Porous silver loaded on copper-based carrier in situ as well as preparation method and application of porous silver

A porous silver and copper-based technology, applied in the field of metal materials, can solve the problems of easy aggregation of silver nano-basic units, loss of catalyst performance, long-term synthesis process, etc., and achieve excellent SERS performance, uniform distribution, and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of porous silver supported in situ on a copper-based carrier, the preparation method is as follows:

[0051] 1) Soak the copper foil with a 50% fluoroboric acid aqueous solution at room temperature for 10 minutes to remove oxides on its surface, then wash with water and dry to obtain a pretreated copper-based carrier.

[0052] 2) Prepare 100mL of silver nitrate (20mmol / L) and 2-chlorobenzoic acid (10mmol / L) mixed solution.

[0053] 3) At 20° C., immerse 20 mg of the pretreated copper foil in 2 mL of the mixed solution for 5 minutes to react.

[0054] 4) Rinse the obtained porous silver-loaded copper foil with ethanol and deionized water in sequence, and dry to obtain the in-situ-loaded porous silver on the copper-based carrier.

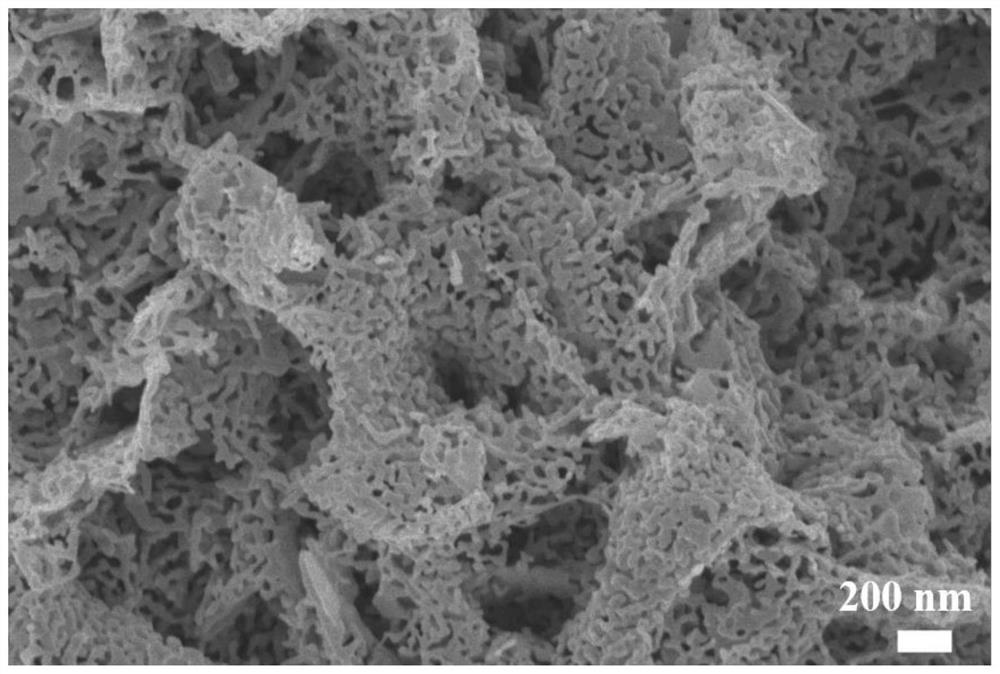

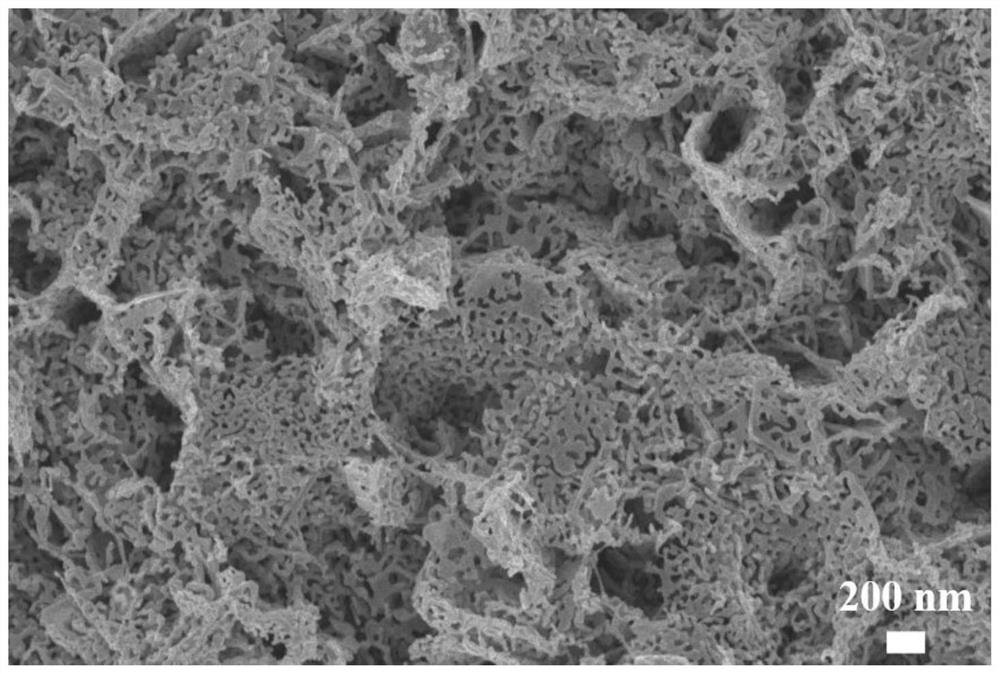

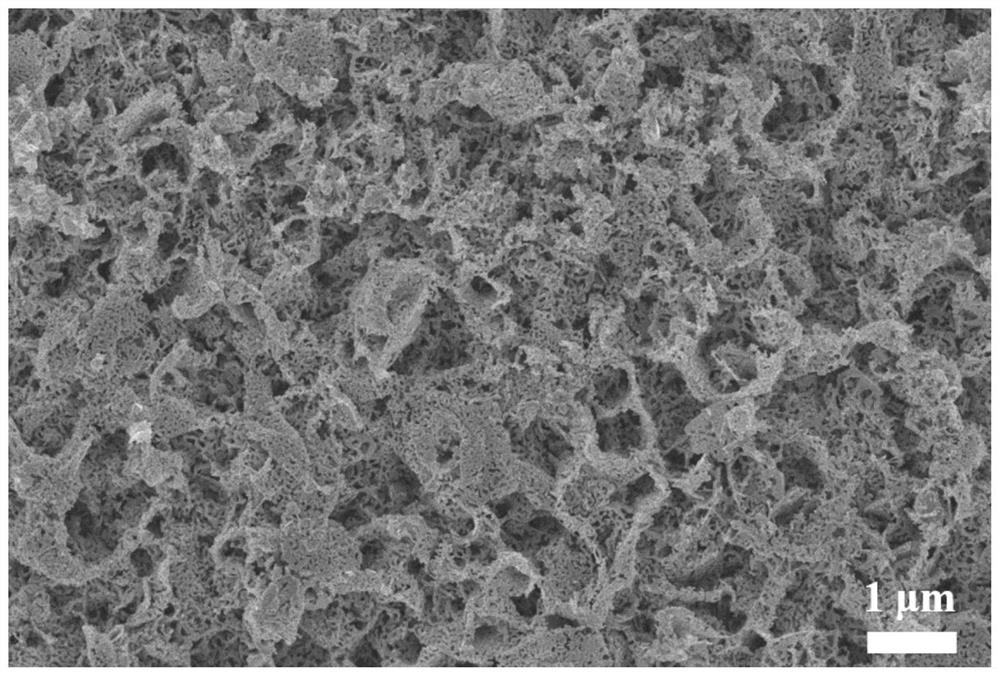

[0055] The SEM image of the porous silver supported in situ on the copper-based carrier prepared in this example is as follows Figure 1-4 As shown, the porous structure exists in the form of three-dimensional openings, a...

Embodiment 2

[0057] A method for preparing porous silver supported in situ on a copper-based carrier is as described in Example 1, except that copper foil is used instead of copper foil.

[0058] The SEM morphology of the porous silver supported in situ on the copper-based carrier obtained in this example is as follows Figure 5 It can be seen from the figure that when the copper-based material is replaced by copper foam, a curled porous silver nanosheet structure with uniform distribution and high porosity can still be grown on its surface.

Embodiment 3

[0060] A method for preparing porous silver supported in situ on a copper-based carrier, as described in Example 1, except that a copper mesh is used instead of copper foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com