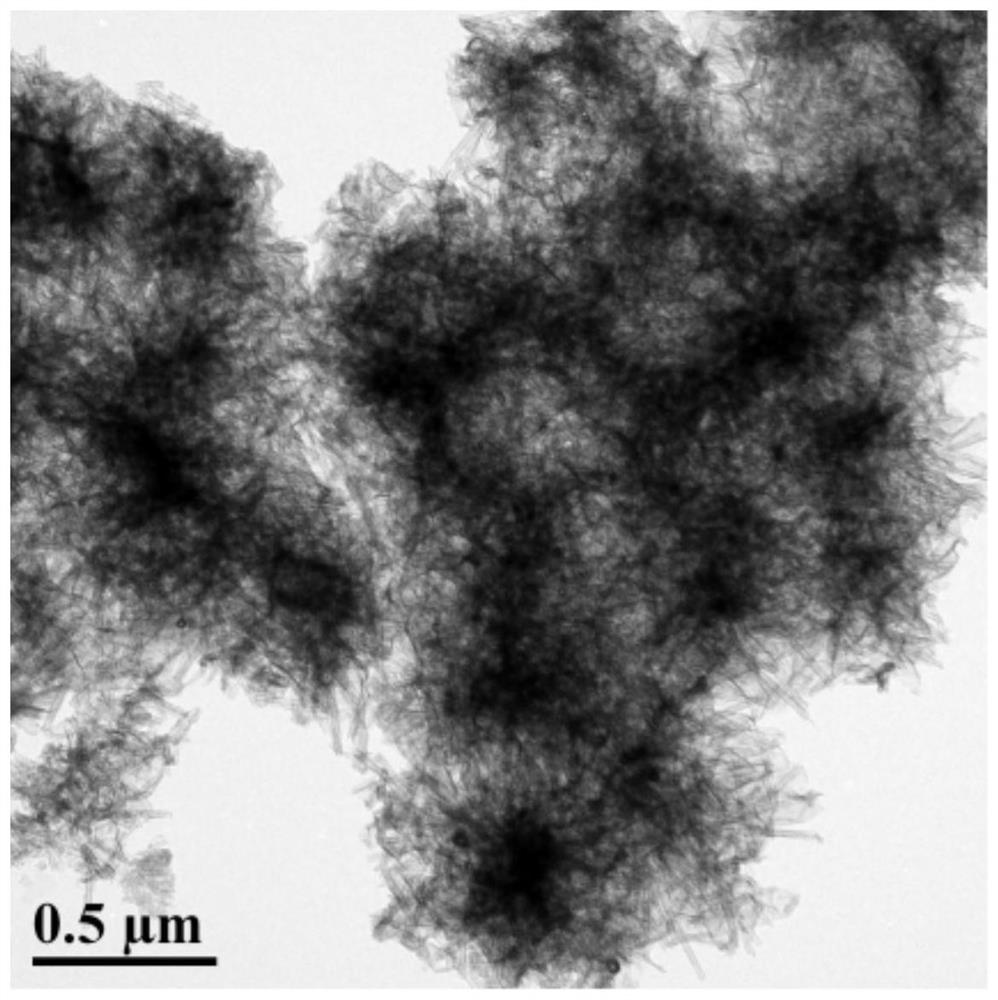

Image

Examples

Embodiment 1

[0061] This embodiment discloses a core-shell structure material. The core-shell structure material is a hybrid ZIF-8@MIL-100(Fe) core-shell structure material. In the core-shell structure material, ZIF-8 and MIL- 100 (Fe) The ratio of the amount of substance is 1:1.

[0062] In this example, the above-mentioned core-shell structure material was prepared, and the specific process was as follows:

[0063] (1) Dissolve 4g of sodium hydroxide powder in 8mL of deionized water, completely dissolve to form a concentrated solution, and wait for it to cool down to room temperature to obtain a concentrated solution of sodium hydroxide;

[0064] (2) Slowly add 7g of trimesic acid powder into the obtained concentrated sodium hydroxide solution, stir with an iron spoon until the reaction is complete and cool to room temperature;

[0065] (3) Filtrate and recover the filtrate with a needle filter (water phase 0.22 μm);

[0066] (4) Add excessive absolute ethanol and produce white precipi...

Embodiment 2

[0084] This example prepares a core-shell structure material, the difference from Example 1 is that steps 14-16 are different, specifically:

[0085] (14) Dissolve sodium trimesate in dispersion I by weighing 0.82 g (the amount of substance is 3 mmol) to make dispersion II, and keep the ZIF-8 powder fully dispersed during the period;

[0086] (15) Weigh ferrous sulfate heptahydrate and dissolve it in 50mL deionized water at a concentration of 0.89g / 50mL (the concentration of the corresponding substance is 3.2mmol / 50mL), and make an aqueous solution of ferrous sulfate;

[0087] (16) Add dispersion liquid II and ferrous sulfate aqueous solution to a 250mL Erlenmeyer flask with a cover, mix well, then transfer to a constant temperature shaker at a speed of 200rpm at 4°C and shake overnight (more than 8 hours). After the reaction is over, get Mixture II;

[0088] The coating ratio of the core-shell structure sample obtained in this example is 1:2.

Embodiment 3

[0090] This example prepares a core-shell structure material, the difference from Example 1 is that steps 14-16 are different, specifically:

[0091] (14) Weigh and dissolve sodium trimesate in dispersion I, add 1.64 g (the amount of substance is 6 mmol), make dispersion II, and keep the ZIF-8 powder fully dispersed during the period;

[0092] (15) Weigh ferrous sulfate heptahydrate and dissolve it in 50mL deionized water at a concentration of 1.78g / 50mL (the concentration of the corresponding substance is 6.4mmol / 50mL), and make an aqueous solution of ferrous sulfate;

[0093] (16) Add dispersion liquid II and ferrous sulfate aqueous solution to a 250mL Erlenmeyer flask with a cover, mix well, then transfer to a constant temperature shaker at a speed of 200rpm at 4°C and shake overnight (more than 8 hours). After the reaction is over, get Mixture II;

[0094] The coating ratio of the core-shell structure sample obtained in this example is 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com