Cement raw material decomposition system using alternative fuel

A cement raw material and alternative fuel technology, applied in the direction of furnace type, waste heat treatment, furnace, etc., to achieve the effects of convenient disposal, wide application range and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

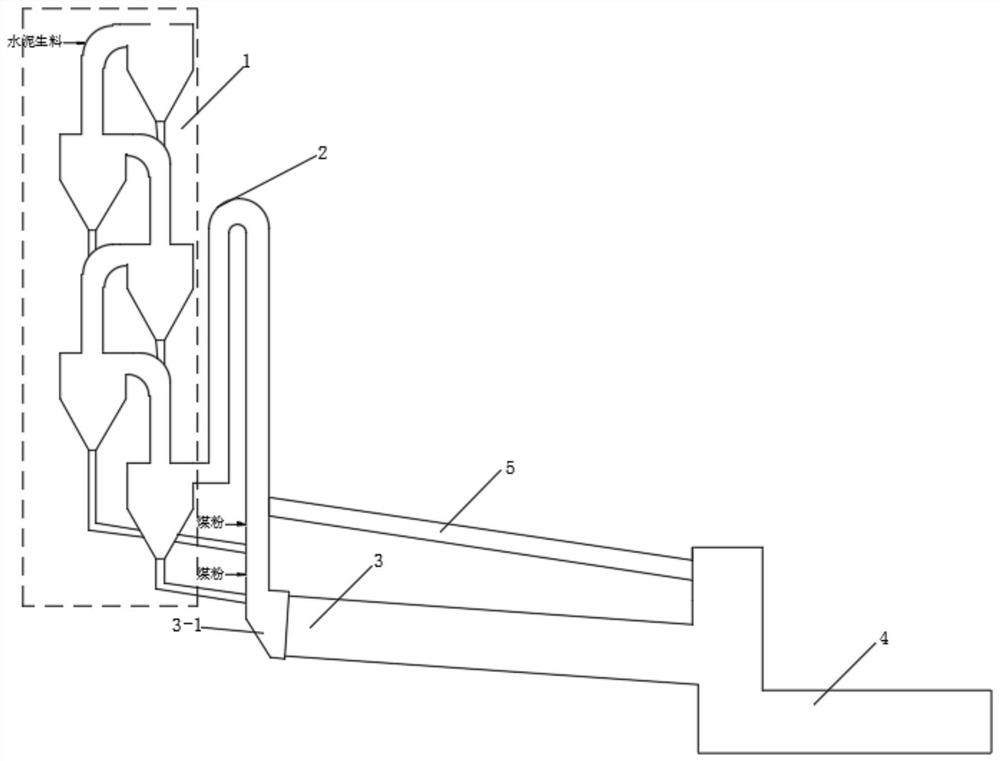

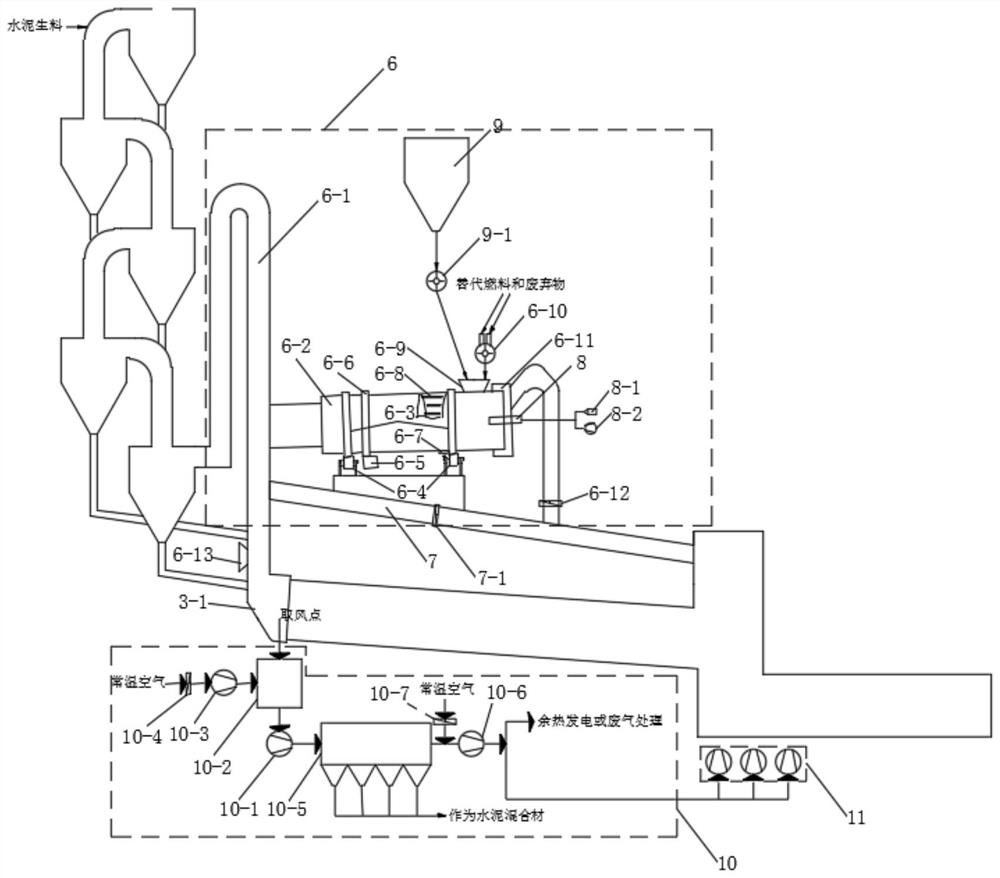

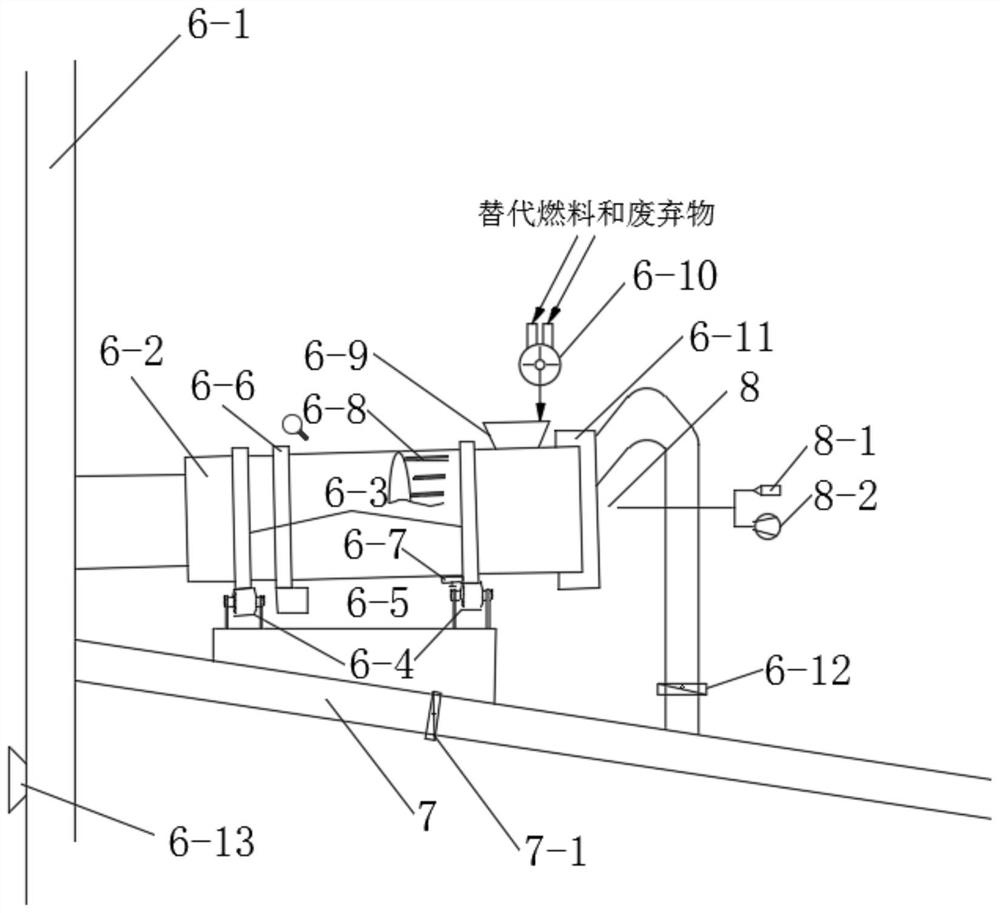

[0047] Such as figure 1 As shown, the most widely used conventional cement production system is mainly composed of cyclone preheater 1, decomposition reactor 2, rotary kiln 3, cooler 4, and tertiary air duct 7. The cyclone preheater 1 is generally composed of 4-6 cyclone separators or cyclone separator groups arranged in random order.

[0048] The decomposition reactor 2 is connected in series between the cyclone preheater 1 and the rotary kiln 3 , the rotary kiln 3 is located between the decomposition reactor 2 and the cooler 4 , and the decomposition reactor 2 and the cooler 4 are also connected through a tertiary air pipe 7 .

[0049] Cement raw meal enters from the top of the cyclone preheater 1, in the cyclone separator, the cement raw meal is separated from the gas, and then enters the lower stage cyclone separator from the bottom of the cyclone separator through the pipeline, and the second last stage from the bottom The bottom of the cyclone separator enters the decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com