Ultrahigh-strength, low-warping and low-floating-fiber PA reinforced material and preparation process thereof

An ultra-high-strength, reinforcing material technology, applied to low-floating fiber PA reinforcing material and its preparation process, low-warpage, ultra-high-strength fields, can solve the problems of increasing production costs, general improvement effect, and easy existence of floating fibers. , to achieve the effect of preventing glass fiber exposure, good gloss and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

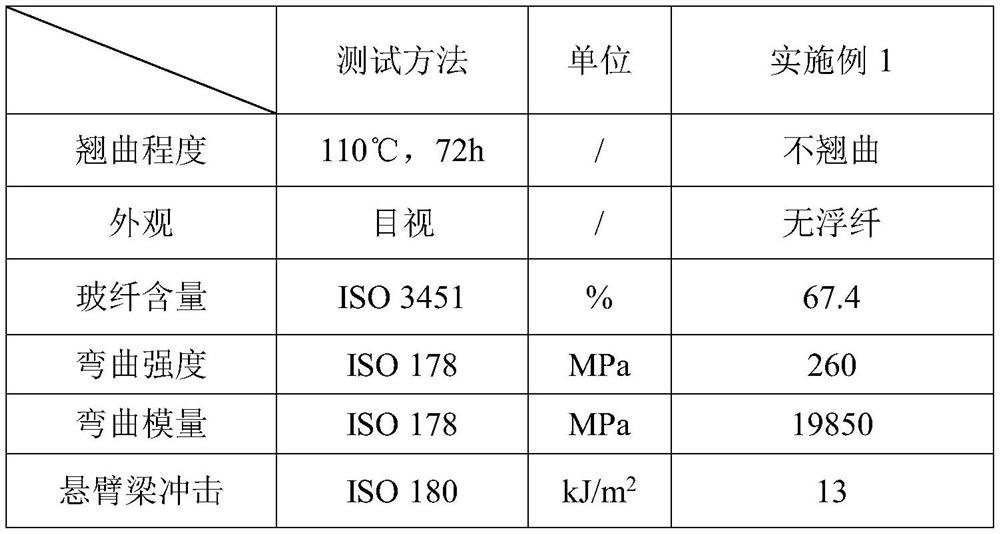

Embodiment 1

[0054] Ultra-high strength, low warpage, low floating fiber PA reinforcement material, the preparation raw materials are as follows:

[0055] PA6 22 Kg (high melting refers to PA6 12Kg, the melt index is 80g / 10min; low melting refers to PA6 10Kg, the melting index is 40g / 10min)

[0056] Glass fiber 65Kg

[0057] 1250 mesh talcum powder 3Kg

[0058] Functional compatibilizer 5Kg

[0059] Lubricant EBS 0.4Kg

[0060] Antioxidant 1.0Kg.

[0061] The preparation steps of ultra-high strength, low warpage and low floating fiber PA reinforced material are as follows:

[0062] S1. Dry PA6 at 110°C for 3 hours;

[0063] S2. Weigh the glass fiber, functional compatibilizer, lubricant, and antioxidant in proportion, stir in a high-speed mixer for 1 minute, and mix well;

[0064] S3. Add the homogeneously mixed material in S2 into the internal mixer, knead and granulate to obtain the glass fiber compatibilizer mixture;

[0065] S4. Weigh the glass fiber compatibilizer mixture, talc...

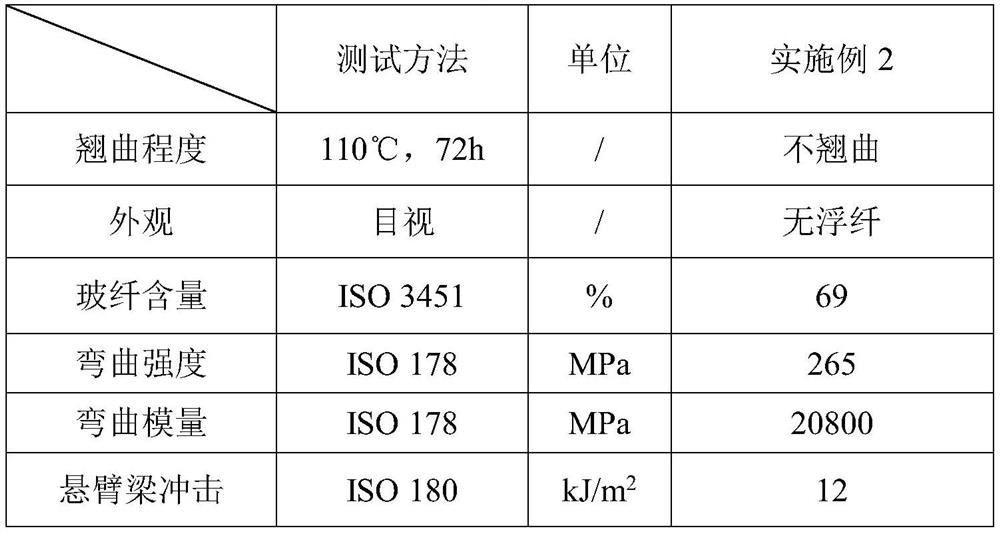

Embodiment 2

[0071] Ultra-high strength, low warpage, low floating fiber PA reinforcement material, the preparation raw materials are as follows:

[0072] PA6 20 Kg (high melting refers to PA6 6Kg, the melt index is 80g / 10min; low melting refers to PA6 14Kg, the melting index is 40g / 10min)

[0073] Glass fiber 70Kg

[0074] 1250 mesh talcum powder 2Kg

[0075] Functional compatibilizer 8Kg

[0076] Lubricant EBS 0.4Kg

[0077] Antioxidant 1.0Kg.

[0078] The preparation steps of ultra-high strength, low warpage and low floating fiber PA reinforced material are as follows:

[0079] S1. Dry PA6 at 110°C for 3 hours;

[0080] S2. Weigh the glass fiber, functional compatibilizer, lubricant, and antioxidant in proportion, stir in a high-speed mixer for 1 minute, and mix well;

[0081] S3. Add the homogeneously mixed material in S2 into the internal mixer, knead and granulate to obtain the glass fiber compatibilizer mixture;

[0082] S4. Weigh the glass fiber compatibilizer mixture, talcu...

Embodiment 3

[0088] Ultra-high strength, low warpage, low floating fiber PA reinforcement material, the preparation raw materials are as follows:

[0089] PA630 Kg (high melting means PA6 13Kg, melt index is 90g / 10min; low melting means PA6 17Kg, melting index is 50g / 10min)

[0090] Glass fiber 75Kg

[0091] 1250 mesh talcum powder 5Kg

[0092] Functional compatibilizer 6Kg

[0093] Lubricant EBS 0.5Kg

[0094] Antioxidant 1.2Kg.

[0095] The preparation steps of ultra-high strength, low warpage and low floating fiber PA reinforced material are as follows:

[0096] S1. Dry PA6 at 100°C for 4 hours;

[0097] S2. Weigh the glass fiber, functional compatibilizer, lubricant, and antioxidant in proportion, stir in a high-speed mixer for 3 minutes, and mix well;

[0098] S3. Add the homogeneously mixed material in S2 into the internal mixer, knead and granulate to obtain the glass fiber compatibilizer mixture;

[0099] S4. Weigh the glass fiber compatibilizer mixture, talcum powder, and P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com