Method for enhancing density of ribs of gravity casting positive grid

A gravity casting, positive plate technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of poor acid corrosion resistance, insufficient dense structure of grid conductive ribs, etc. The effect of floating charge service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

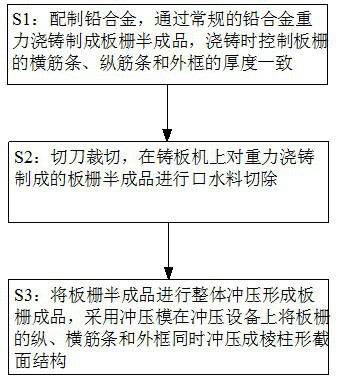

[0025] A method for increasing the density of gravity cast positive pole grid ribs, comprising the steps of:

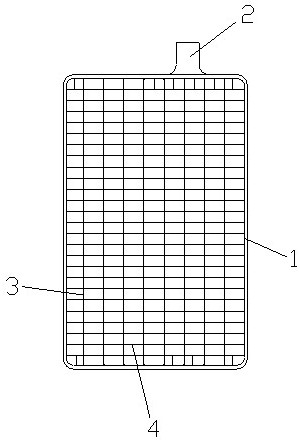

[0026] S1: prepare lead alloy, and make the grid semi-finished product through conventional lead alloy gravity casting, and control the thickness of the transverse rib 4, longitudinal rib 3 and outer frame 1 of the grid during casting;

[0027] S2: Cutting with a cutter, cutting off the drool material on the semi-finished grid made by gravity casting on the casting machine;

[0028] S3: The grid uses a stamping die to simultaneously stamp the longitudinal and transverse ribs and the outer frame of the grid into a prismatic cross-sectional structure on the stamping equipment; finally, the overall stamping forms the finished grid.

[0029] With this embodiment, after the gravity casting is formed, the grid is stamped as a whole, which improves the density of the grid alloy, improves the corrosion resistance, and prolongs the battery life. Ensure that the thickness of e...

Embodiment 2

[0031] A method for increasing the density of gravity cast positive pole grid ribs, comprising the steps of:

[0032] S1: prepare lead alloy, and make the grid semi-finished product through conventional lead alloy gravity casting, and control the thickness of the transverse rib 4, longitudinal rib 3 and outer frame 1 of the grid during casting;

[0033] S2: Cutting with a cutter, cutting off the drool material on the semi-finished grid made by gravity casting on the casting machine;

[0034] S3: The grid uses a stamping die to simultaneously stamp the longitudinal and transverse ribs and the outer frame of the grid into a prismatic cross-sectional structure on the stamping equipment; finally, the overall stamping forms the finished grid.

[0035] Wherein, the specific steps of forming the finished grid by integral stamping are: making a set of stamping dies on the stamping equipment at the tail end of the casting machine; engraving grooves with the same shape as the positive g...

Embodiment 3

[0039] A method for increasing the density of gravity cast positive pole grid ribs, comprising the steps of:

[0040] S1: Prepare lead alloy, and make the grid semi-finished product through conventional lead alloy gravity casting, and control the thickness of the transverse rib, longitudinal rib and outer frame of the grid during casting;

[0041] S2: Cutting with a cutter, cutting off the drool material on the semi-finished grid made by gravity casting on the casting machine;

[0042] S3: The grid uses a stamping die to simultaneously stamp the longitudinal and transverse ribs and the outer frame of the grid into a prismatic cross-sectional structure on the stamping equipment; finally, the overall stamping forms the finished grid;

[0043] In the S3 step of the present invention, the longitudinal and transverse ribs and the outer frame of the grid are simultaneously stamped into a prismatic cross-sectional structure on the stamping equipment by using a stamping die; The thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com