Water-based strippable coating, preparation method and application

A paint, water-based technology, applied in the field of peelable paint preparation, can solve the problems of non-peelable, VOC reduction, side effects, etc., to achieve good high temperature resistance and acid and alkali resistance, large tear strength and tensile strength, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Method for preparing aqueous peeling coating provided by the present invention

[0047] The preparation step of the aqueous peeling coating provided in this embodiment is as follows:

[0048] (1) Take 60 parts of silicide emulsion (purchased from Luking, model PL.3127), 30 slices of pure absulu (purchased from preservation, model BLJ-998AD) and 24 parts of benzole emulsion (purchased from Good, model BLJ-818A), mixed 50 min, produce emulsion, stirring speed of 60 rpm;

[0049] (2) The thickener solution was obtained by diluting 7 thickeners (acrylate swelling thickeners, purchased from Roccohas, model TT935), and slowly dripped with thickener solution while stirring the emulsion. The stirring speed was 100 rpm, and the drip speed was about 10 drops / min, and 1.2 parts of thickener dilution was added dropwise;

[0050] (3) Continue while stirring the emulsion side to add 0.24 bentonite and 0.36 parts of gas phase silica, 1.5 parts pH regulator (AMP95, isobutanolam...

Embodiment 2

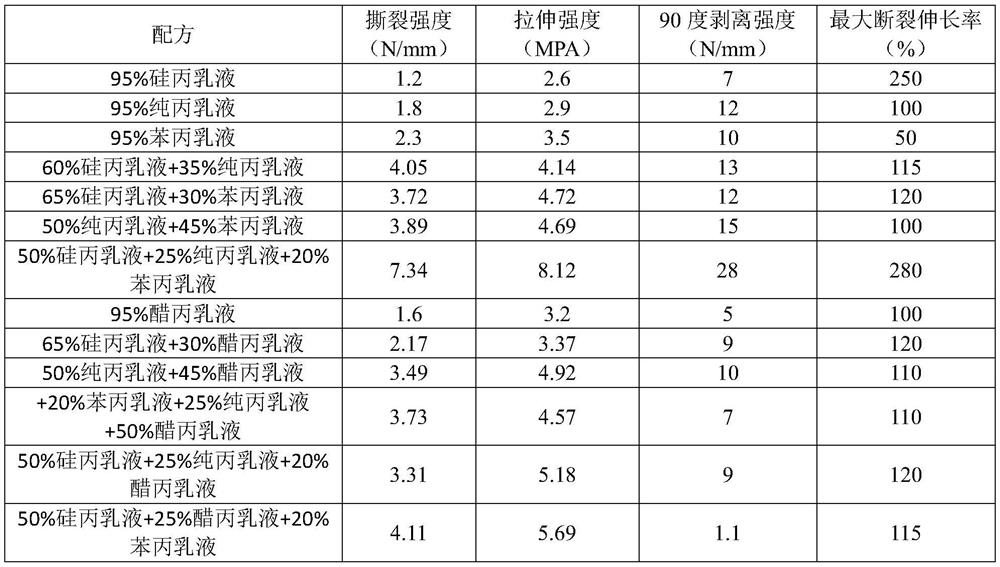

[0051] Effect of Embodiment 2 Different formulations of the acrylic emulsion on the preparation of waterborne peelable coating

[0052] The present embodiment is prepared by preparing a water-resistant peelable coating in Example 1, wherein the acrylic emulsion is prepared by formulating the formulation shown in Table 1, thereby further preparing aqueous peelless coating of different formulations, which will be prepared. The coating is applied to the metal surface, the thickness of 0.2 mm, the torn strength, tensile strength, 90 degree peel strength, maximum elongation of the prepared water-based peelable coating, the maximum elongation, and the detection method of the tear strength reference GB / T 529; Tensile strength detection method reference GB / T 528; method of detection of flexibility reference GB / T 1731; 90 degree peel strength detection method reference GB / T 2792, maximum cleavage elongation detection method reference GB / T 528. The test results are shown in Table ...

Embodiment 3

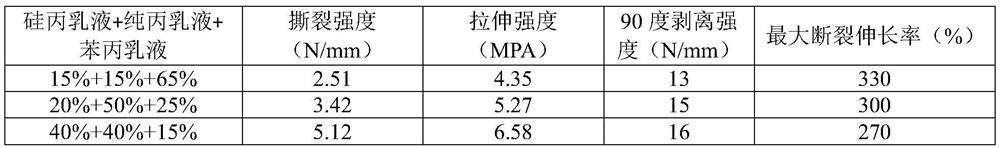

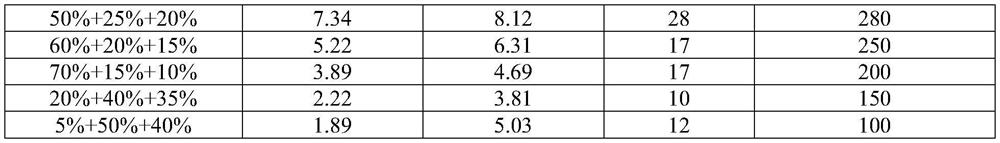

[0058] Example 3 Effects of Silicone Apropylene, Pure Eulfoxia and Phenylbenzoxide Emulsion

[0059] The present embodiment is prepared by the method for preparing a water-proof peelable coating in Example 1, wherein the silicone emulsion, pure extract, and benzole emulsions are prepared by formulating different proportional relationships shown in Table 2, thereby further preparing different water resistance. Stripping the coating, the prepared water-based peelable coating is applied to the metal surface, the thickness of 0.2 mm is applied, and the tension strength, tensile strength, 90 degree peel strength, maximum elongation elongation of the prepared water-based peelable coating is detected. Among them, the detection method of tear strength refers to GB / T 529; Tensile strength detection method reference GB / T 528; method of detection of flexibility reference GB / T1731; 90 degree peel strength detection method reference GB / T 2792; maximum breakage The detection method of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com